Automatic aeroponic vegetable planting and harvesting production line

A production line and vegetable technology, which is applied in the field of facility agriculture automatic planting, can solve the problems of manual operation, low overall level, and inability to form industrialization, etc., and achieve the effects of easy widespread promotion, high production level, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

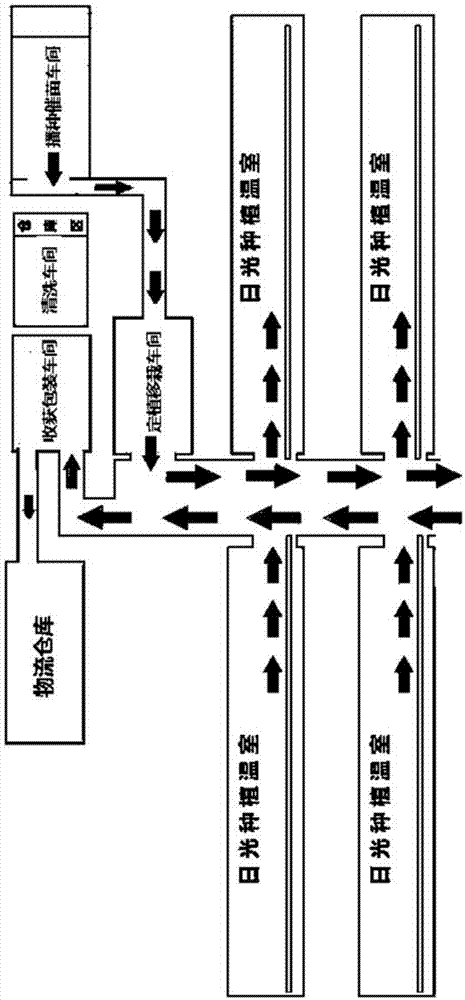

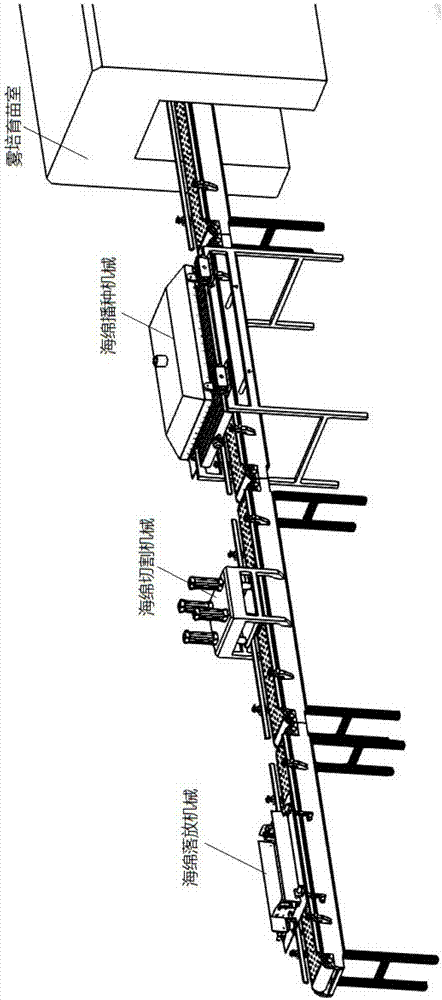

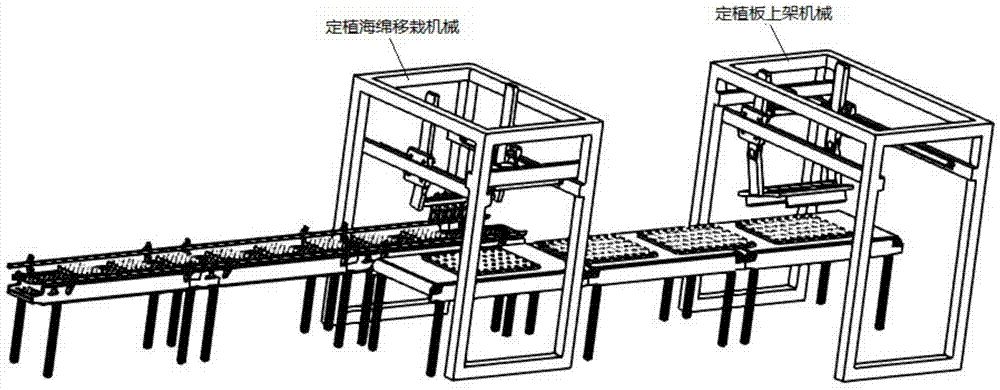

[0033] Such as Figure 1-8 As shown, an automated aeroponic vegetable planting and harvesting production line includes a sowing and accelerating seedling workshop, a planting and transplanting workshop, a solar planting greenhouse, a harvesting and packaging workshop, a cleaning workshop, and a planting frame conveying system; the sowing and accelerating seedling workshop is connected to the planting and transplanting workshop , the planting and transplanting workshop is connected to the solar planting greenhouse, the solar planting greenhouse is connected to the harvesting and packaging workshop, the harvesting and packaging workshop is connected to the cleaning workshop, and the sowing and accelerating seedling workshop is used to sow vegetable seeds in the planting sponge and cultivate them into seedlings; planting and transplanting The workshop is used to transplant the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com