Cylinder structure of hydraulic vertical conveying device

A technology for conveying devices and oil cylinders, applied in the direction of fluid pressure actuating devices, etc., which can solve the problems of potential safety hazards, damage, and increased difficulty of operation for operators, and achieve the effect of ensuring long-lasting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

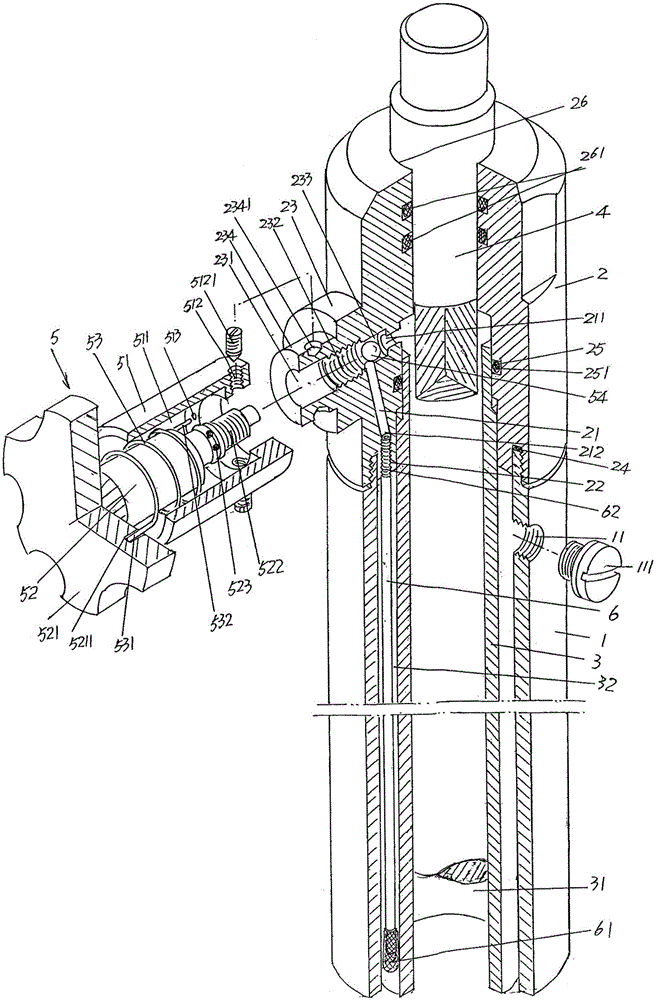

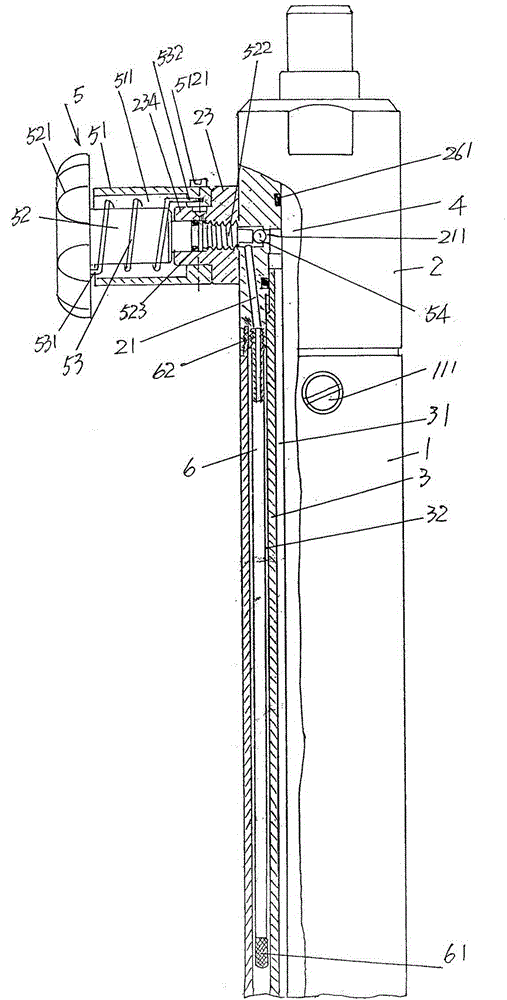

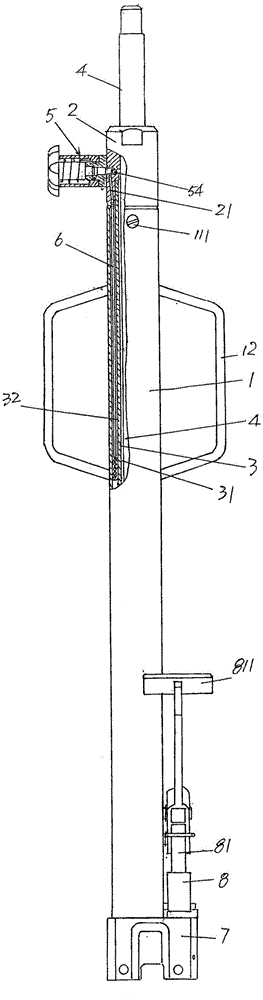

[0024] See figure 1 and figure 2 , provides an outer cover 1, the outer cover 1 is made of metal material, on the outer cover 1 and at the upper part of the outer cover 1, namely the upper end, there is an intake and exhaust screw thread matching hole 11, and in the intake and exhaust screw thread matching hole 11 The position is screwed with an intake and exhaust screw 111 in a threaded fit. A cap 2 is provided, and the top cap 2 is preferably fixed to the upper end of the outer casing 1 in a threaded fitting manner, and a top cap sealing ring 24 is provided at the matching position between the top cap 2 and the outer casing 1 . As shown in the figure, an oil return passage 21 is provided on the top cap 2, because a valve seat 23 that is significantly protruding from the outer wall surface of the top cap 2 is formed on the outer wall of the top cap 2, and the valve seat 23 is located on the top cap. The position on the top cap 2 corresponds to the oil return passage 21, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com