Dual Shaft Rotary Timing Generator

A timing generator and drive shaft technology, which is applied to transmissions, transmission parts, gear transmissions, etc., can solve problems such as the inability to repeat sequential actions continuously, and achieve the effect of increasing the number of continuous rotations and improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

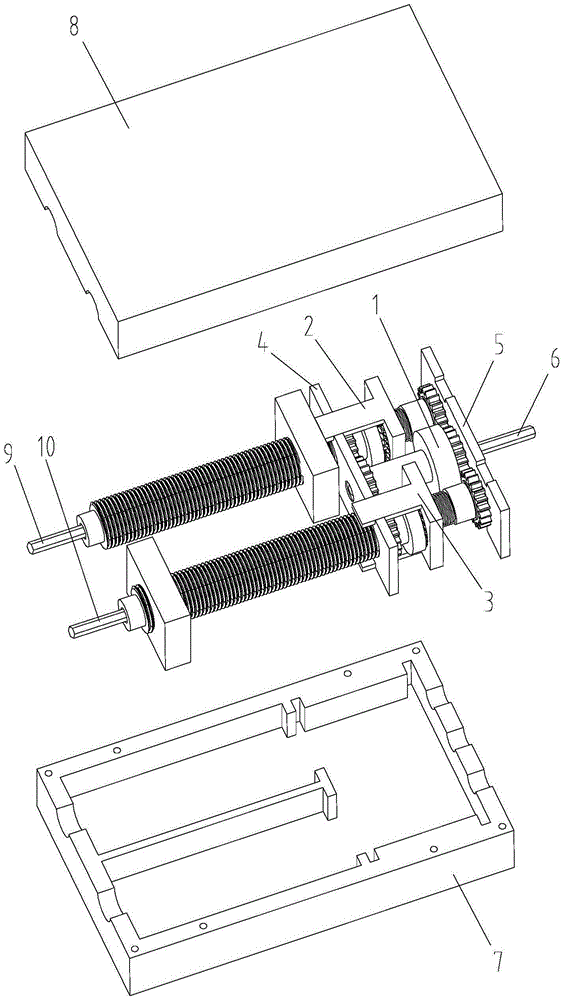

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the dual-shaft rotation timing generator includes a planetary gear clutch 1, a first output device 2, a second output device 3, a first support plate 4, a second support plate 5, a base 7, a top cover 8, The hexagonal main drive shaft 6, the first output shaft 9 and the second output shaft 10, the base 7 and the top cover 8 are fastened into one housing, the planetary gear clutch 1, the first output device 2, the second output device 3, Both the first support board 4 and the second support board 5 are arranged in the housing. The input end of the planetary gear clutch 1 is in transmission connection with a total drive shaft 6. The planetary gear clutch 1 is provided with two output ends, and the first output device 2 and the second output device 3 are respectively provided with a timing locking member and a driving member. , one output end of the planetary gear clutch 1 is simultaneously connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com