Torch Deflagration Ignition Safety System

A safety system and deflagration technology, which is applied in the field of torch deflagration ignition safety system, can solve problems such as burnt catalyst, valve internal leakage, explosion, etc., and achieve the effects of preventing mutual channeling, ensuring safety, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

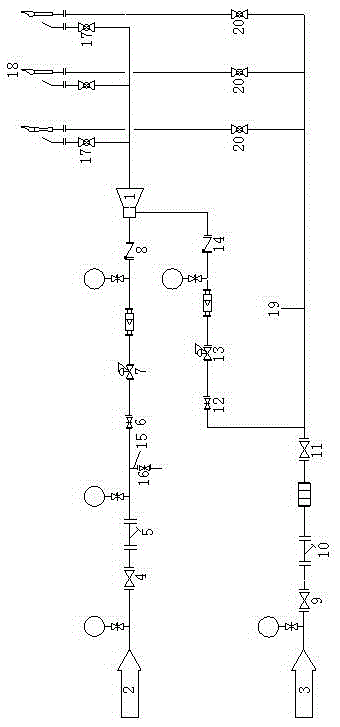

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes the instrument air pipe 2 and the coke oven gas pipe 3 respectively connected to the mixer 1 through pipelines, and the pipeline connecting the instrument air pipe 3 to the mixer 1 is provided with a valve A4, a filter A5, a valve B6, and a pressure regulating valve in sequence. Valve E9, filter B10, flame arrester, valve D11, valve C12, pressure regulating valve B13, check valve B14, valve A4 There is a short connecting pipe 15 connected to the pipeline between the valve B6, and a valve F16 is installed on the short connecting pipe 15; several branch pipelines are arranged on the mixer 1, and ball valve A17 is installed on the branch pipeline, and the end of the branch pipeline is close to the long light 18: The connecting pipe between the coke oven gas pipe 3 and the mixer 1 is provided behind the valve D11 with a parallel branch pipe 19 connected to the permanent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com