A bare wire type small inertia thermocouple

A thermocouple and inertial technology, which is applied in the field of bare wire small inertial thermocouples, can solve the problems of increasing production costs, prone to fatigue fractures, and affecting the safety of engine testing, so as to reduce consumption, increase stability and bend resistance ability, the effect of increasing the degree of turbulence and heat release coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

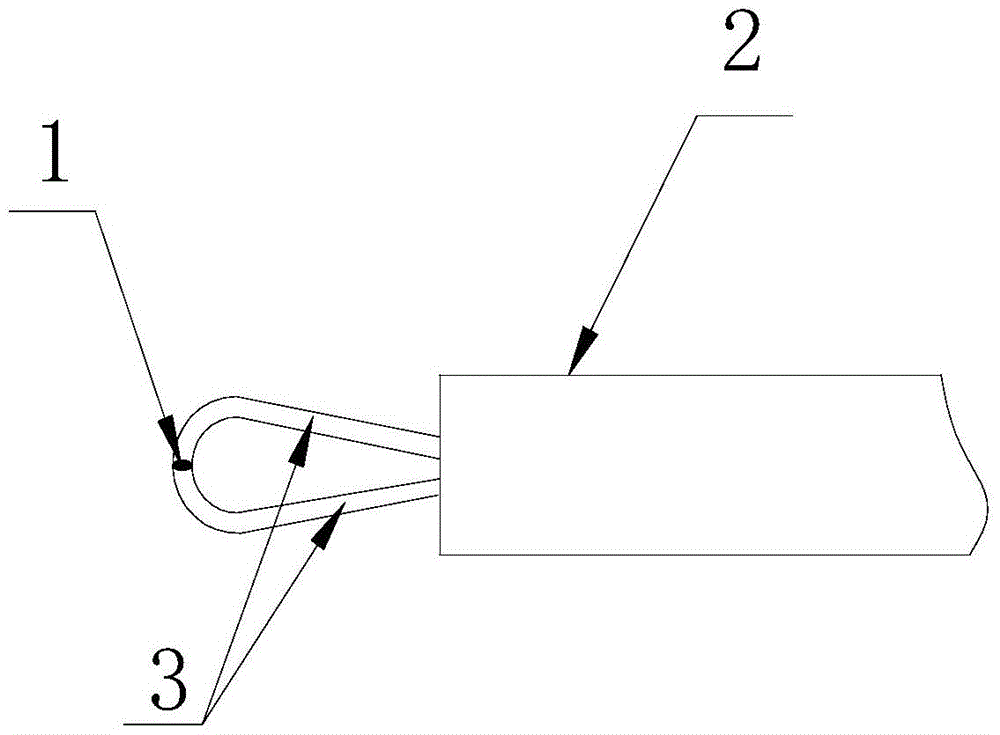

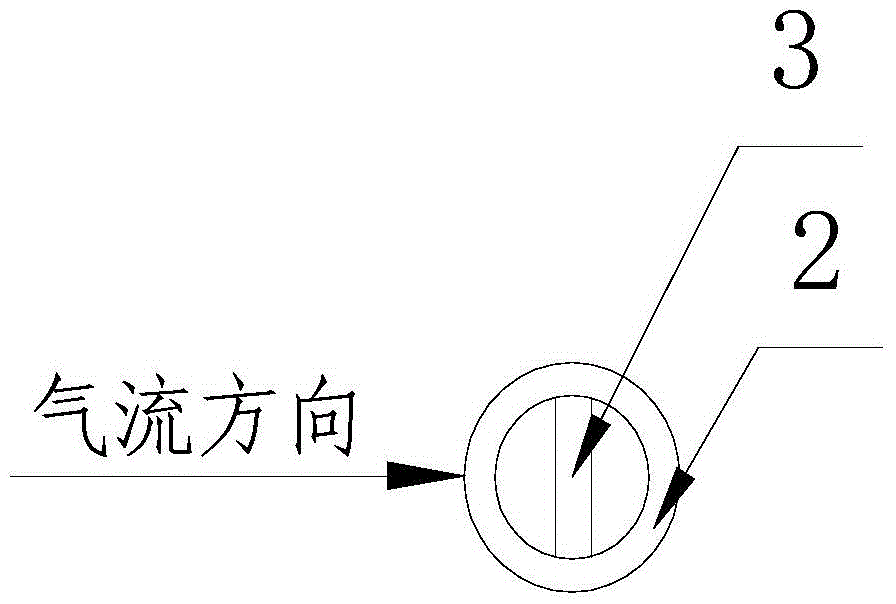

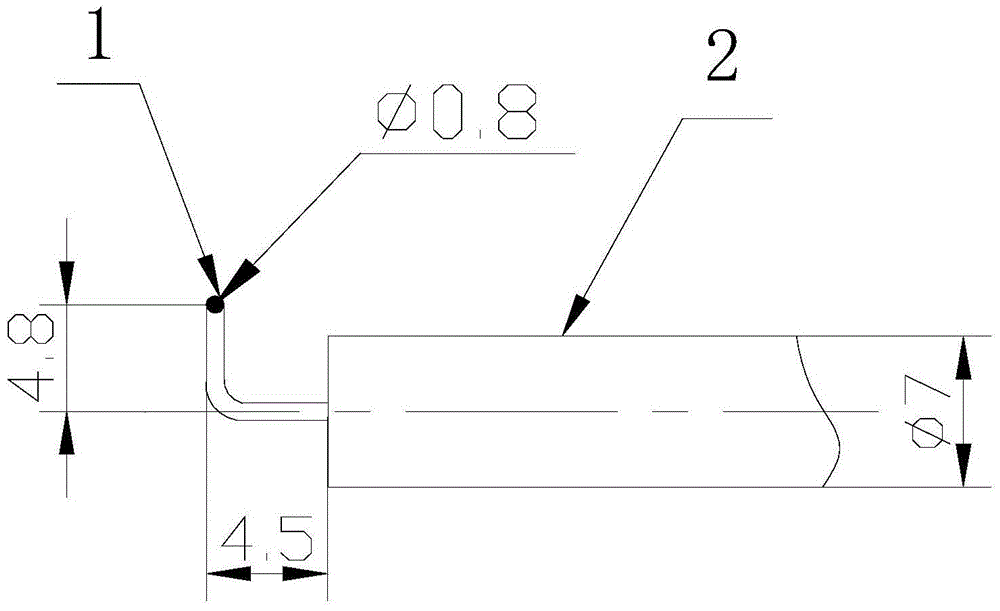

[0017] Such as image 3 , 4 , 5, a bare wire type small inertial thermocouple, including a thermocouple protective cover 2 and a thermal electrode 3, the temperature measuring end of the thermal electrode 3 facing the direction of the airflow is "n" type that is wide on the outside and narrow on the inside; The temperature measuring end of the thermal electrode 3 is folded up along the middle part parallel to the side where the thermal junction 1 is located to form a right angle, so that the side where the hot junction 1 is located faces the direction of air flow; wherein, the folded end is perpendicular to the center of the thermocouple protective sleeve 2 line, and the other end is perpendicular to the folded end.

[0018] The diameter of the thermal electrode 3 is 0.8 mm, the vertical distance between the bending point of the the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com