Method for testing reactive compensation device without dismounting leads

A compensating device and lead wire technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of time-consuming, laborious, long-term, easy to appear safety hazards, etc., to reduce maintenance costs, find and eliminate safety hazards. , the effect of ensuring the reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

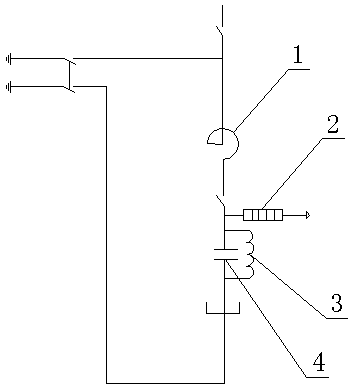

Image

Examples

Embodiment 1

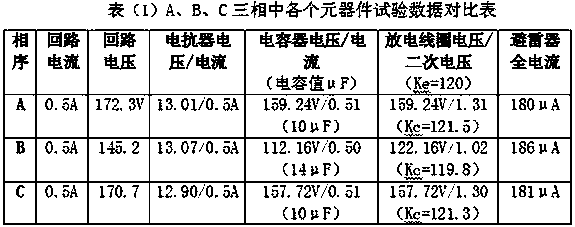

[0030] Using the method of testing the reactive power compensation device without removing the lead wires of the present invention to detect the reactive power compensation device in a 35KV substation includes the following steps:

[0031] 1) Test phase A: introduce the AC operating voltage into the reactive power compensation device, and use a peak clamp ammeter to measure the full current of the arrester to be 180μA;

[0032] 2) Disconnect the AC operating voltage of the reactive power compensation device, add AC test voltage to both ends of the reactive power compensation device, so that the current of the circuit reaches 0.5A, and the detection circuit voltage is 172.3V;

[0033] 3) Use a voltmeter and an ammeter to test the voltage and current at both ends of the reactor for three times, and the results of the three tests are 13.01V, 0.5A; 13.04V, 0.5A; 12.96V, 0.5A;

[0034] 4) Use a voltmeter and an ammeter to test the voltage and current at both ends of the capacitor f...

Embodiment 2

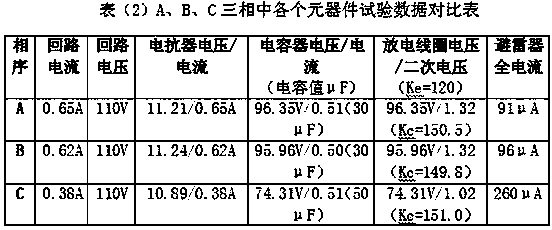

[0043] Using the method of testing the reactive power compensation device without removing the lead wires of the present invention to detect the reactive power compensation device in a certain 110KV substation includes the following steps:

[0044] 1) Test phase A: introduce the AC operating voltage into the reactive power compensation device, and use a peak clamp ammeter to measure the full current of the arrester to be 91μA;

[0045] 2) Disconnect the AC operating voltage of the reactive power compensation device, add 110V AC test voltage to both ends of the reactive power compensation device, and the detection circuit current is 0.65A;

[0046] 3) The voltage and current at both ends of the reactor were tested three times with a voltmeter and an ammeter, and the results of the three tests were 11.21V, 0.65A; 11.23V, 0.64A; 11.19V, 0.66A;

[0047] 4) Use a voltmeter and an ammeter to test the voltage and current at both ends of the capacitor for three times, and the results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com