Pressure-tolerant wire clamp special for carbon fiber guide wire

A technology of carbon fiber wires and pressure-resistant wires, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of affecting the transmission capacity of the power grid, prone to sag, and loose strands of wires, so as to improve connection reliability, avoid self-wear, and improve The effect of clamping degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

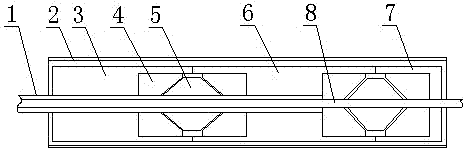

[0015] As a preferred solution of the present invention, both the structural member 4 and the shuttle-shaped collet 5 are made of hard aluminum-magnesium alloy.

[0016] As a further preferred solution of the present invention, the front end of the compression tube 3 with a groove at one end is a compressible deformation zone.

[0017] As a further preferred solution of the present invention, the middle part of the compression tube 6 with grooves at both ends is a compressible deformation zone.

[0018] Further preferably, in the solution of the present invention, the outer sleeve 2 is a compressible deformable tube.

[0019] As a further preferred solution of the present invention, the outer sleeve 2 is an insulating sealing tube.

[0020] A special pressure-resistant clamp for carbon fiber wires according to the present invention, by setting a compression tube 3 with a groove at one end, a compression tube 6 with grooves at both ends, and an end tube 7 with grooves, the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com