Vertical numerically-controlled milling machine

A CNC milling machine and vertical technology, applied in the field of CNC machine tools, can solve problems such as unfavorable clamping, affecting the translation accuracy of the nut pair, reducing the machining accuracy, etc., to avoid excessive clamping, without frequent cleaning, and improve the machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

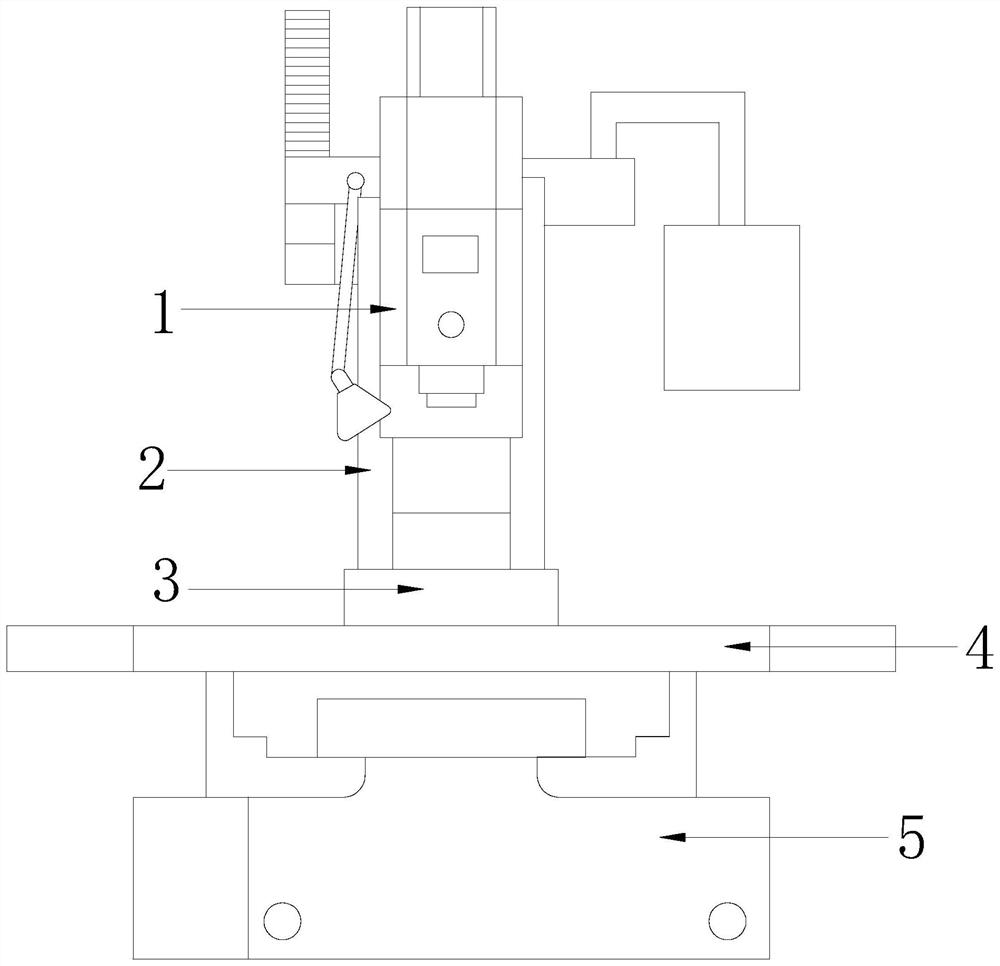

[0029] see Figure 1-7 , The present invention provides a technical scheme of a vertical CNC milling machine: its structure includes a spindle box 1, a body 2, a chuck 3, a worktable 4, and a base 5, the base 5 is fixedly connected with the body 2, and the body 2 A worktable 4 is installed thereon, and the worktable 4 is provided with a chuck 3 , and the chuck 3 is located below the spindle box 1 , and the spindle box 1 is connected to the body 2 .

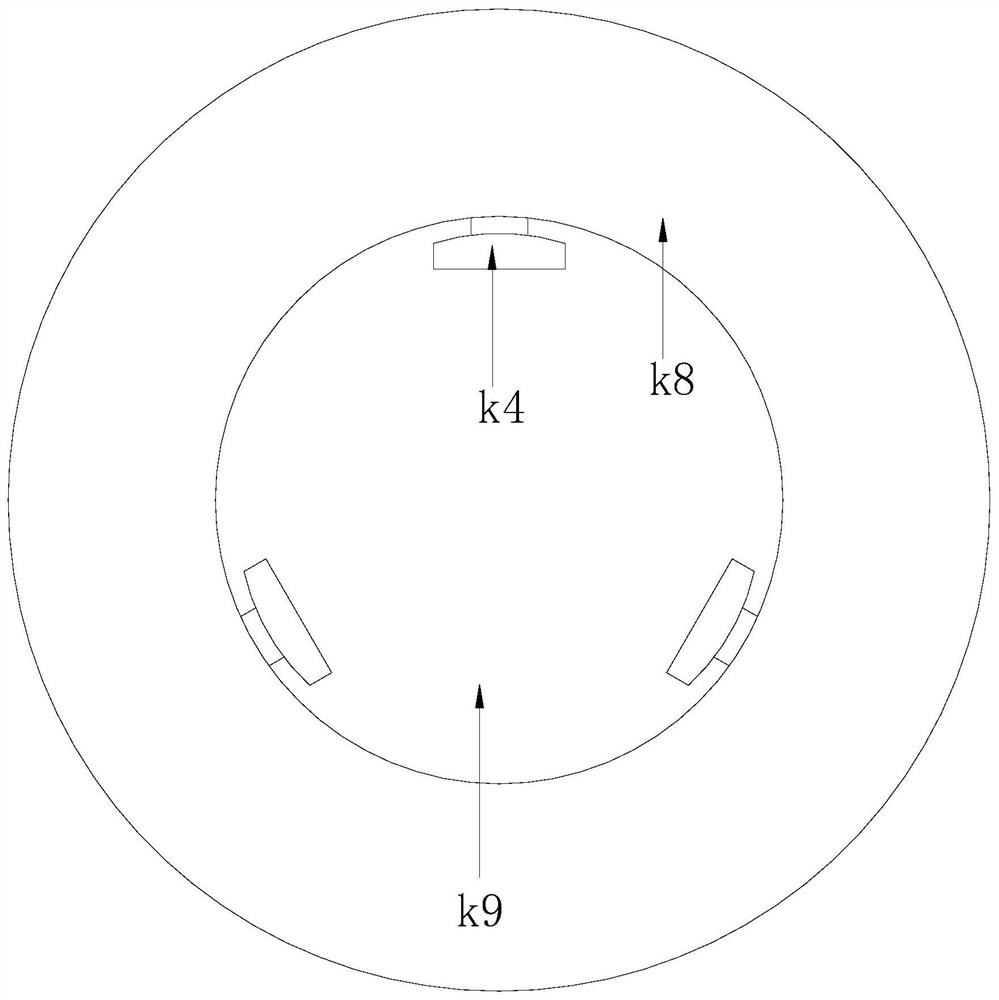

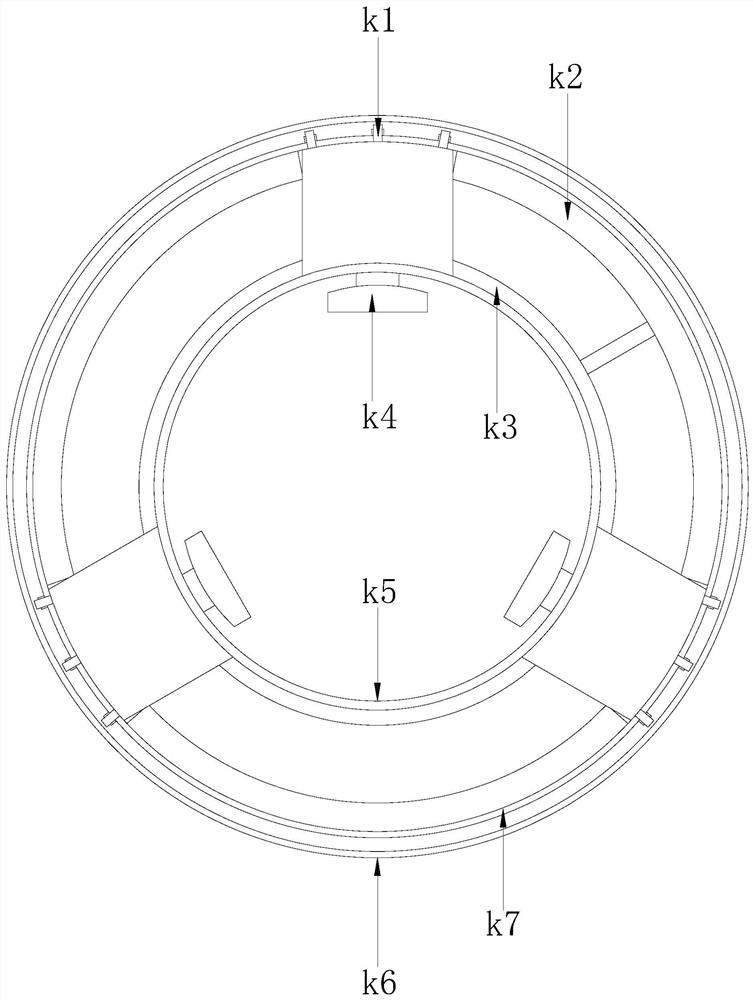

[0030] The chuck 3 includes a liquid storage assembly k1, a pumping ring k2, an inner tube k3, a clamping group k4, an inner ring k5, an outer ring k6, a limit ring k7, a top ring k8, and a bottom plate k9. The bottom plate k9 is connected, the inner ring k5 and the outer ring k6 are fixed on the bottom plate k9, the inner ring k5 and the outer ring k6 are arranged in a concentric structure circle structure, and the tops of the inner ring k5 and the outer ring k6 are connected to the top ring k8, the annular cavity formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com