Pressing type grounding wire joint connecting device

A joint connection and grounding wire technology, which is applied in the direction of clamping/spring connection, multi-core cable end parts, etc., can solve the problems that the grounding wire is easy to fall off during the assembly process, the labor intensity of the operator is high, and the grounding wire is loose and falling. , to shorten the assembly time, avoid the loss of parts, and prevent the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

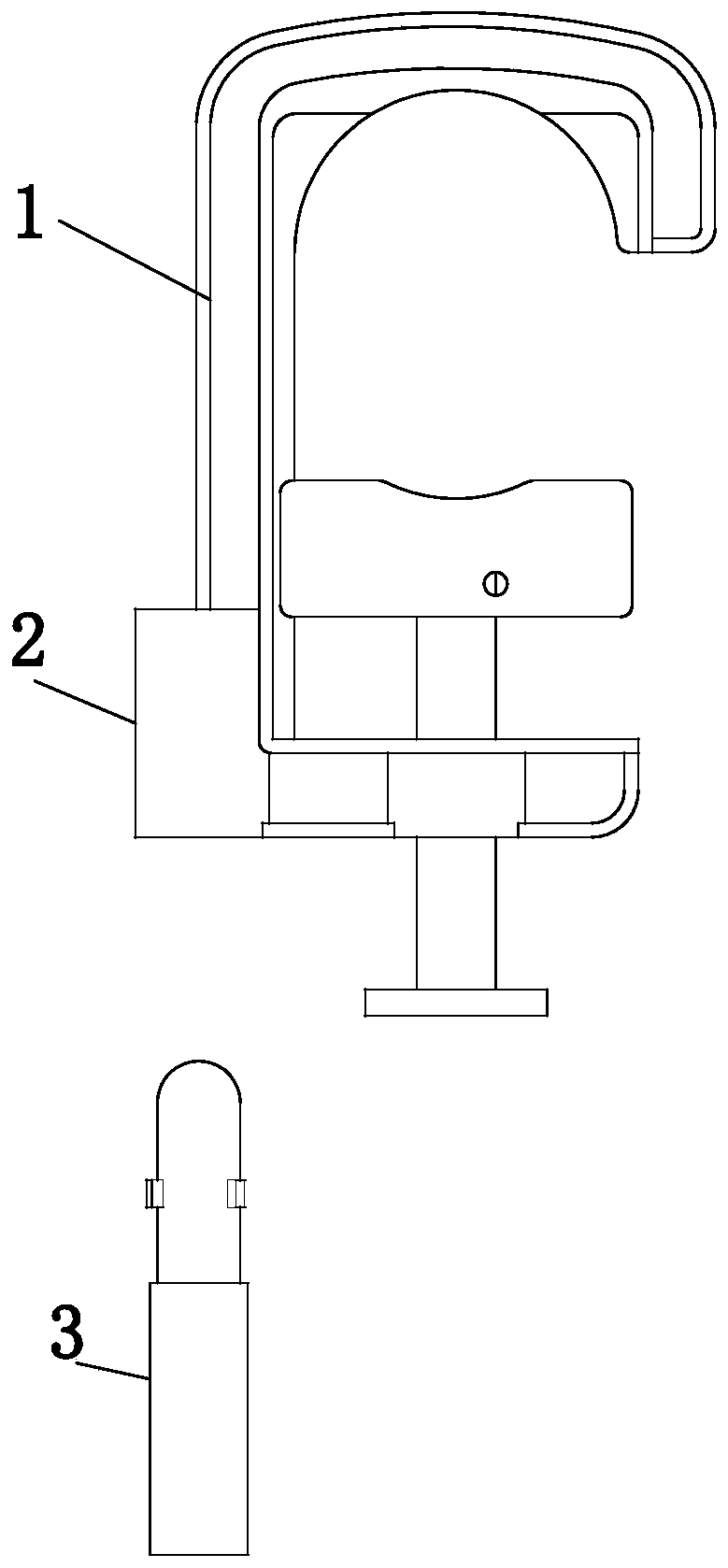

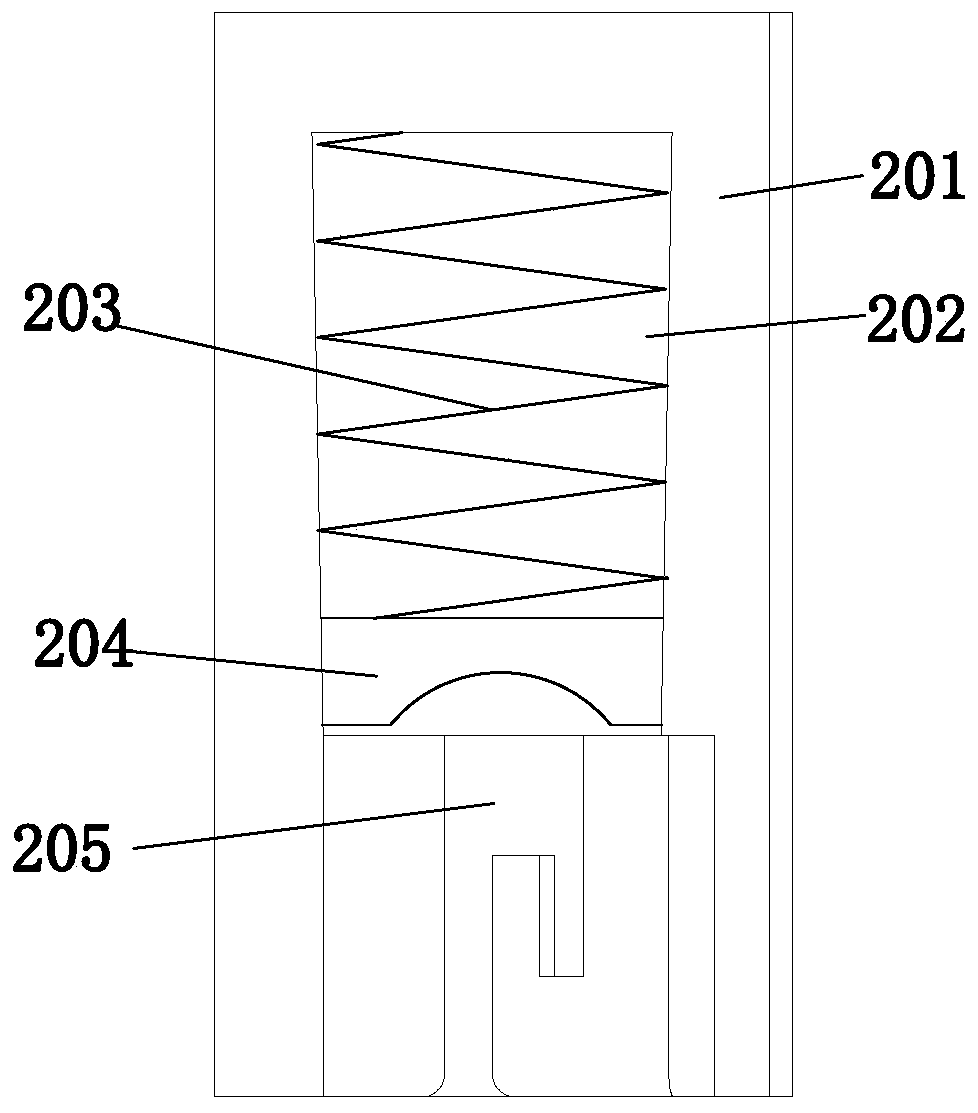

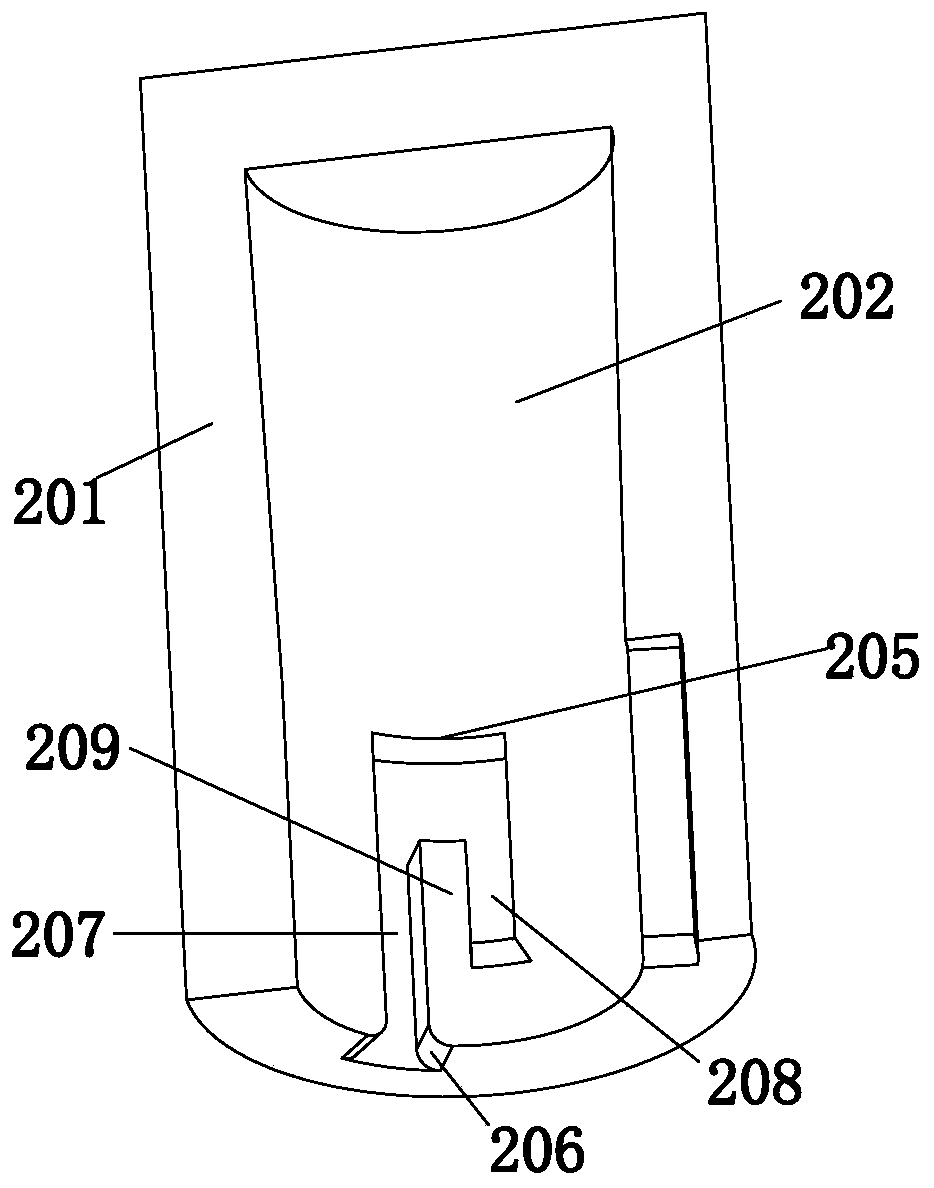

[0026] Example. A push-type grounding wire joint connection device, which is composed of Figure 1 to Figure 7 As shown, it includes wire clamp 1, the bottom of wire clamp 1 is provided with fixed contact 2, fixed contact 2 is provided with movable contact 3, and the bottom of movable contact 3 is connected with grounding wire; the fixed contact 2 includes fixed on The cylinder body 201 at the bottom of the wire clip 1 has a socket 202 at the bottom of the cylinder 201, an extrusion spring 203 is arranged inside the socket 202, and a contact finger 204 is arranged below the extrusion spring 203, and the inner wall of the bottom of the socket 202 is evenly distributed There are a plurality of snap-in slots 205; the movable contact 3 includes an upper plug 301, the bottom of the upper plug 301 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com