Radiator shutter device

A louver device and radiator technology, which is applied to heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of easily damaged rotating blades, unbalanced left and right, and shaft rust, so as to improve the clamping degree , Improve the effect of tension and compression bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

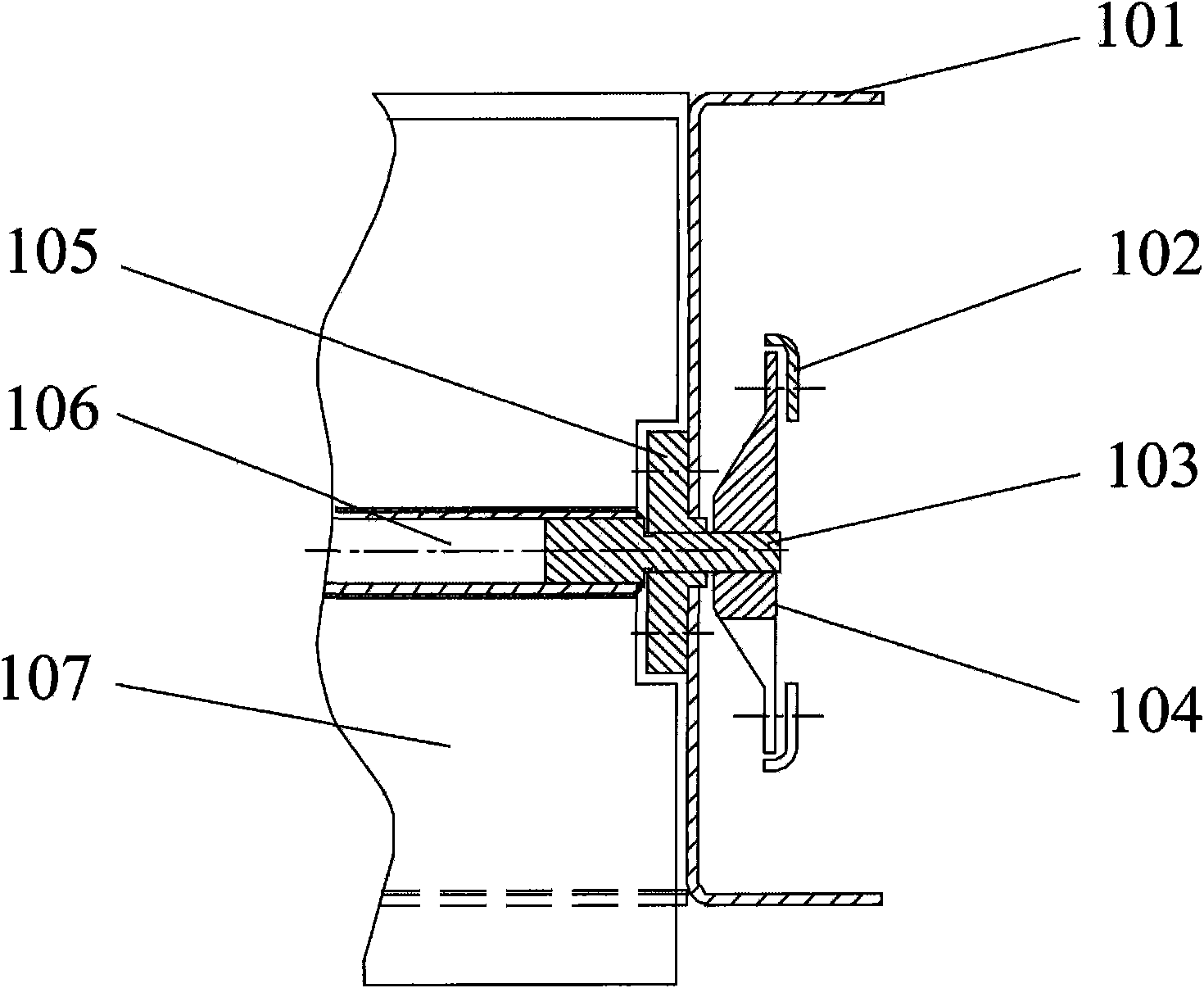

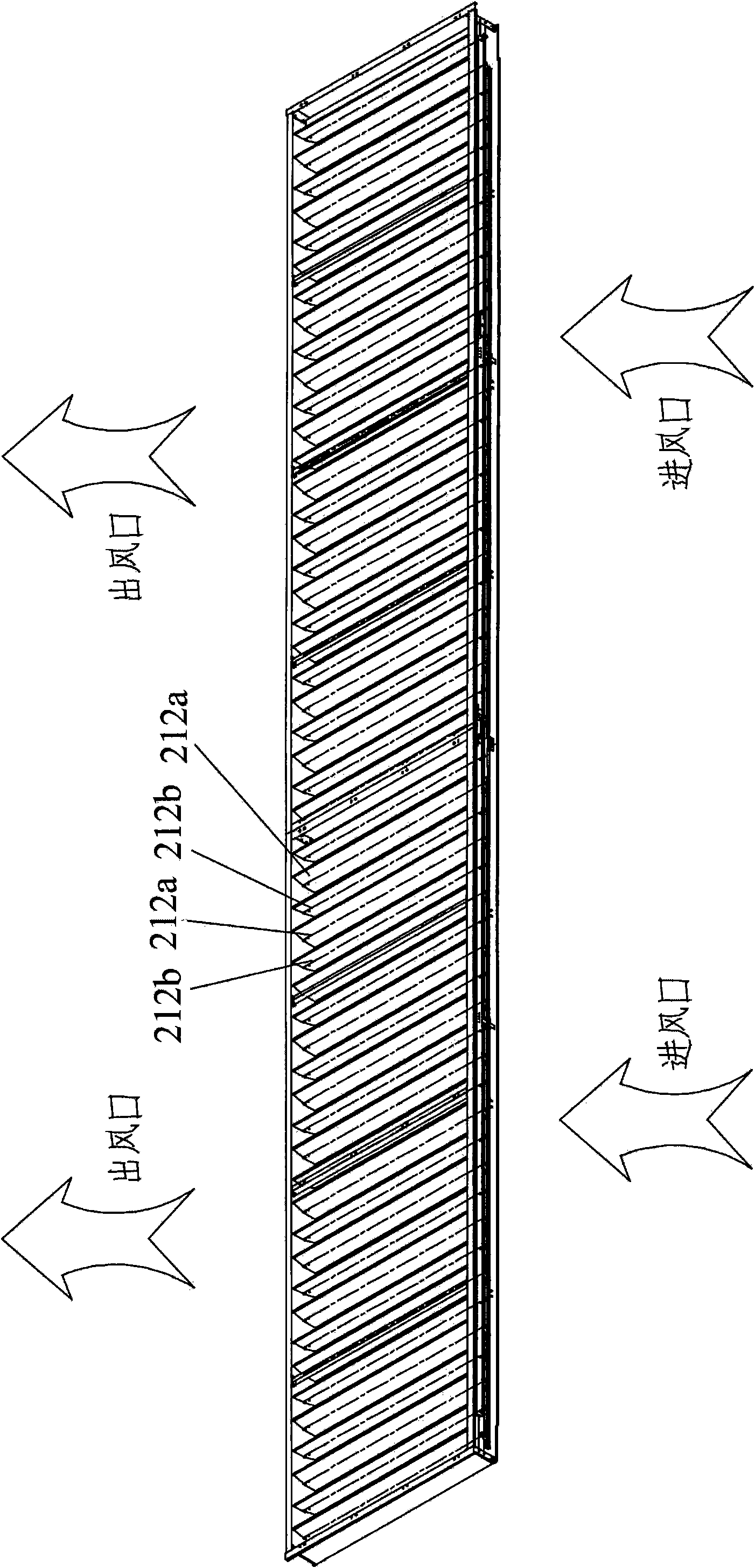

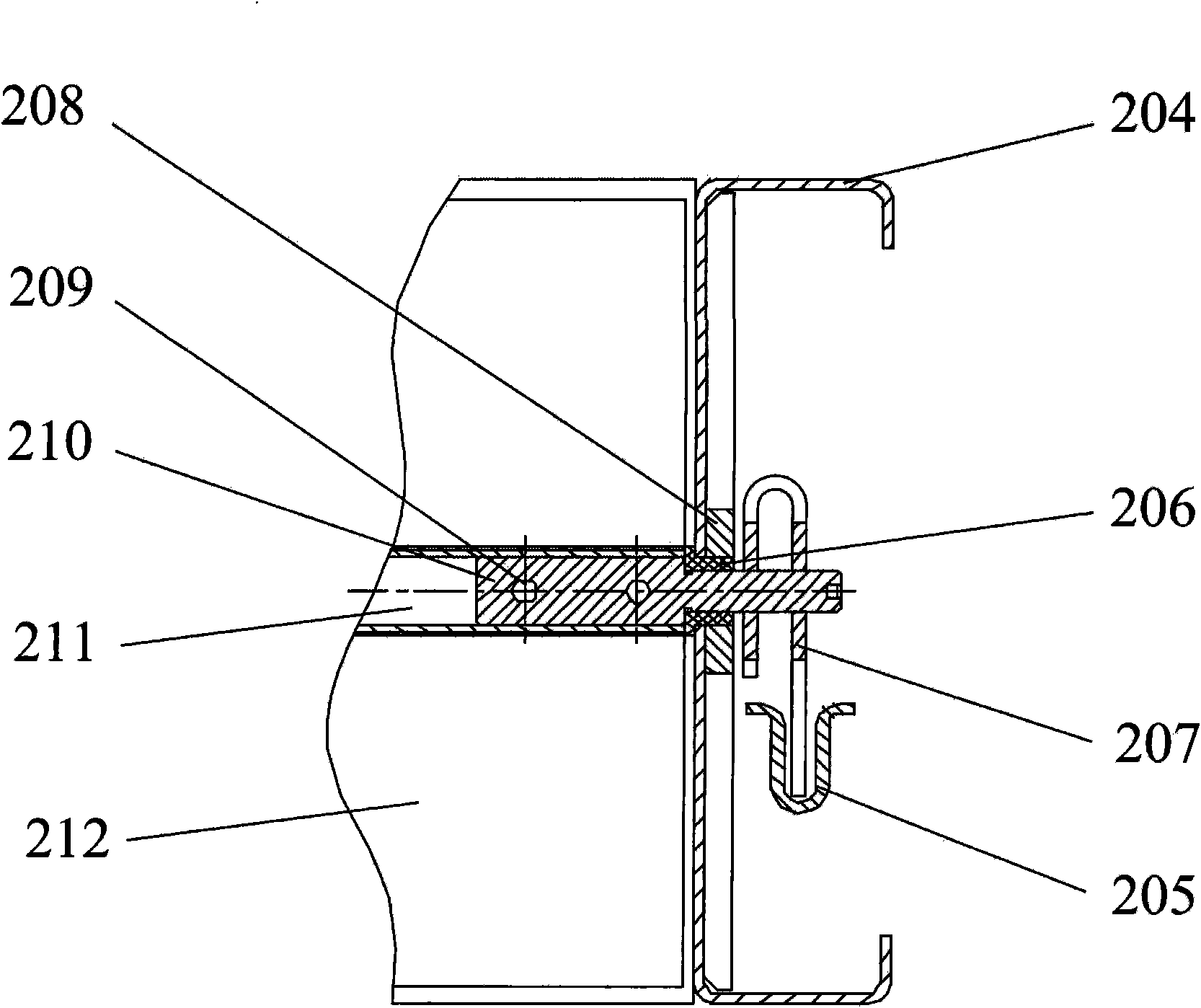

[0037] Such as figure 2 and image 3 As shown, the radiator shutter device of this embodiment includes: a frame 204 , blades 212 , guide rods 207 and pull rods 205 .

[0038] Wherein, the blade 212 has first blades 212 a and second blades 212 b arranged alternately, and all the blades are rotatably arranged on the frame 204 through corresponding blade shafts 210 .

[0039] Guide rod 207 is arranged at one or both ends corresponding to each impeller shaft 210, such as Figure 4 As shown, the guide bar 207 has a first guide bar 207a corresponding to the first vane 212a and a second guide bar 207b corresponding to the second vane 212b.

[0040] Such as Figure 4 As shown, tie rod 205 has a first tie rod 205a connecting all first guide rods 207a and a second tie rod 205b connecting all second guide rods 207b. The first pull rod 205a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com