Transport method of microorganisms

A technology of microbial bacteria and containers, applied in the field of transportation of microbial bacteria, can solve problems such as reduction and loss of microbial enzyme catalytic ability, and achieve the effect of reducing cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2、 comparative example 1

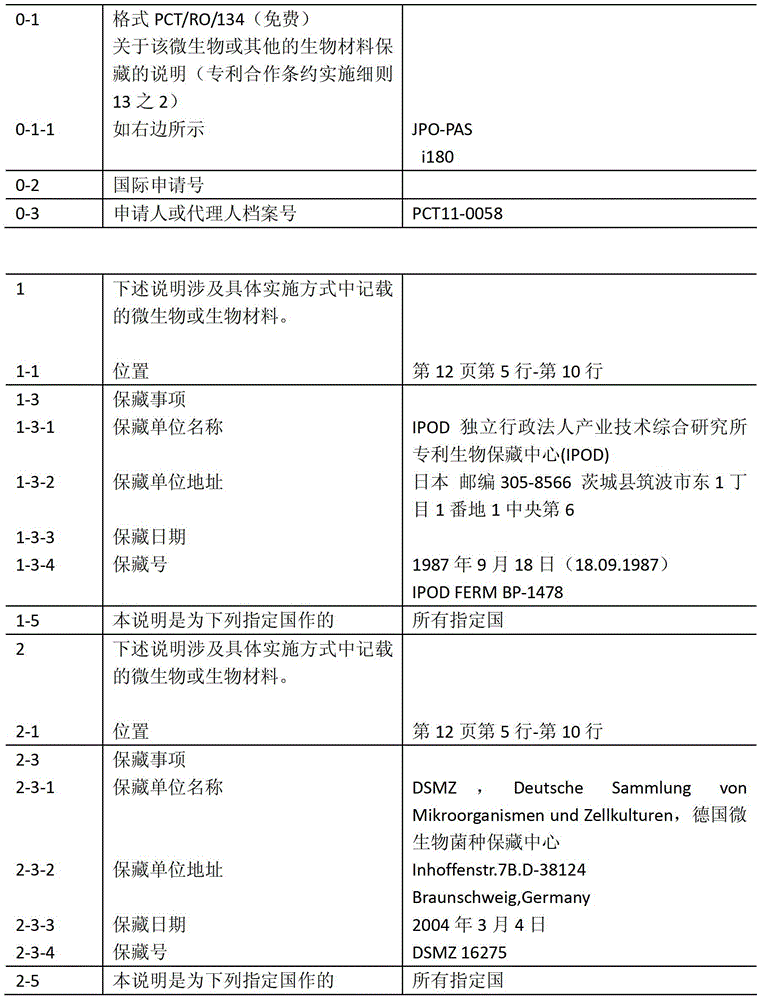

[0038] to cultivate

[0039] Rhodococcus rhodochrous J-1 strain (Rhodococcus rhodochrous J-1: FERMBP-1478) having nitrile hydratase activity was used to contain 2% by mass of glucose, 1% by mass of urea, 0.5% by mass of peptone, 0.3% of yeast extract, and 0.05% of cobalt chloride. Mass % medium (pH 7.0) was used for aerobic culture.

[0040] Preparation of bacterial cell suspension for preservation

[0041] The cultured microbial cells were recovered by centrifugation (12000 rpm, 20 minutes), and washed with a 0.1% sodium acrylate aqueous solution (pH 7.0). The above-mentioned aqueous solution was added to the washed bacterial cells to obtain a bacterial cell suspension (10% by mass as dry bacterial cells).

[0042] Preservation of bacterial suspension

[0043] Add 115mL (Example 1) and 70mL (Comparative Example 1) of the bacterial cell suspension prepared by the above method into a polyethylene container with a total volume of 120mL, seal it, and shake it at 30°C and 120rp...

Embodiment 3

[0048] Embodiment 3, comparative example 2

[0049] Preparation of transformant with nitrile hydratase derived from Rhodococcus rhodochrous strain M8

[0050] (1) Preparation of chromosomal DNA of Rhodococcus rhodochrous M8 strain (hereinafter referred to as M8 strain.)

[0051] The M8 strain (SU1731814) can be obtained from the Russian strain center IBFM (VKPMS-926).

[0052] M8 strain was dissolved in 100mL of MYK (0.5% polypeptone, 0.3% Bacto yeast extract, 0.3% Bacto malt extract, 0.2% K 2 HPO 4 , 0.2%KH 2 PO 4 ) medium (pH 7.0), cultured with shaking at 30°C for 72 hours. Centrifuge the culture medium, and suspend the collected cells in 4 mL of Saline-EDTA solution (0.1 MEDTA, 0.15 M NaCl (pH 8.0)). 8 mg of lysozyme was added to the suspension, shaken at 37°C for 1 to 2 hours, and then frozen at -20°C.

[0053] Next, 10 mL of a Tris-SDS solution (1% SDS, 0.1M NaCl, 0.1M Tris-HCl (pH 9.0)) was added to the suspension while shaking it steadily. Further, proteina...

Embodiment 4、 comparative example 3

[0090] to cultivate

[0091] Pseudomonas marginalis DSM16275 strain (Pseudomonas marginalis DSM16275) having nitrile hydratase activity was used to contain 0.2% by mass of glycerin, 0.05% by mass of citric acid, 0.15% of yeast extract, 0.3% by mass of potassium dihydrogenphosphate, and 0.7% by mass of dipotassium hydrogenphosphate. %, 0.0004% by mass of iron sulfate, 0.01% by mass of manganese sulfate, 1.25% by mass of methylurea, and 0.001% by mass of cobalt chloride (pH 7.0) for aerobic culture.

[0092] Preparation of bacterial cell suspension for preservation

[0093] The cultured microbial cells were recovered by centrifugation (12000 rpm, 20 minutes), and washed with a 0.1% sodium acrylate aqueous solution (pH 7.0). The above-mentioned aqueous solution was added to the washed bacterial cells to obtain a bacterial cell suspension (10% by mass as dry bacterial cells).

[0094] 100 mL (Example 4) and 80 mL (Comparative Example 3) of the bacterial cell suspension prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com