A Hedge Trimmer Bearing Mechanism With Adaptive Function

A technology of hedge trimmer and bearing mechanism, applied in the direction of hedge trimming equipment, etc., can solve the problems of poor stability of the trimmer, easy damage of hinge points, rollover of the mechanism, etc., to ensure stability, high movement sensitivity, The effect of high stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it according to the description. The protection scope of the present invention is not limited to the specific embodiments of the present invention.

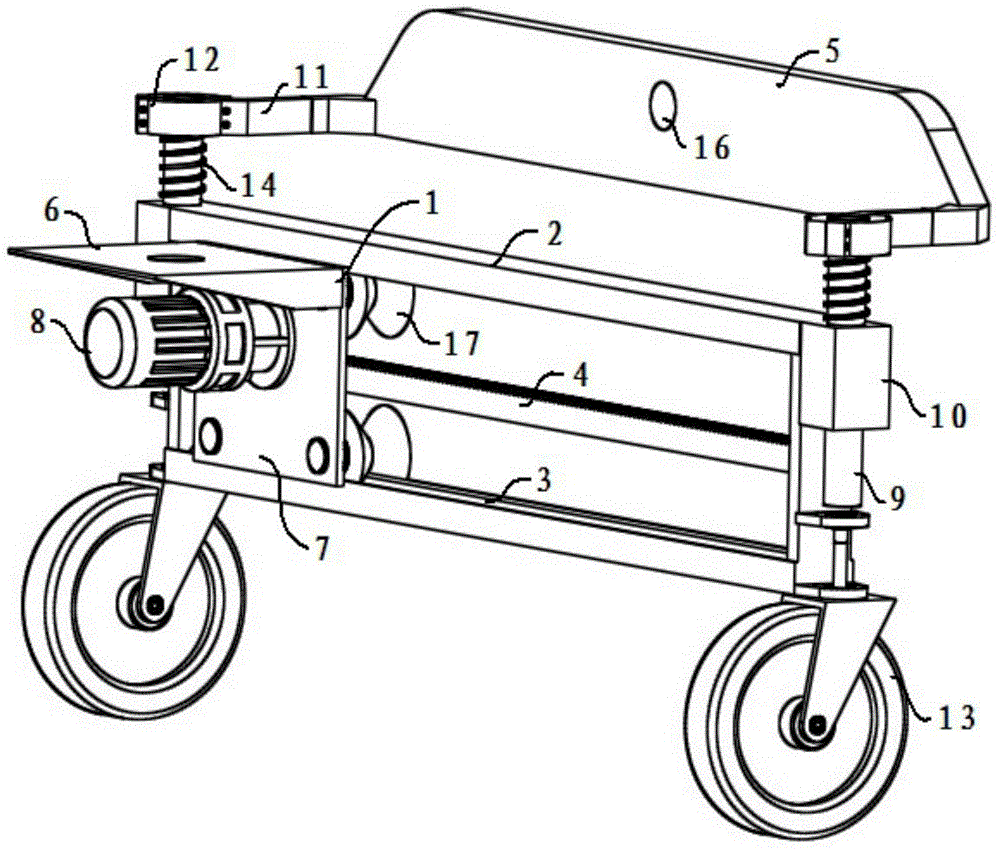

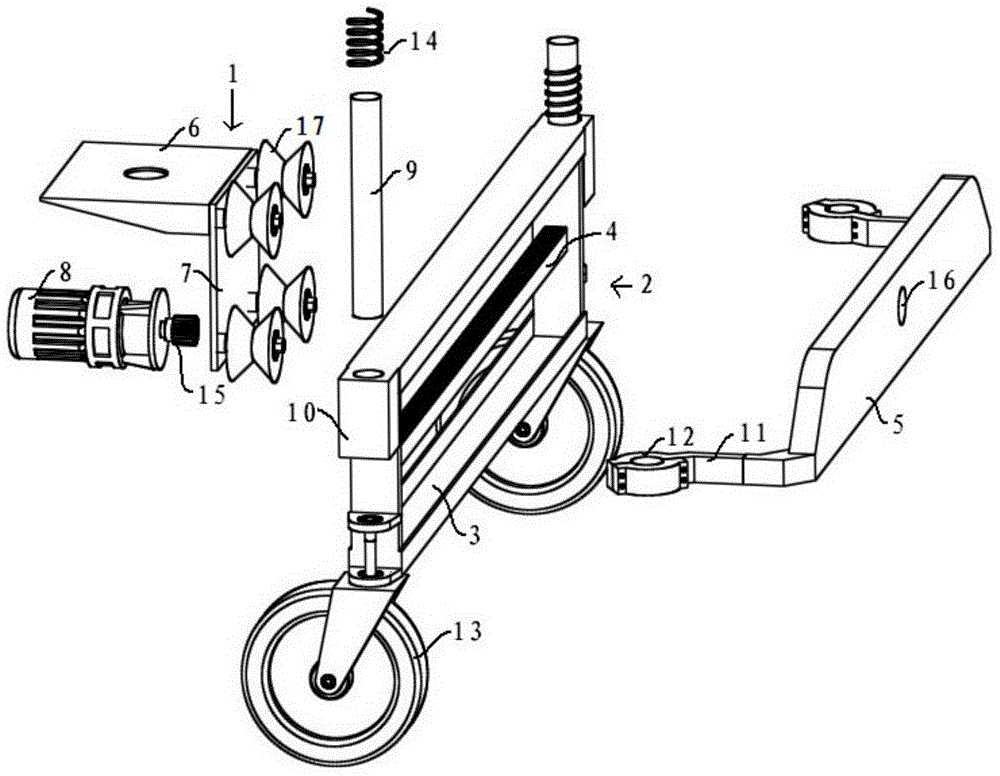

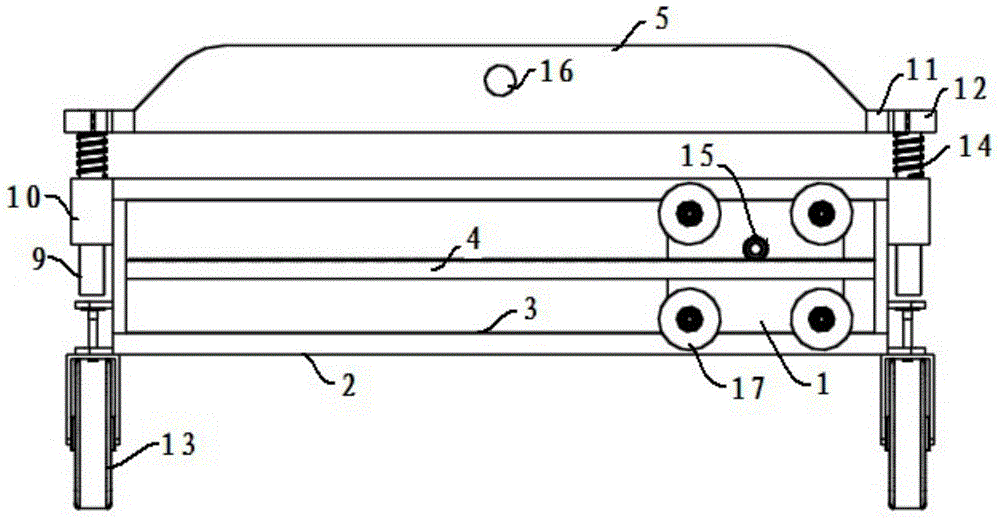

[0029] Such as Figure 1-4 As shown, a hedge trimmer carrying mechanism with self-adaptive function comprises: mounting bracket 5, main bearing bracket 2, bearing platform 1, bearing device 13; Circular connecting hole 16, said circular connecting hole 16 is movably connected with the front or the rear of the carrying vehicle 18, preferably hinged, when the road surface on which the carrying vehicle 18 travels is uneven, the mounting bracket 5 will swing along with it, and will not The phenomenon that the connection point between the mounting bracket 5 and the carrying vehicle 18 is damaged, the two sides of the mounting bracket 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com