Stone side flowerpot and manufacturing method

A production method and technology of flower pots, which are applied in botany equipment and methods, horticulture, container cultivation, etc., can solve the problems of small bonding area, inability to move, easy degumming, etc., and achieve the effect of large sticking area and not easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

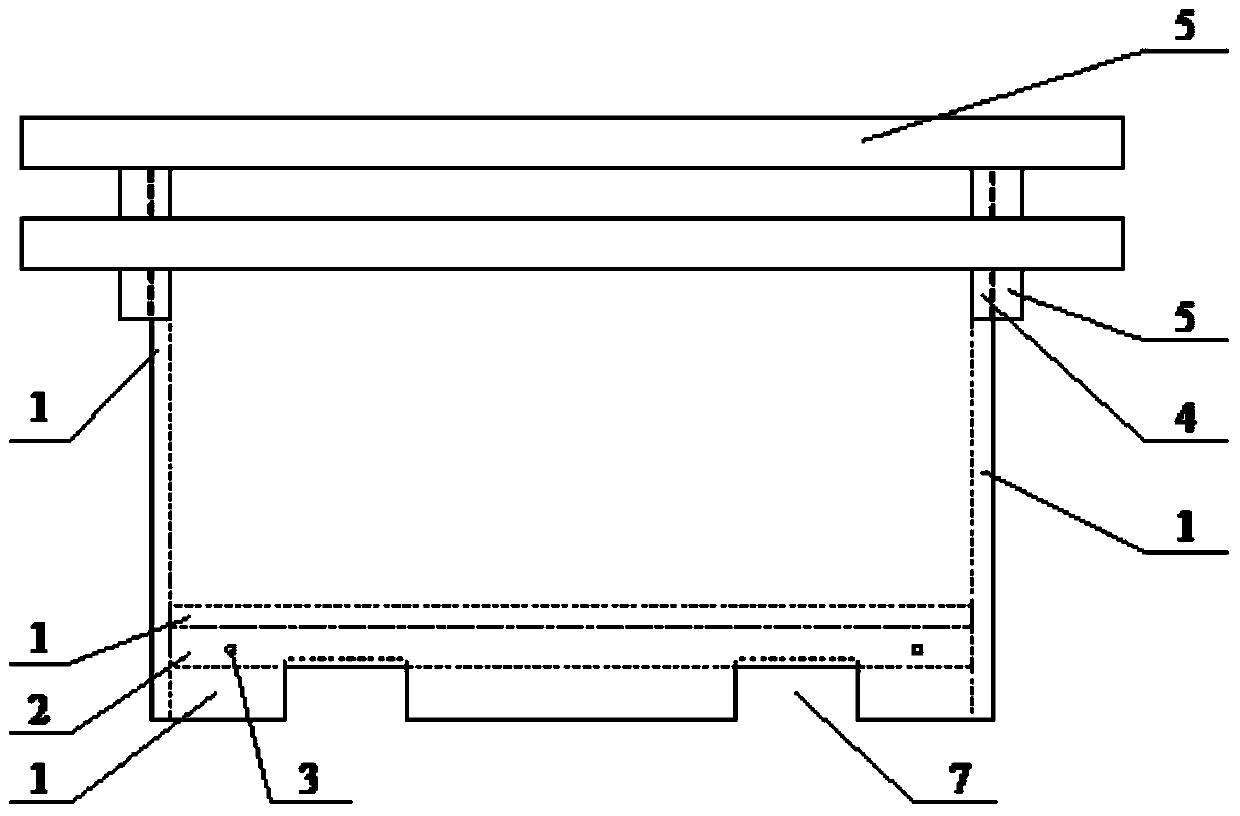

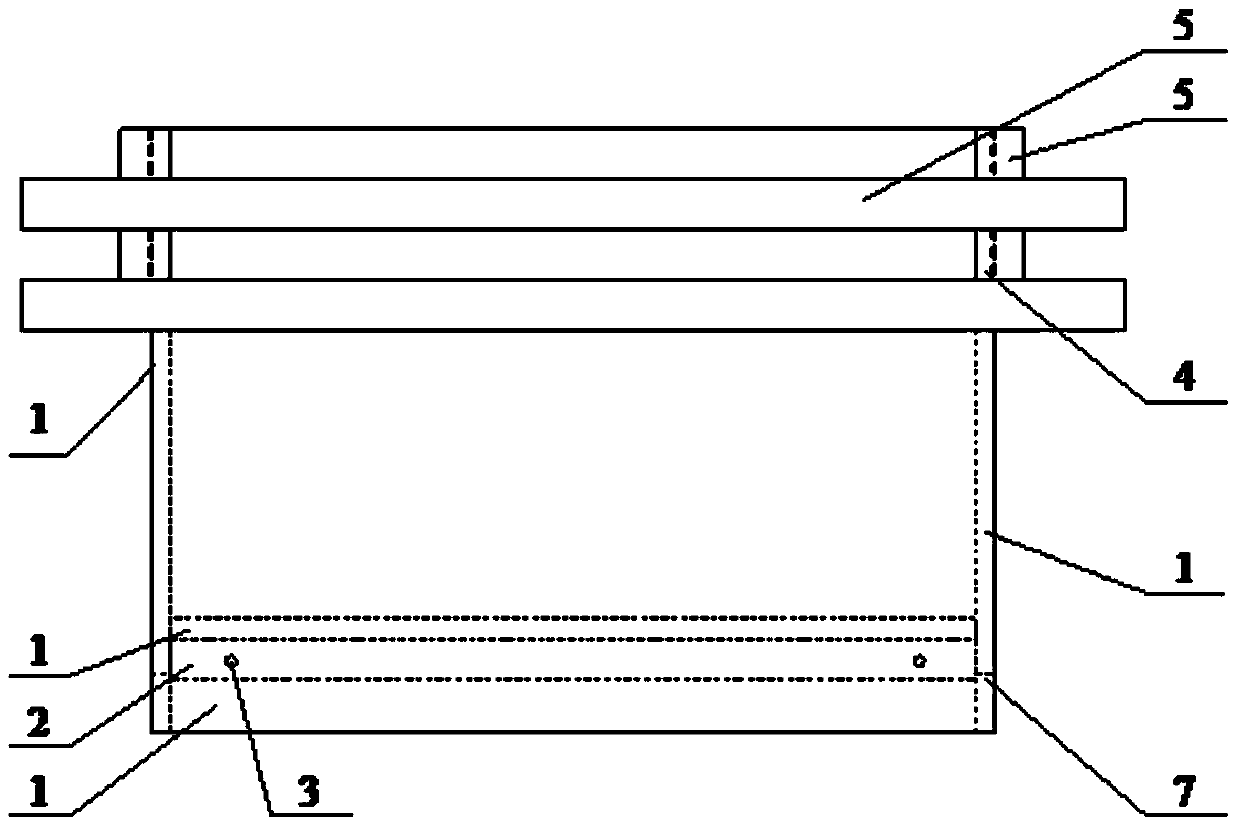

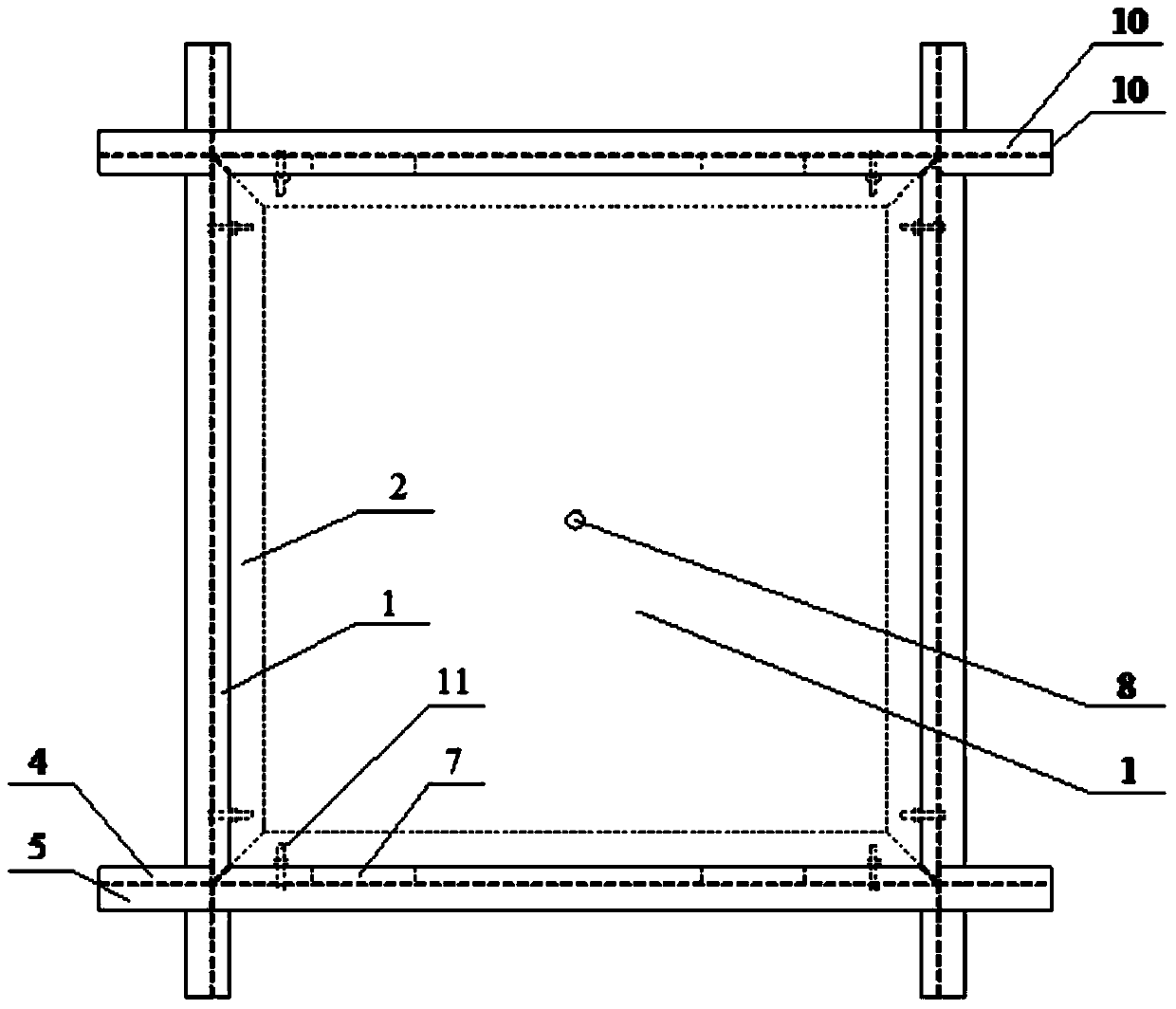

[0026] A stone edge flower pot, it comprises a stone plate 1, an angle steel frame 2, the angle steel frame 2 is arranged inside the stone plate 1, the said stone plate 1 comprises a plurality of side stone plates and a bottom surface stone plate, the angle steel frame 2 is connected with each side stone plate The lower end is fixed by screw 11.

[0027] The upper end of each side stone slab described in the above-mentioned scheme is bounded by many stone strips 5 bonding.

[0028] The protruding part of the stone strip 5 at the edge of the flower pot is fixedly connected with multiple compound stone strips 4 of the same width.

[0029] Two forklift holes 7 are provided at the lower ends of two opposite panels in the side slate.

[0030] The upper plane of the angle steel frame 2 supports the bottom surface slate of the flower pot, and the lower edge of the angle steel frame 2 is 55mm away from the side slate of the flower pot.

[0031] The stone edge flower pot includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com