Shock attenuation ventilation sole and shoe

A component and rubber technology, applied in the field of shock-absorbing and ventilating soles and shoes, can solve problems such as poor shock-absorbing and ventilating effects, and achieve the effect of improving the ventilation effect and enhancing the shock-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

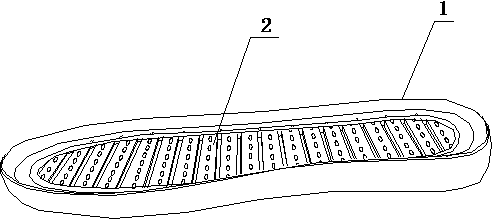

[0044] The present invention provides a shock-absorbing and ventilating shoe sole, comprising: a rubber outsole 1 and a shock-absorbing and ventilating element 2; refer to figure 1 , Figure 2-a and Figure 3-a shown, where figure 1 It is a structural diagram of a shock-absorbing and ventilating shoe sole of the present invention, Figure 2-a for figure 1 The structure diagram of the rubber outsole, Figure 3-a for figure 1 The structural diagram of the shock absorbing and ventilating components,

[0045] The inner bottom of the rubber outsole 1 is provided with an inner bottom groove matching the shock absorption and ventilation element 2, and the shock absorption and ventilation element 2 is placed in the inner bottom groove;

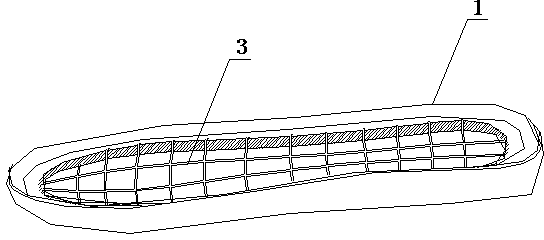

[0046] The surface of the inner bottom groove of the rubber outsole 1 is provided with a ventilation groove 3, referring to Figure 2-b shown, for figure 1 The plane structure diagram of the rubber outsole insole;

[0047] The surface of the ...

Embodiment 2

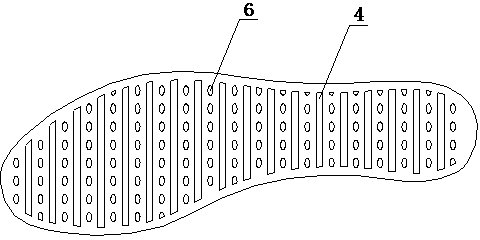

[0050] Embodiment 2 of the present invention provides a shock-absorbing and ventilating shoe sole, including the shock-absorbing and ventilating shoe sole as described in Embodiment 1, wherein the surface of the shock-absorbing and ventilating element 2 is provided with transverse grooves, refer to Figure 3-b and Figure 3-c shown, where Figure 3-b for figure 1 The front structure diagram of the shock absorbing and ventilating components, Figure 3-c for figure 1 The structure diagram of the reverse side of the shock-absorbing and ventilating components; specifically:

[0051] The front side of the shock-absorbing ventilation element 2 is provided with a front transverse groove 4, and the back side of the shock-absorbing ventilation element 2 is provided with a back side transverse groove 5, and the front side transverse groove 4 and the back side transverse groove 5 are spaced apart. set up;

[0052] The surface of the inner bottom groove of the rubber outsole 1 is pro...

Embodiment 3

[0055] Embodiment 3 of the present invention provides a shock-absorbing and ventilating sole, including the shock-absorbing and ventilating sole as described in Embodiment 1, wherein the shock-absorbing and ventilating element 2 further includes:

[0056] Ellipse points 6, said ellipse points 6 are arranged in a row on the plane between the front transverse grooves 4 of said shock-absorbing ventilation element.

[0057] Small elliptical cylinders 7, said small elliptical cylinders 7 are arranged in a row on the surface of the reverse transverse groove 5 of said shock-absorbing ventilation element.

[0058]In this embodiment, a number of small elliptical columns are provided in the reverse groove of the shock-absorbing and ventilating element, which can prevent the shock-absorbing and ventilating element from collapsing when stressed, improve the force-bearing capacity of the shock-absorbing element, and enhance shock absorption. effect, preventing blockage of the ventilation g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com