Electrode screen board for radial-flow electric dust collector

A technology of electrostatic precipitator and electrode net, applied in the direction of electrode structure, electrostatic separation, etc., which can solve the problems of large air flow rate and difficulty in meeting the design requirements for the dust removal effect of run-of-the-river electrostatic precipitators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

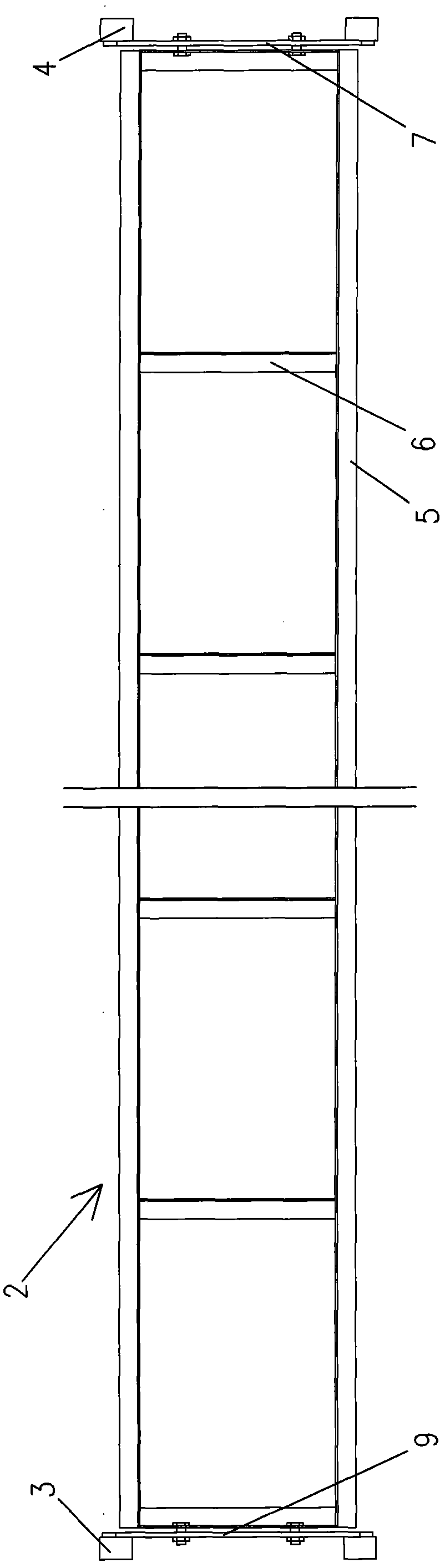

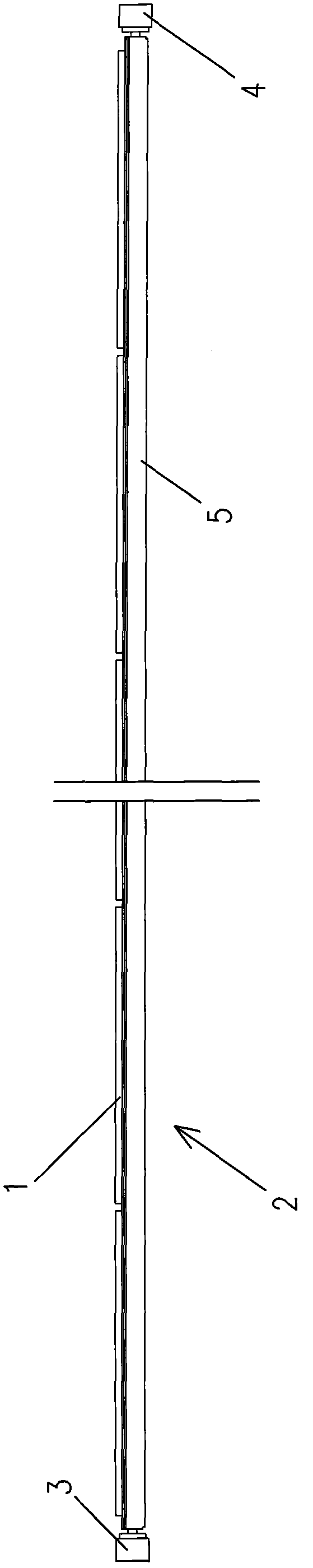

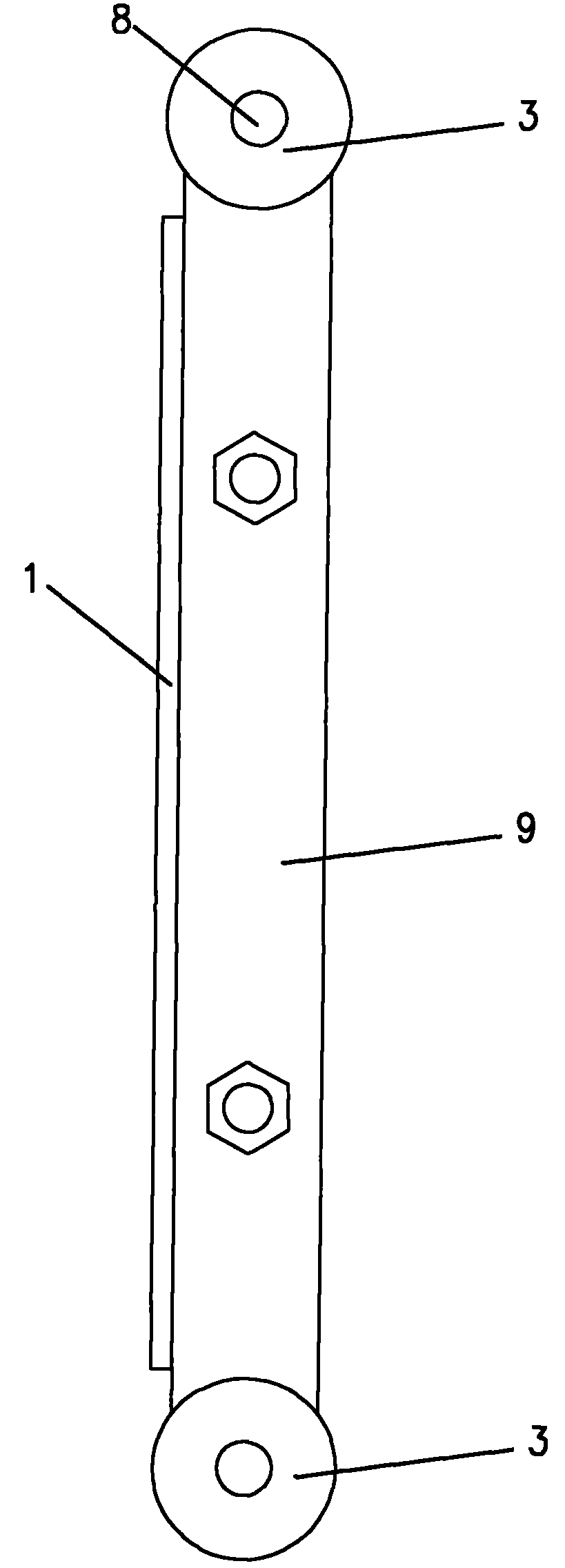

[0020] Such as figure 1 , figure 2 with image 3 As shown, the electrode grid plate for the radial electrostatic precipitator of the present invention includes a plurality of porous metal foam plates whose plates are located in the left and right vertical directions. The front surfaces of the electrode plates are flush with each other, and a plurality of porous metal foam plates are spliced into an electrode plate 1 whose surface can pass through the airflow, that is, the airflow can pass through the plate surface of the electrode plate 1, and the rear of the electrode plate 1 is provided with a mounting frame 2, and the electrode plate 1 is fixed on the installation frame 2;

[0021] The bulk density of the above-mentioned porous metal foam plate is 0.15-2g / cm 3 , the specific surface area of the porous metal foam plate is 7.8×10 2 -1.5×10 8 m 2 / m 3 , the thickness of the porous foam metal plate is 3-60mm, and the number of holes per inch (PPI) on the porous foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com