Feeding and press fitting device of clamp spring of clutch booster and press fitting method of clamp spring of clutch booster

A technology of pressing device and booster, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and difficult pressing of the circlip, and achieve the effects of high efficiency, easy efficiency, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

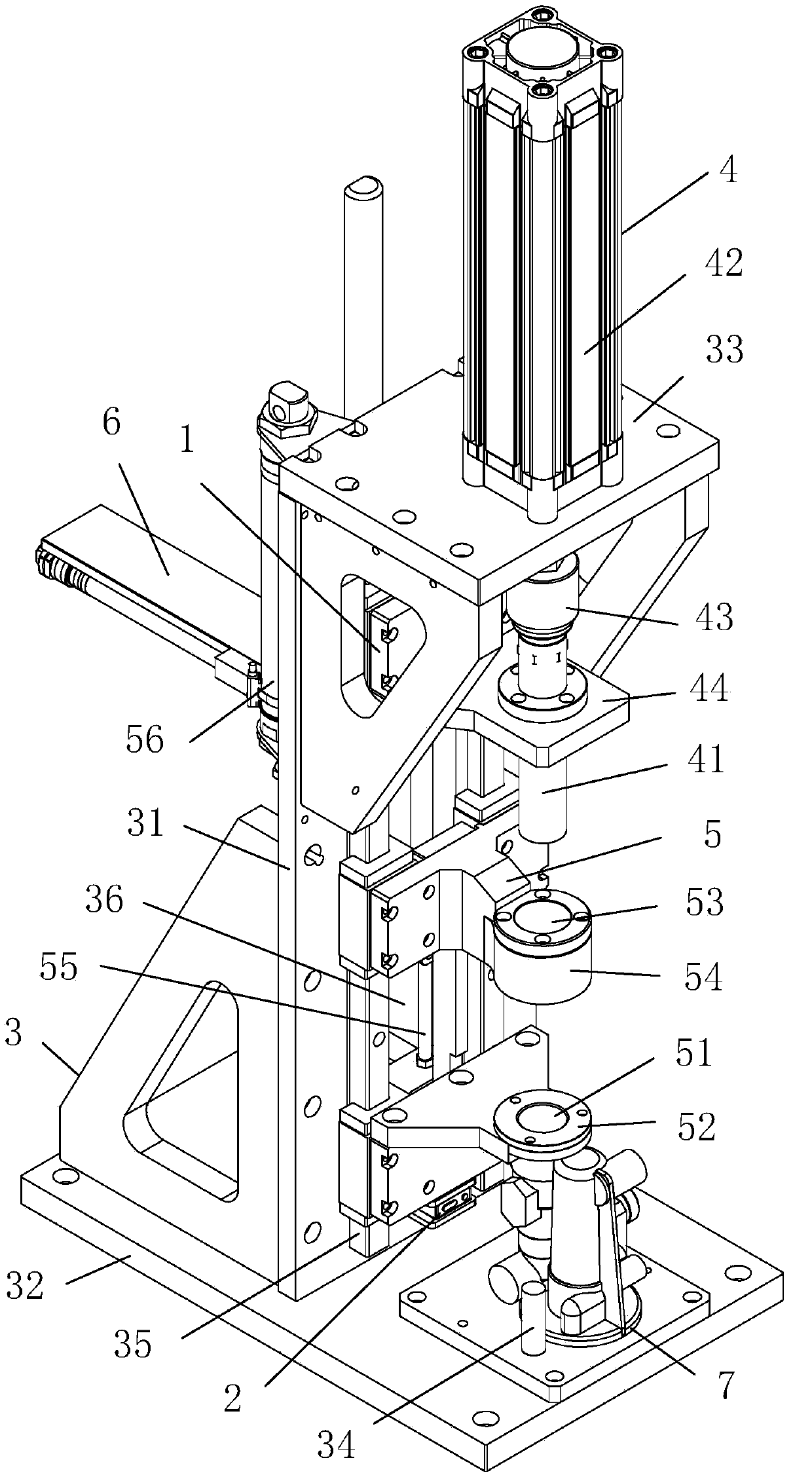

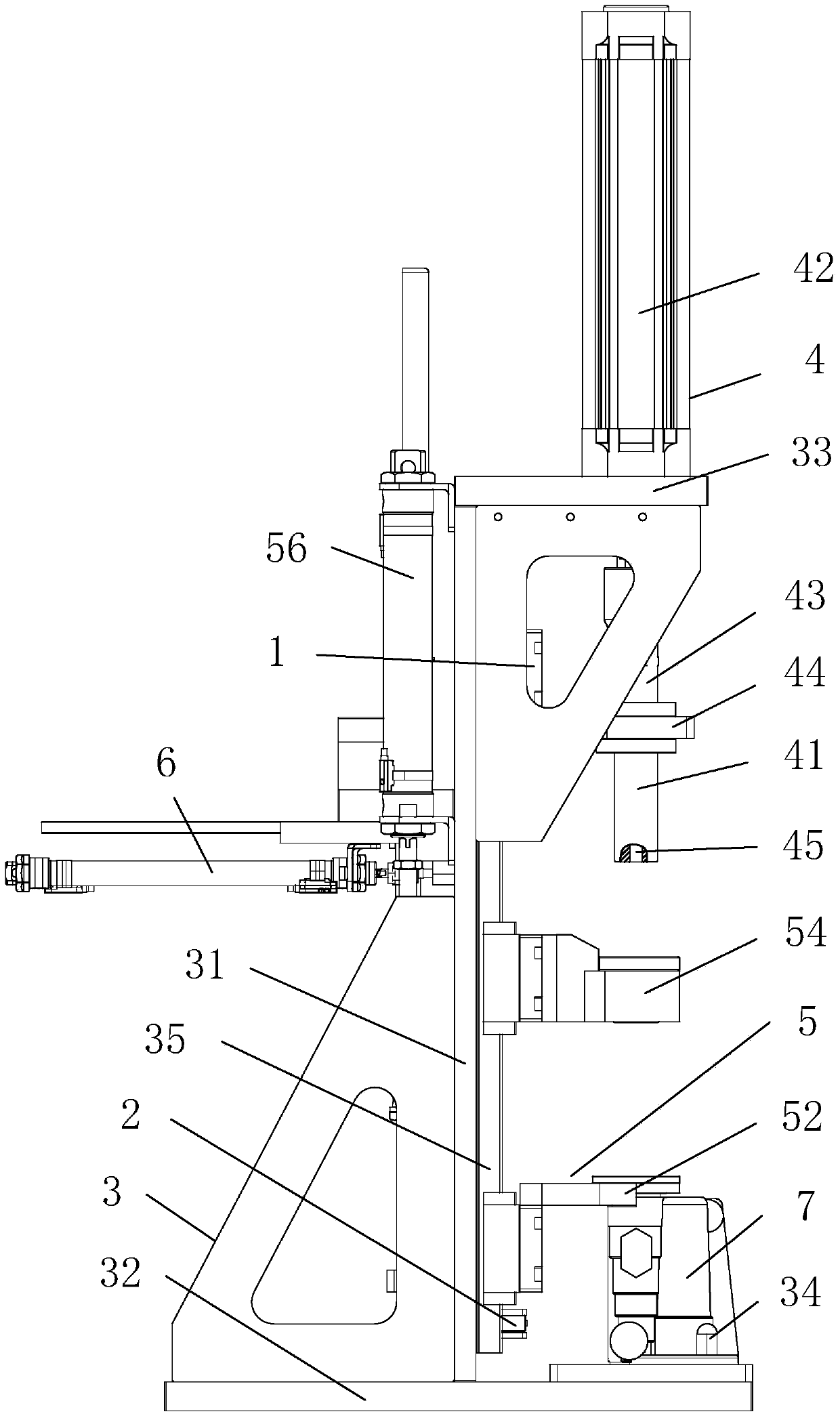

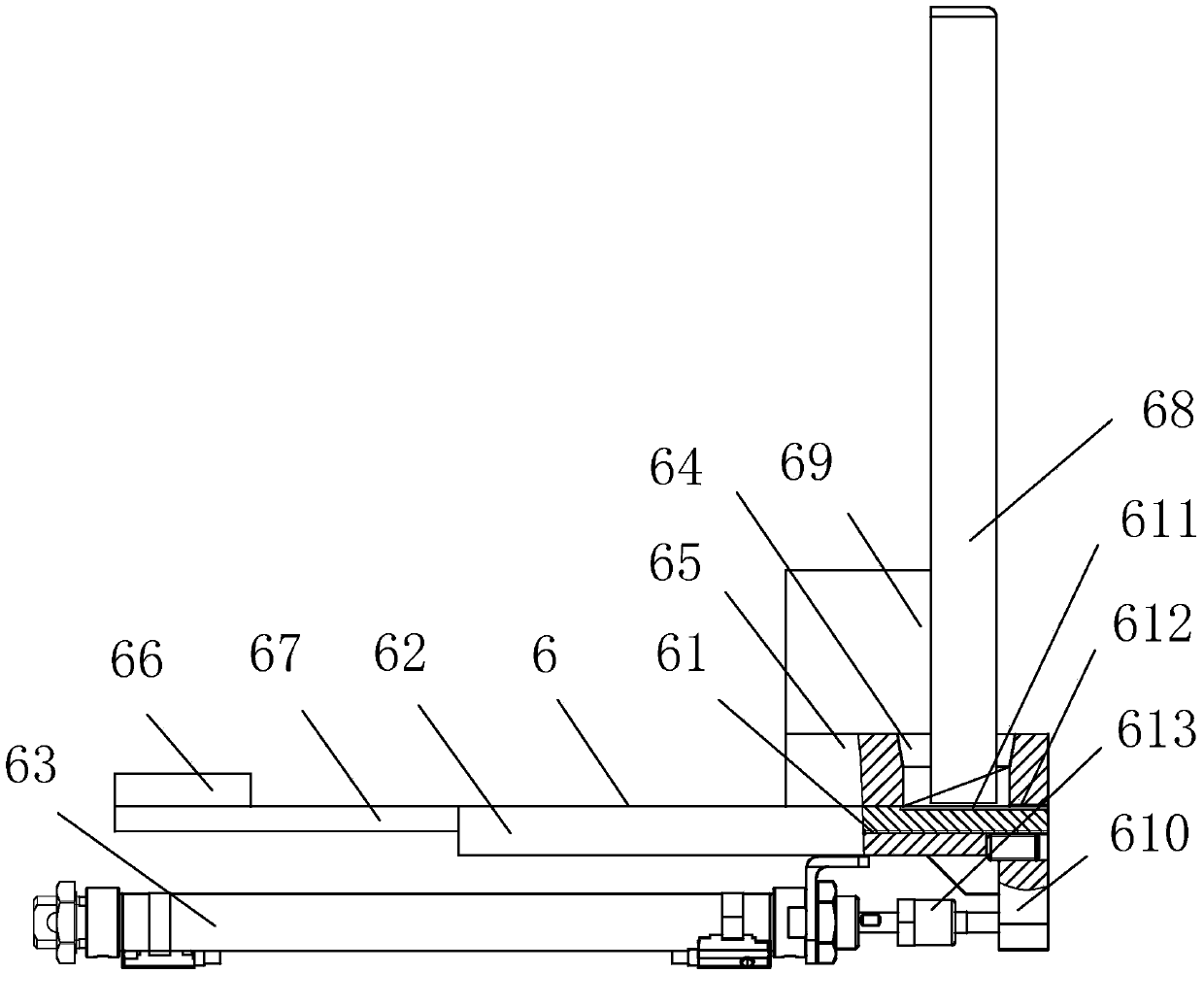

[0022] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a clutch booster circlip feeding and pressing device, including a base 3 with a positioning assembly, a controller 1, a pressing mechanism 4 with a pressure head 41 opposite to the positioning assembly, a positioning assembly and a pressing mechanism 4 between the preloading guide mechanism 5 and the feeding mechanism 6 that the jump spring is sent to the lower side of the pressure head 41.

[0023] The base 3 includes a riser 31, a bottom plate 32 welded to the lower end of the riser 31 and a top plate 33 welded to the upper end of the riser 31; The positioning column (not shown in the figure) and the positioning nail 34 positioned at the outside of the positioning column; the front side of the riser 31 has two vertical slide rails 35. The vertical plate 31 has a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com