A magnetic grinding and polishing method and device for the inner surface of a thick-walled ceramic tube

A magnetic grinding and ceramic tube technology, applied in the field of magnetic grinding and polishing methods and devices for the inner surface of thick-walled ceramic tubes, can solve the problems of processing accuracy, surface processing quality, workpiece performance, ceramic tube inner surface polishing, poor surface polishing uniformity, etc. Achieve the effect of improving grinding efficiency, low manufacturing cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with reference to the accompanying drawings.

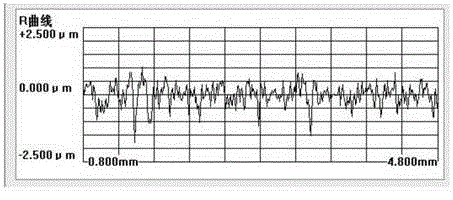

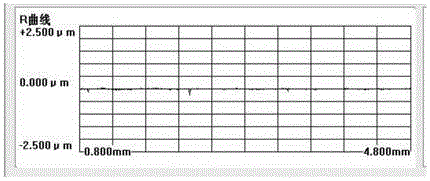

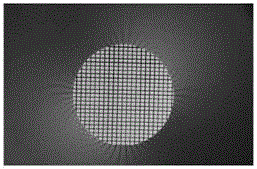

[0025] like figure 1 , figure 2 As shown, a method for grinding and polishing the inner surface of a thick-walled ceramic tube comprises the following steps:

[0026] a. Clamp the thick-walled ceramic tube 7 on the three-jaw chuck 8 of the grinding and polishing device for the inner surface of the thick-walled ceramic tube, and use a concentricity measuring instrument to ensure the eccentricity with the rotating shaft;

[0027] b. Place two permanent magnets 5 with a size of 45*45*20 on both ends of the pole frame 6 with N-S or S-N magnetic poles, and the two permanent magnets 5 attract each other to form a magnetic circuit with respect to the magnetic poles. Simultaneously adjust the distance between the magnetic pole frame 6 and the thick-walled ceramic tube 7 so that the two permanent magnets 5 and the outside of the thick-walled ceramic tube 7 maintain a 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com