A kind of ultra-precision grinding head device

A grinding head and ultra-precision technology, applied in grinding devices, grinding machine tools, grinding tools, etc., can solve the problem of difficult to replace magnetic fluid effectively, and achieve the effect of easy industrialization, better grinding effect and small surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

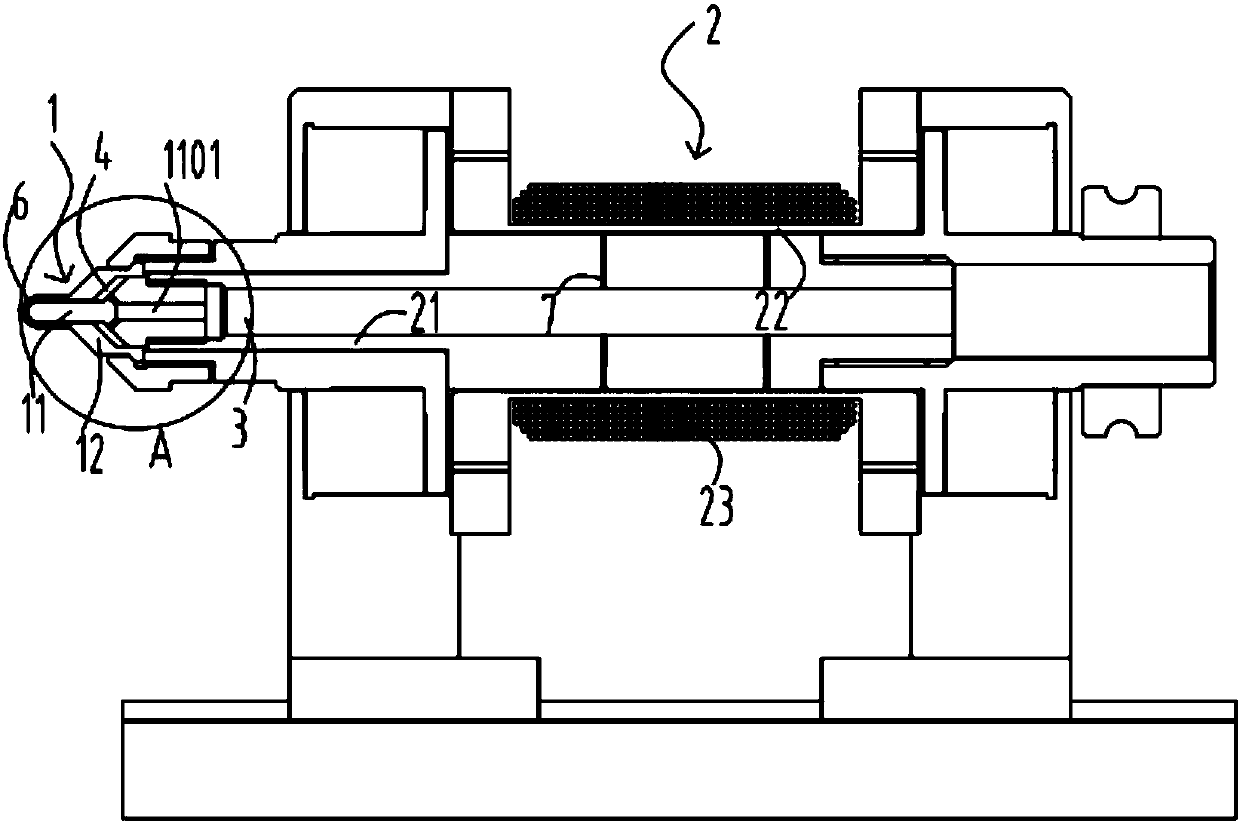

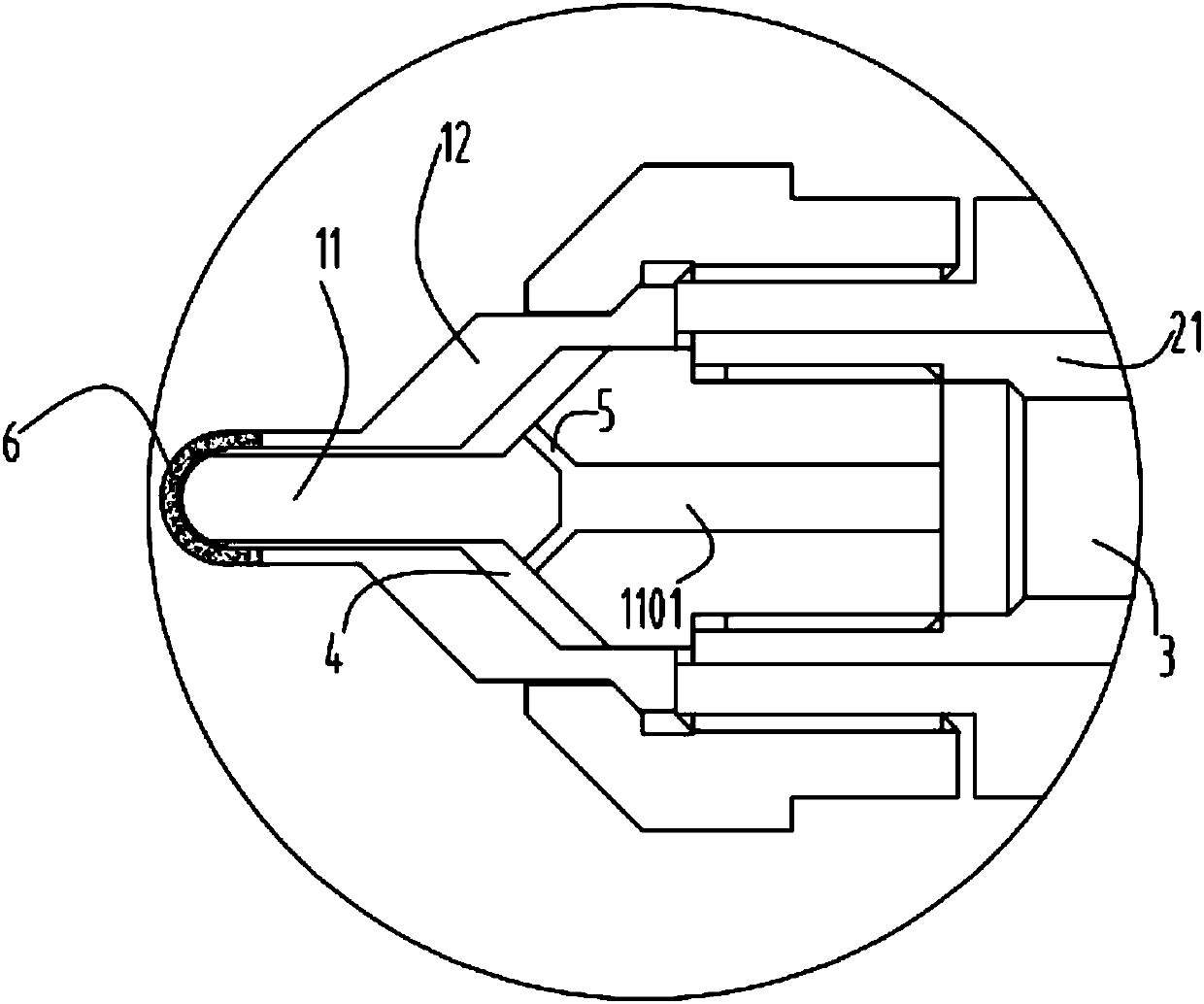

[0025] figure 1 It is a schematic diagram of the ultra-precision grinding head device, figure 2 for figure 1 The partial enlarged schematic diagram of A. Such as figure 1 , figure 2As shown, an ultra-precision grinding head device includes a grinding head 1 and an excitation device 2, the grinding head 1 is connected to the excitation device 2, and the excitation device 2 drives the rotation of the grinding head 1 and transmits the magnetism to the grinding head 1; the inside of the excitation device 2 A gas channel 3 is provided, and the gas channel 3 communicates with the grinding head 1, and the air flow in the gas channel 3 is ejected from the outer surface of the grinding head 1 through the grinding head 1; the grinding head 1 includes a magnetic core grinding head 11 and an air hole grinding head 12. The front end of the magnetic core grinding head 11 is located in the air hole grinding head 12, a gap 4 is formed between the front end of the magnetic core grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com