A magnetic-gas composite fluid grinding head device

A magnetic-gas composite and grinding head technology, which is applied in the direction of grinding machines, optical surface grinding machines, grinding/polishing equipment, etc., can solve the problem that the magnetic fluid is difficult to replace effectively, and achieve easy industrial implementation, improve processing efficiency, improve utilization rate and The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

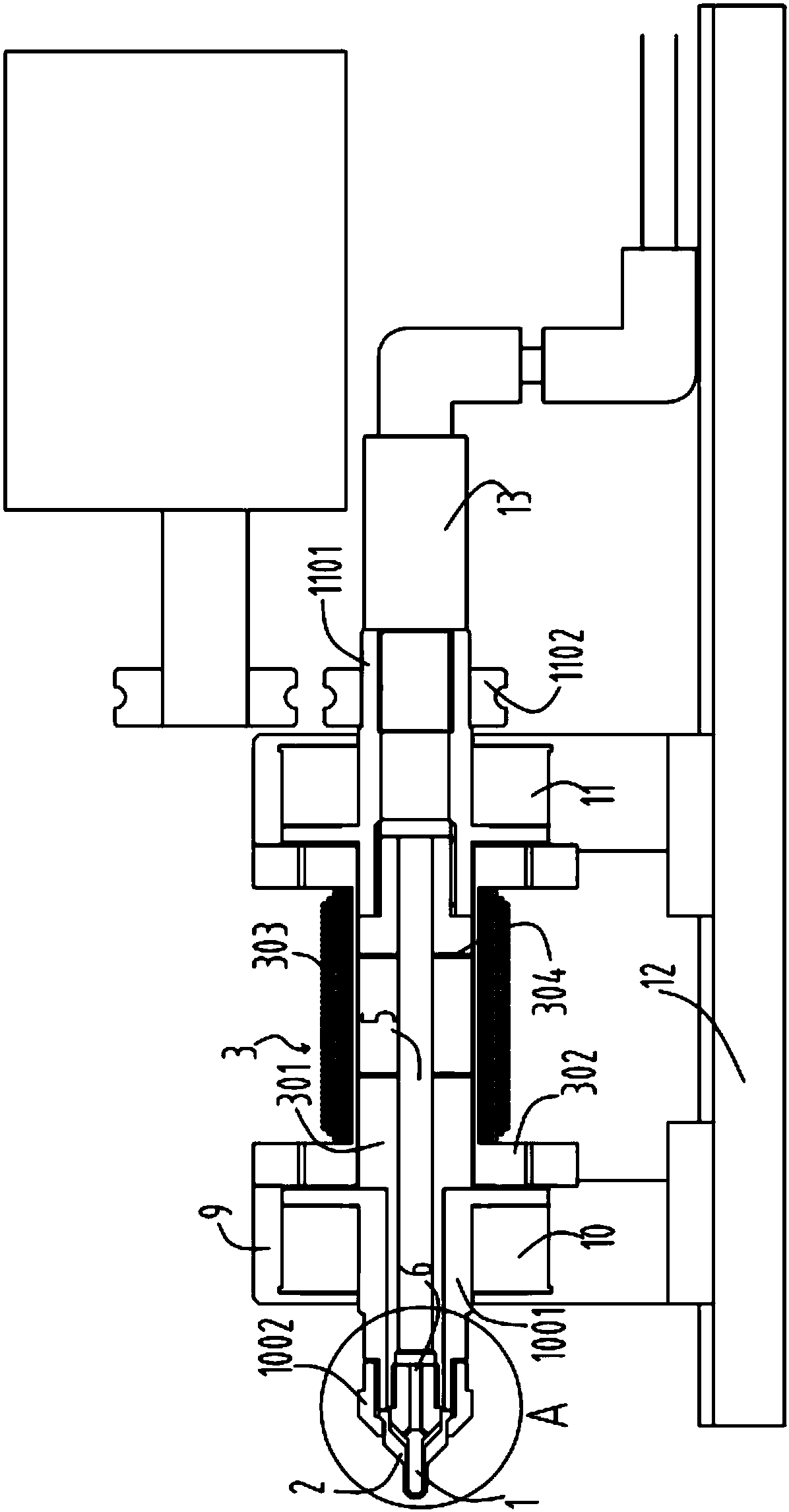

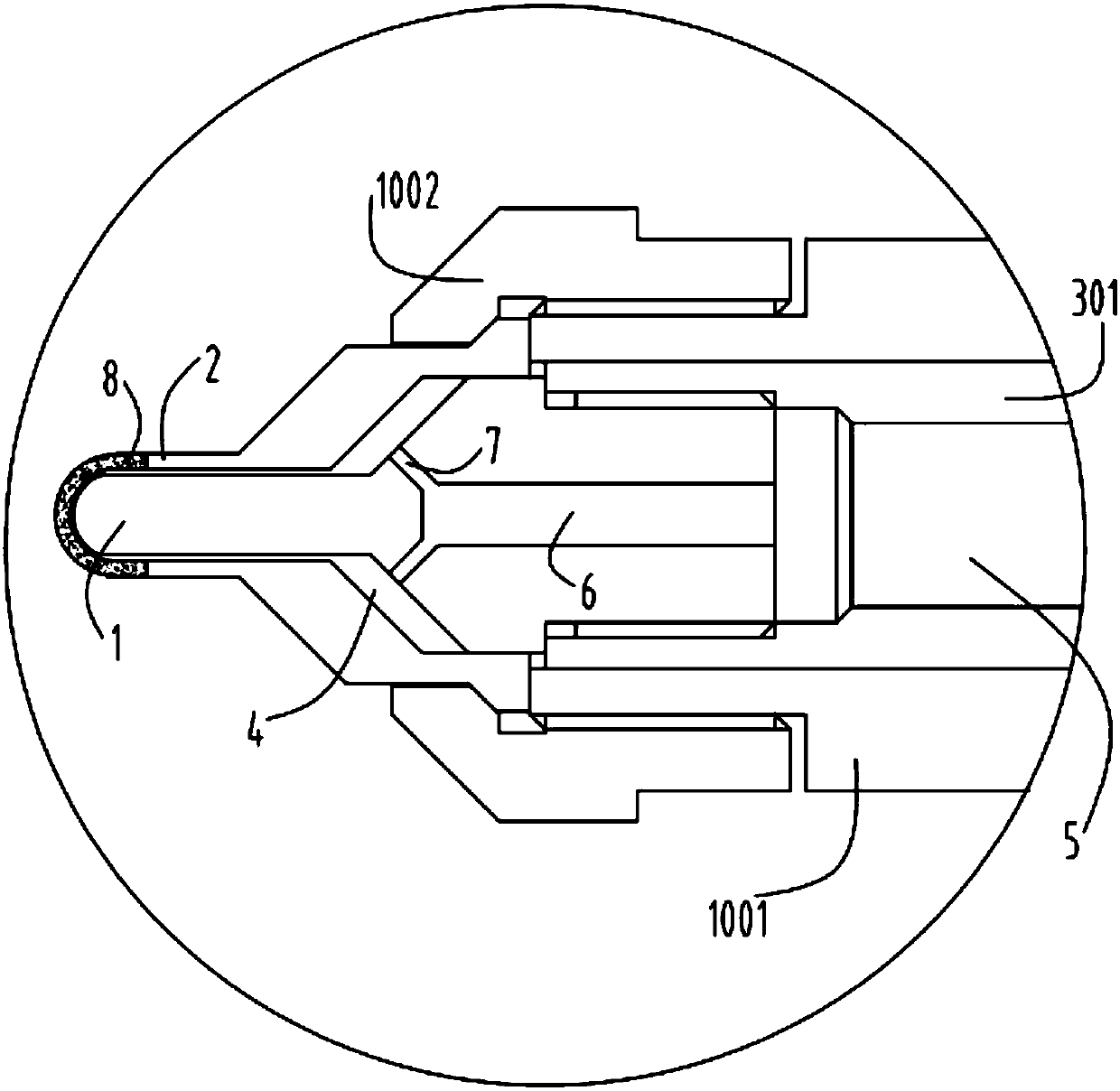

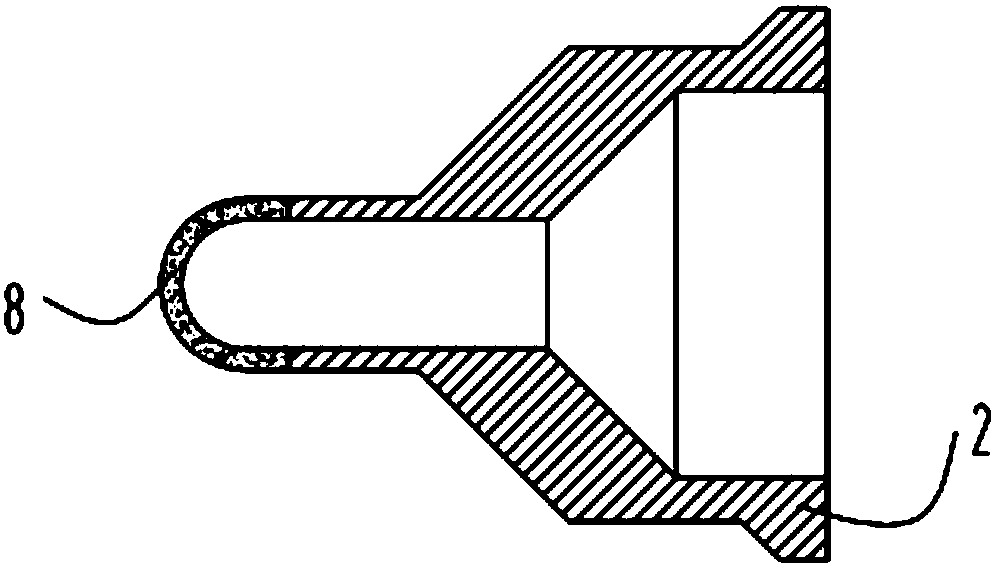

[0033] figure 1 It is a schematic diagram of the magnetic-gas composite fluid grinding head device, figure 2 forfigure 1 Partial enlarged schematic diagram of A, image 3 An enlarged schematic diagram of the air hole grinding head, Figure 4 An enlarged schematic diagram of the magnetic core grinding head, Figure 5 An enlarged schematic diagram of the electromagnet mandrel, Figure 6 Enlarged schematic diagram for bearing positioning sleeve A, Figure 7 Enlarged schematic diagram for bearing positioning sleeve B, Figure 8 Enlarged schematic diagram for the coil insulation sleeve, Figure 9 Zoom in on the schematic for the threaded retainer. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a magnetic-gas composite fluid grinding head device includes a magnetic core grinding head 1, an air hole grinding head 2 and an excitation device 3. The front end of the magnetic core grinding head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com