Automobile five-connecting-rod rear axle assembly split charging clamp

A five-link, rear axle technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., to ensure assembly quality, improve product performance and assembly quality, and assembly operations are simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail in conjunction with accompanying drawing now.

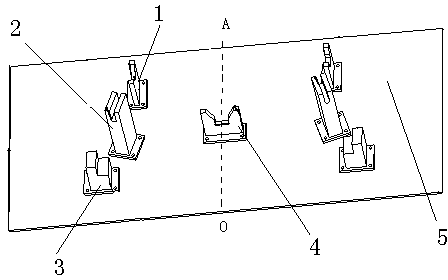

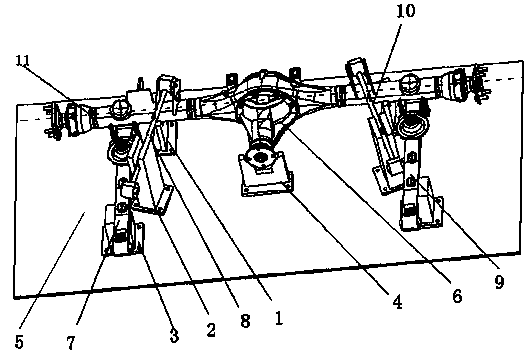

[0014] Such as figure 1 The automobile five-link rear axle assembly fixture shown includes a base 5 on which two first V-shaped blocks 1, two U-shaped blocks 2, two L-shaped blocks 3 and a second Two V-shaped blocks 4, two U-shaped blocks 2 are located on both sides of the second V-shaped block 4, two first V-shaped blocks 1 are respectively located behind the two U-shaped blocks 2, and two L-shaped blocks 3 are respectively Located in front of the two U-shaped blocks 2, and the two first V-shaped blocks 1, two U-shaped blocks 2 and two L-shaped blocks 3 are respectively relative to the central axis 0A of the V-shaped groove of the second V-shaped block 4 Symmetrical arrangement, the relative position among the first V-shaped block 1, U-shaped block 2, L-shaped block 3 and the second V-shaped block 4, the height of the first and second V-shaped block 4 and the depth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com