Autoclaved curing kettle

A technology of autoclave curing and curing kettle, which is applied in the field of curing reaction kettle, which can solve the problems of brick body strengthening, little effect, and unsatisfactory drying effect, etc., and achieve the effect of not easy to crack and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

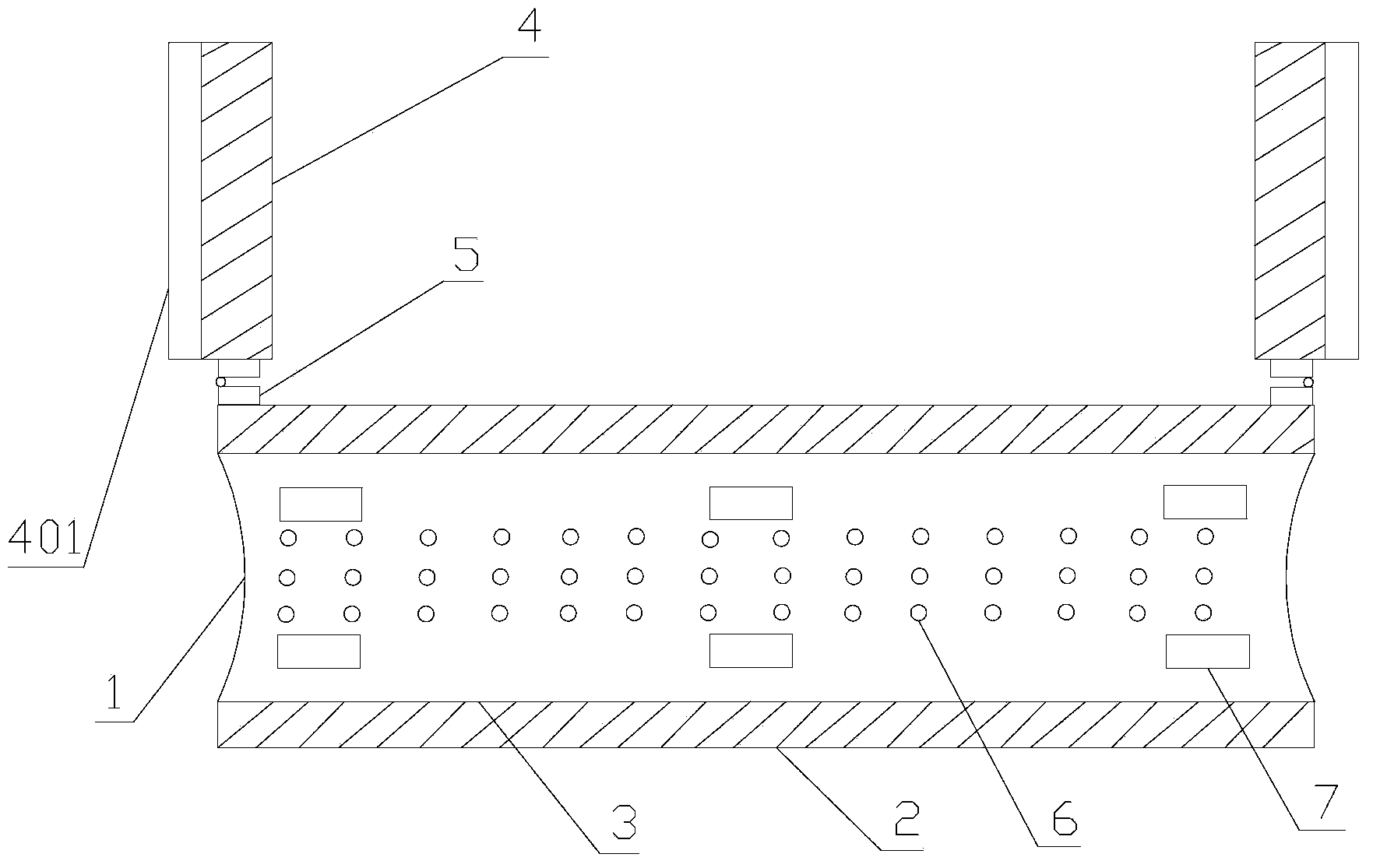

[0016] Such as figure 1 As shown, an autoclaved curing kettle includes a curing kettle body 1, an outer kettle wall 2, an inner kettle wall 3, a steam port 6, a suction port 7, a kettle lid 4, a kettle lid seal 401 and a kettle lid hinge 5. It is characterized in that the main body 1 of the curing kettle is formed by connecting the outer kettle wall 2 and the inner kettle wall 3, the inner kettle wall 3 is provided with several steam ports 6 and air suction ports 7, and the kettle cover 4 is arranged on the top of the curing kettle main body 1 , the kettle lid 4 is connected to the curing kettle body 1 by the kettle lid hinge 5 , and a kettle lid seal 401 is provided on one side of the kettle lid 4 .

[0017] Working principle: In the first stage, the air in the autoclave is removed. This is to increase the heat release coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com