Thin ventilation skylight

A ventilation skylight and thin technology, applied in the direction of skylight/dome, roof, building components, etc., can solve the problems of no load capacity, rain and snow of the product, large building load and cost, etc., to reduce the production labor level and reduce the manufacturing cost. The effect of process difficulty and load capacity saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

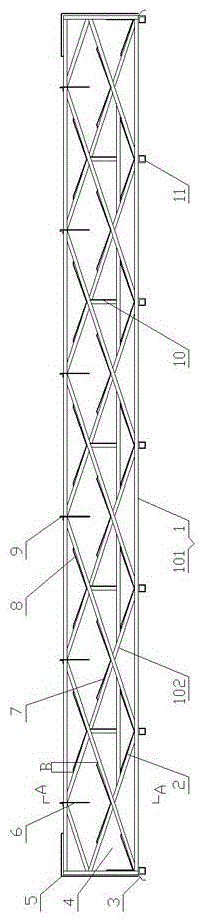

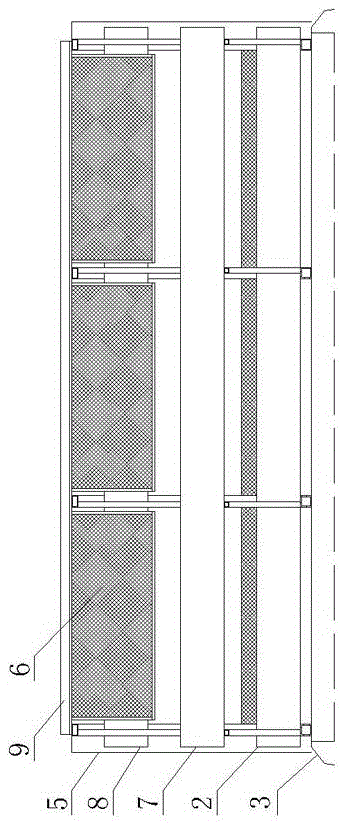

[0022] As shown in the figure, the thin ventilation skylight includes multiple rows of parallel structural trusses 1 arranged on the roof vents, the structural trusses 1 are arranged longitudinally along the roof vents, and each row of structural trusses 1 is composed of a rectangular frame 101 and a The rectangular frame 101 is composed of a plurality of ventilation units 102 connected by profiles. The upper ends of multiple rows of structural trusses 1 are connected to each other through vertical rods 9 evenly distributed above each ventilation unit 102 , and each row of structural trusses 1 is connected by bolts to facilitate manufacturing and installation. Multiple ventilation units 102 of each row of structural trusses 1 form an upper, middle and lower triple V-shaped overlapping structure through their own profiles. Between several columns of ventilation units 102 opposite to each other on the multi-row structural truss 1, there are three layers of V-shaped weather shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com