Soft phyllite tunnel excavation deformation control method

A tunnel excavation and deformation control technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as increasing project costs, threatening construction safety, and difficult deformation, so as to save materials, speed up construction progress, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

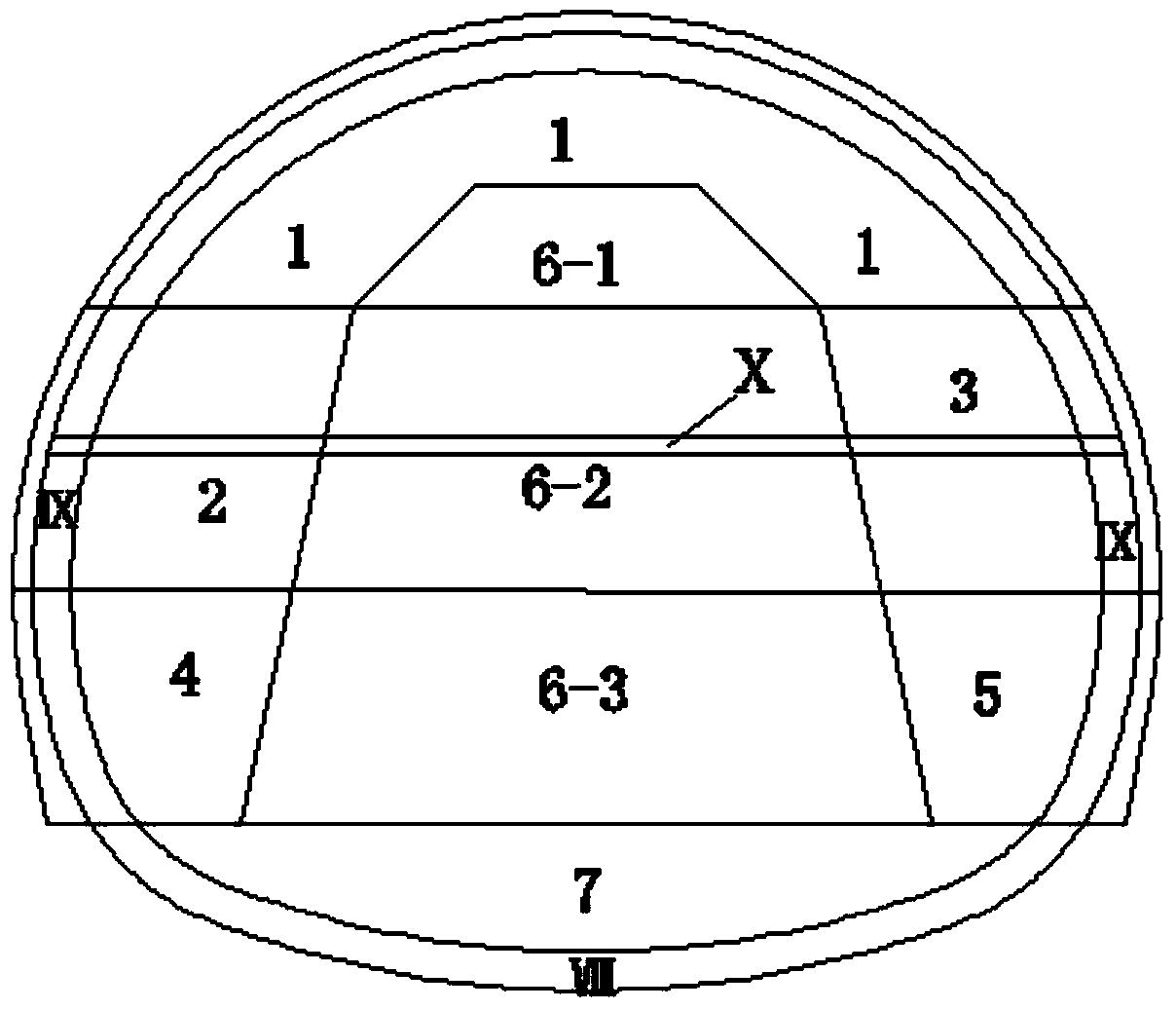

[0018] Such as figure 1 As shown, the excavation method of the weak phyllite tunnel includes the following steps:

[0019] (1) Use the vertical steel frame of the upper circulation frame for advanced support.

[0020] (2) Adopt mechanical cooperation with manual or weak blasting to excavate one step up step by step, and at the same time, every time it is looped, the face of the tunnel is sprayed with 5cm thick concrete to seal.

[0021] (3) Implement initial support around the first part of the upper step.

[0022] (4) Excavate 2 steps at the rear of the upper step, and then spray 5cm thick concrete to seal the face of the tunnel for initial support.

[0023] (5) Excavate 3 parts of the middle step after lagging behind 2 parts of the middle step, and then spray 5cm thick concrete to seal the face of the tunnel, and do the initial support. At the same time, after the initial support is completed on the left and right sides 2, 3 of the middle step, a horizontal support is erected at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com