CRD middle partition wall reserving and water sealing flange welding construction technology

A technology of water-stop flange and construction technology, which is applied to shaft equipment, shaft lining, mining equipment, etc. It can solve the problems of complicated procedures, large ground and pipeline settlement, etc., so as to speed up the construction progress, ensure construction safety, and avoid ground and The effects of pipeline settlement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

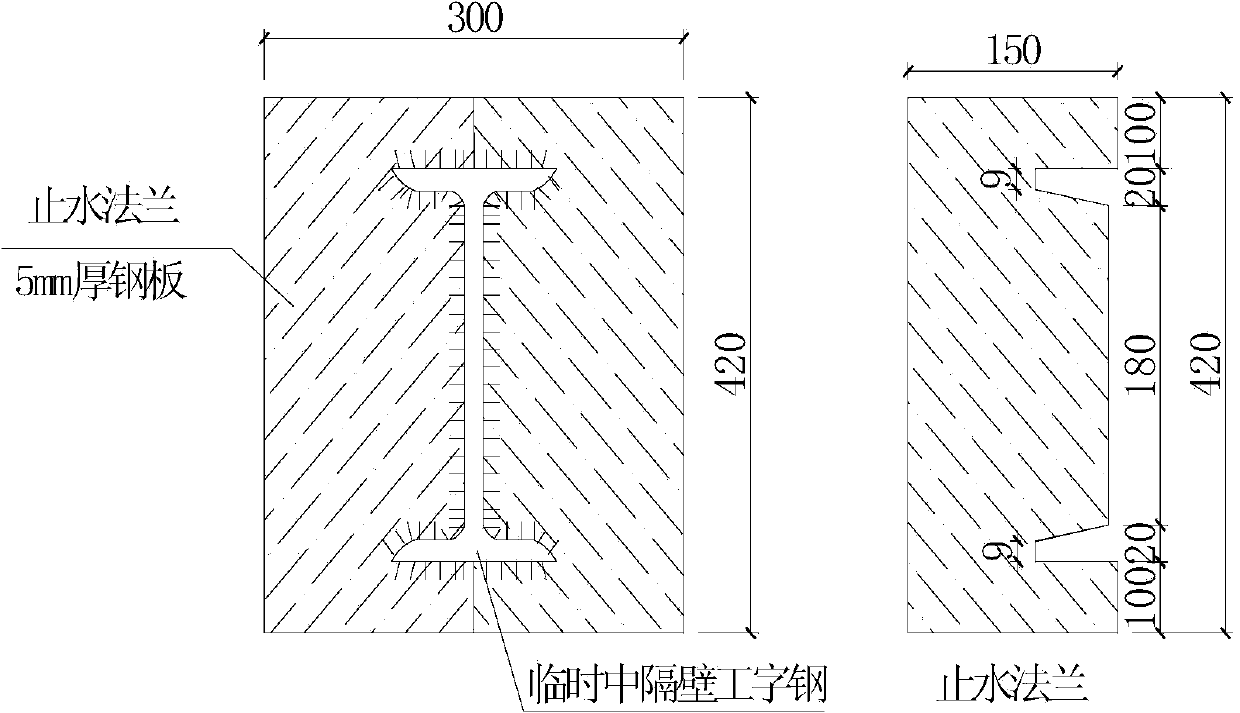

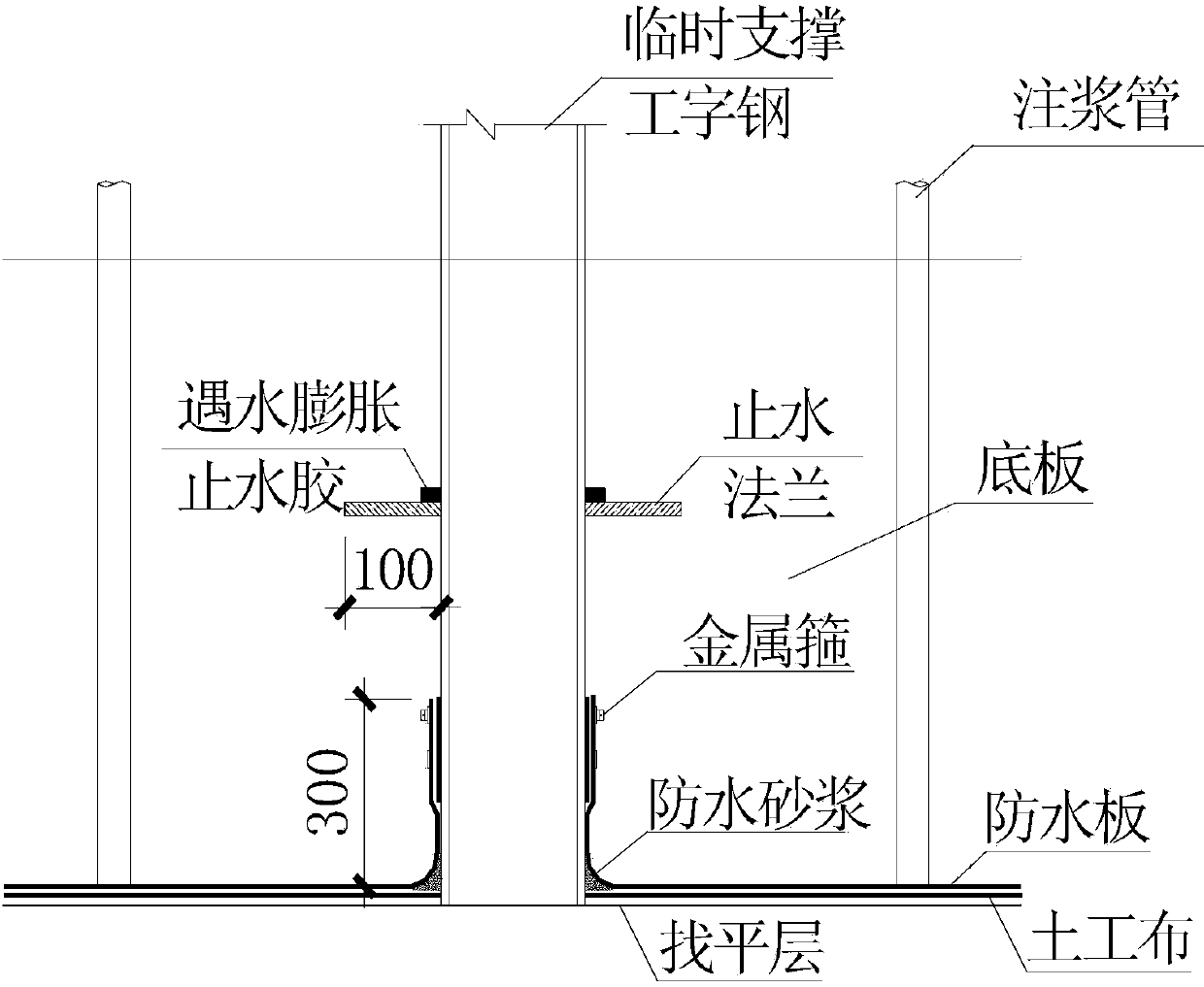

[0019] During the construction of the second lining, the I-beam on the middle partition of the underground excavation tunnel is temporarily reserved, and the water-stop flange is welded within the range of the second lining on the top and bottom of the I-steel, and the waterproof board is laid along the "L" shape of the middle partition, and metal steel hoops and water-resistant Expansive water-stop glue strengthens the construction process of waterproofing.

[0020] The welded water-stop flange within the second lining range of the I-beam top and bottom of the temporary middle partition is that the temporary middle partition within the second lining range is welded with a 5mm steel plate as the water-stop flange, and the size of the water-stop flange steel plate is 420×300mm, divided into two parts. A piece of steel plate is processed and butted, and then welded tightly with the I-beam. After the welding of the water-stop flange is completed, apply 2cm wide and 1cm thick wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com