On-line self-cleaning heat exchange enhancement solar sewage source heat pump system

A sewage source heat pump and enhanced heat transfer technology, which is applied in the field of solar sewage source heat pump systems, can solve problems such as difficult start-up, dirt growth, and low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

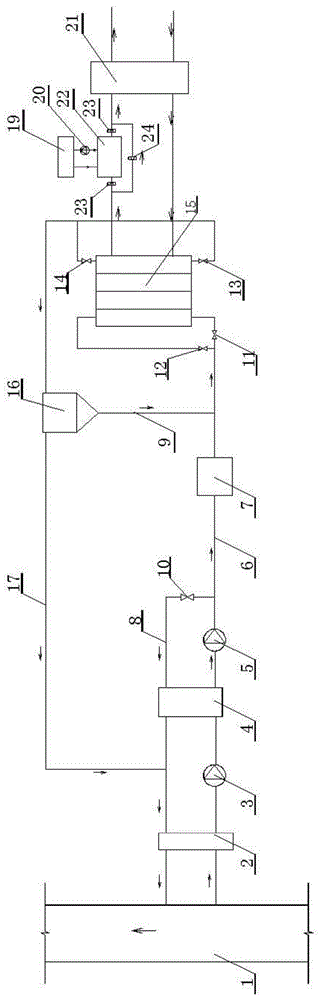

[0015] Such as figure 1 As shown, the sewage in the main sewage canal 1 first passes through the mechanical grille 2 to remove large-scale dirt (the size of which is greater than 5mm), and is pumped into the automatic decontamination device 4 by the first-stage pump 3, and further removes the dirt (the size of which is greater than 5mm) size 3-5mm); the filtered sewage is extracted by the secondary pump 5, which is divided into two parts, one part enters the automatic decontamination device 4 through the backwash pipeline 8 to backwash the decontamination filter surface, and will adhere to the filter The dirt and sundries on the surface are washed away, and the control valve 10 installed on the backwash pipeline 8 adjusts the parameters such as the water volume and water pressure of the backwash; the other part enters the hair filter 7 to remove the hair-like dirt and sundries in the sewage , the filtered sewage and the solid particles separated from the solid-liquid separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com