Solar sewage-source heat pump system capable of carrying out on-line cleaning and automatic decontamination

A sewage source heat pump and solar energy technology, which is applied to heat pumps, lighting and heating equipment, fluid circulation arrangements, etc., can solve problems such as difficulty in starting up, blockage of heat exchange tubes, and low heat exchange efficiency, so as to improve the heat exchange performance of the system and improve Inlet water temperature, the effect of avoiding clogging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

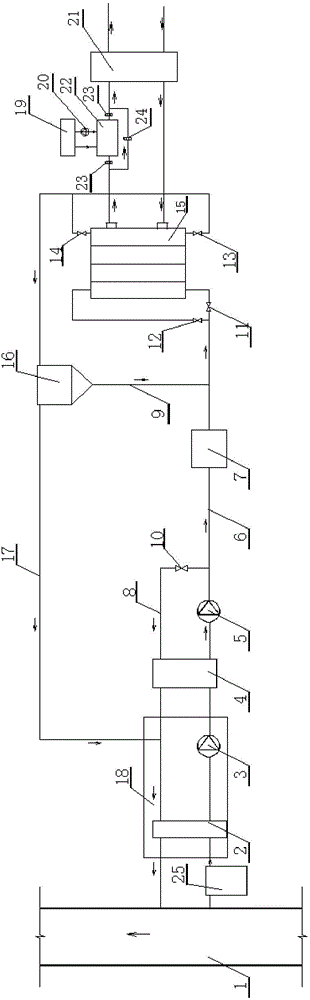

[0013] The sewage in the main sewage canal 1 enters the grit chamber 25, and sand, sludge and other sundries are pumped back to the downstream of the main sewage canal 1 by the sludge pump in the grit chamber 25, and the sewage enters the mechanical grille 2 of the water intake pond 18, and the mechanical grid The grid 2 filters part of the dirt and debris, and the filtered sewage is pumped into the automatic decontamination device 4 by the primary pump 3 to further remove the dirt and debris; the filtered sewage is extracted by the secondary pump 5, which is divided into two Part, one part enters the automatic decontamination device 4; the other part enters the hair filter 7 through the heat exchanger inlet line 6, and the hair and other sundries are filtered out, and the filtered sewage and the solid particles separated from the solid-liquid separator 16 Together enter the sewage heat exchanger 15 to participate in heat exchange, the outlet of the sewage heat exchanger 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com