Method for monitoring OPGW online with the use of optical fiber sensing technology

An optical fiber sensing technology, optical fiber technology, applied in the direction of using optical devices, measuring devices, measuring heat, etc., can solve the problems of few measurement points, inability to realize effective location of accident points, and inability to make full use of them, so as to ensure long-term performance Effect

Inactive Publication Date: 2014-03-12

YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the point-splitting fiber grating sensor has few measurement points and cannot effectively locate the accident point

Moreover, this monitoring method cannot make full use of the advantages of the OPGW embedded optical fiber

Although the Brillouin scattering sensing technology can make full use of the optical fiber in the OPGW and realize the dual-parameter measurement of temperature and strain, this monitoring method currently has the problem of cross-sensitivity of temperature and strain, which greatly limits its practical application. limit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

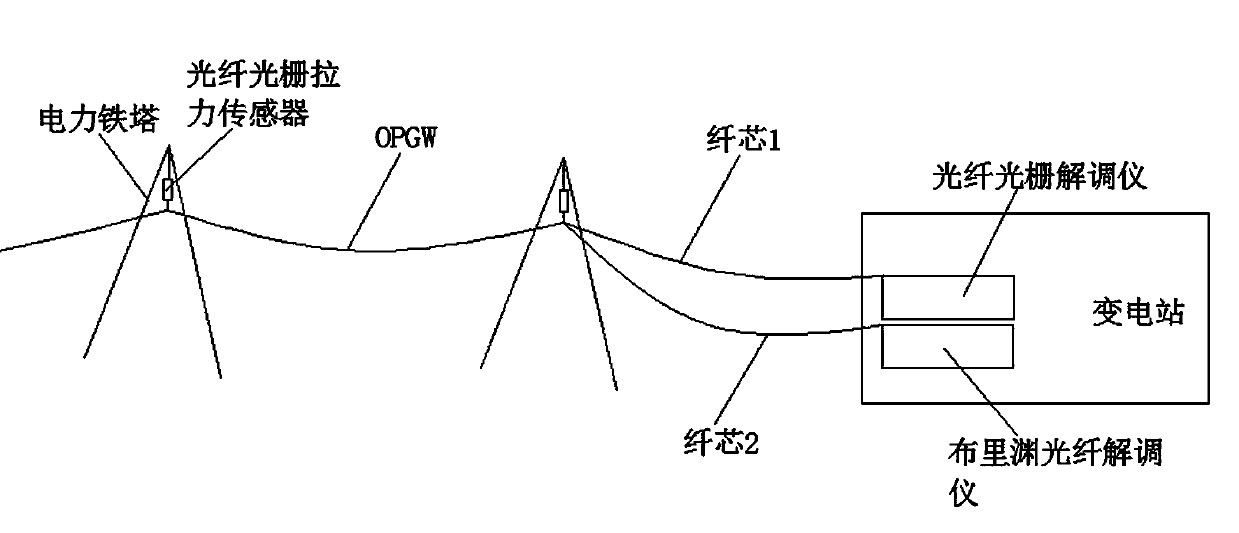

Provided is a method for monitoring an OPGW online with the use of the optical fiber sensing technology. According to the method, an OPGW is weighed by using an optical fiber Bragg grating tension sensor, a sensing signal of the optical fiber Bragg grating tension sensor is transmitted through an optical fiber core (1) of the OPGW and is connected with an optical fiber Bragg grating demodulator in a substation, and a Brillouin optical fiber demodulator in the substation monitors the OPGW through the optical fiber core (1) of the OPGW. The method can overcome the problem of cross sensitivity of temperature and strain of the Brillouin optical fiber demodulator, can be used for monitoring temperature, ice covering and ice melting states of the OPGW in real time in combination with other meteorological information and can be used for positioning a fault point with the use of the Brillouin optical fiber demodulation technology.

Description

technical field [0001] The invention relates to a method for online monitoring of OPGW by using optical fiber sensing technology, which belongs to the field of optoelectronic measurement technology. Background technique [0002] OPGW (Optical Fiber Composite Overhead Ground Wire) puts the optical fiber in the ground wire of the overhead high-voltage transmission line to form an optical fiber communication network on the transmission line. This structure has both ground wire and communication function, which is of great significance to both power grid and communication. However, OPGW accidents frequently occur due to factors such as lightning strikes, short circuits, and icing, resulting in huge economic losses and great social impact. It is important to monitor it. At present, electronic sensors and image monitoring methods are mostly used to monitor the entire transmission line. Both methods are susceptible to strong electromagnetic interference, and due to power supply ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01K11/32G01B11/16G01K11/322

Inventor 杨洪磊梁仕斌曹敏李川苗雪鹏薛俊华

Owner YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com