Method used for manufacturing at least one characteristic of measured gas

A detector and gas technology, applied in the field of oxygen component detection, which can solve problems such as inability to use materials, weakening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

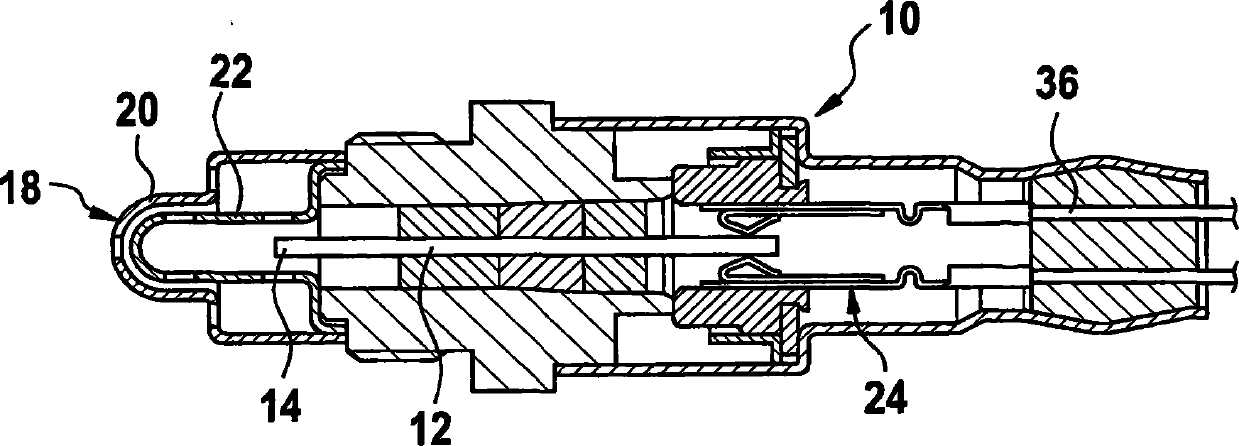

[0041] figure 1 A schematic cross-sectional view of the detector 10 is shown. Sensor 10 is designed, for example, as an air intake sensor. The air intake sensor is used to control the air-fuel mixture of the internal combustion engine, so that by measuring the concentration of the oxygen component in the exhaust gas, it can adjust the mixture as stoichiometric as possible, so that the emission of harmful substances can be minimized through the most optimal combustion. Within the scope of the invention, the measurement space can therefore be an exhaust system of the internal combustion engine. The basic structure and mode of function are described, for example, in Konrad Reif (published): Sensors in Motor Vehicles, first edition 2010, pp. 160-165. Using broadband air mass sensors, in particular planar broadband air mass sensors, it is possible, for example, to determine the oxygen concentration in the exhaust gas over a large area and thus to draw conclusions about the air-fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com