Full-voltage full-loop self-checking capacitive-type electroscope

An electroscope and full-circuit technology, applied in the field of electroscope, can solve problems such as inconvenience of carrying, lack of full voltage switching, and inconvenient operation by staff, and achieve the effects of avoiding accidents, simplifying the configuration of safety tools, and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

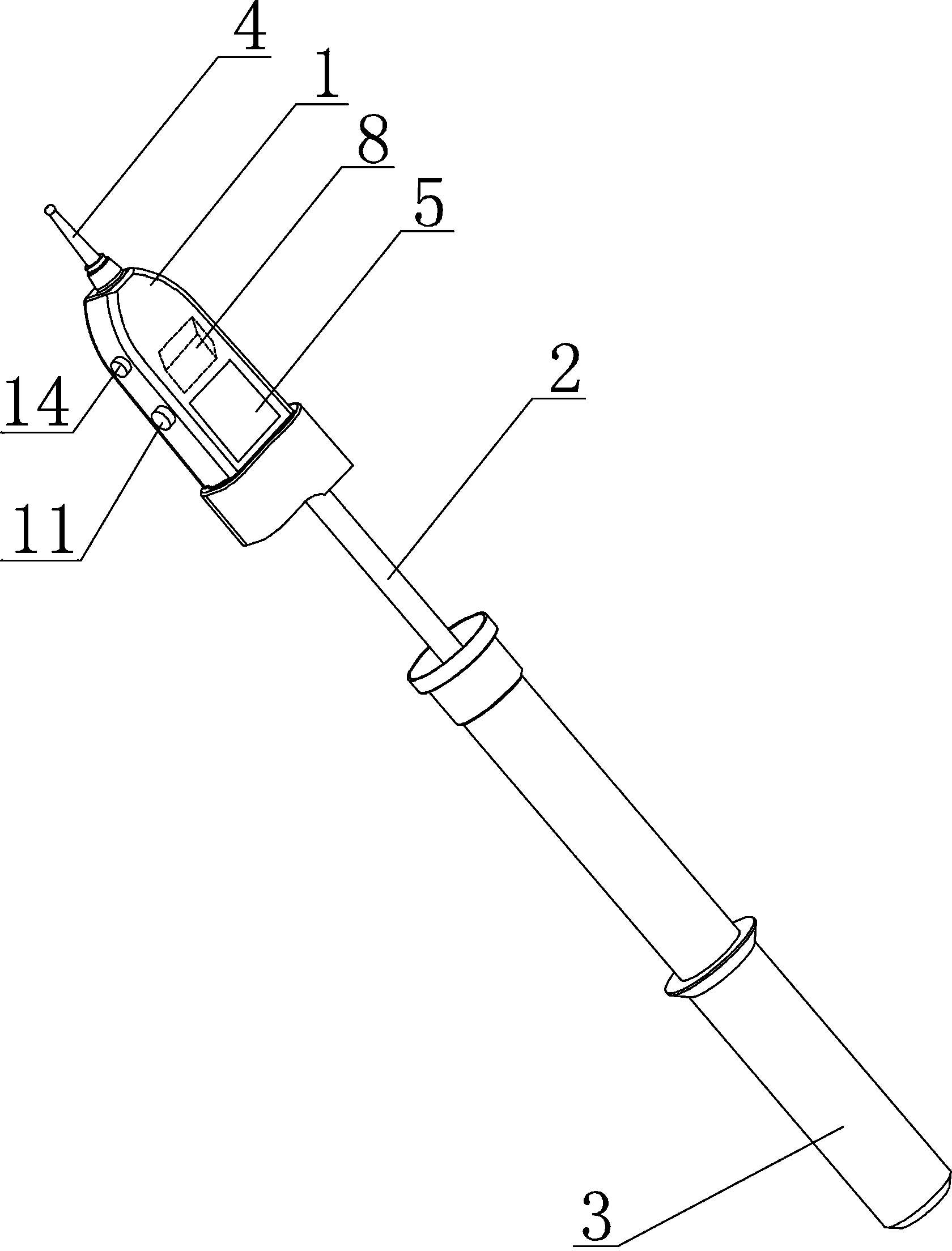

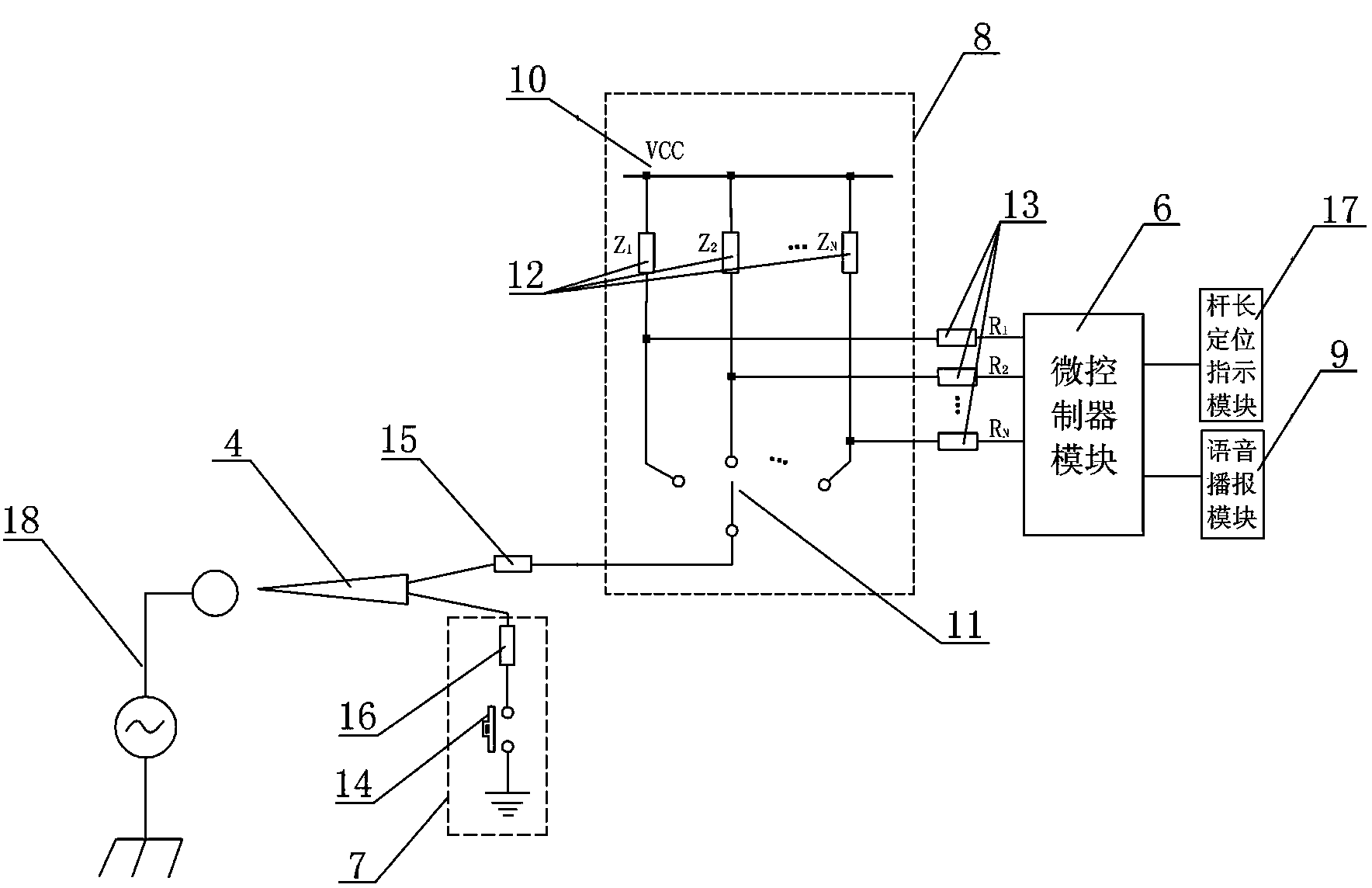

[0012] The present invention will be further elaborated below by means of the accompanying drawings and examples.

[0013] Such as figure 1 and figure 2 Shown: a full-voltage full-circuit self-test capacitive electroscope, including an electroscope circuit box 1, an insulating operating rod 2 and a handle 3, the insulating operating rod 2 is a retractable structure, and the scale value is also marked on the rod . The electroscope circuit box 1 is provided with detection probes 4 and a display screen 5 . The electroscope circuit box 1 includes a microcontroller module 6 and a self-test circuit module 7 . The electroscope circuit box 1 is provided with a voltage level conversion circuit box 8 and a voice broadcast module 9, and the voice broadcast module 9 referred to here is actually a sound generator. Since the pressure level conversion circuit box body 8 is inside the electroscope circuit box body 1, it is represented by a dotted line among the figures, as figure 1 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com