Method for keeping PLC device power-down data

A technology of power-down retention and equipment data, applied in the redundancy of computing for data error detection, response error generation, etc., can solve the problem of difficulty in ensuring the real-time and accuracy of industrial field data protection, and the lack of time series for stored data. It can not fully guarantee the correctness of power-off data, etc., to achieve the effect of strong practicability, lower product cost, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

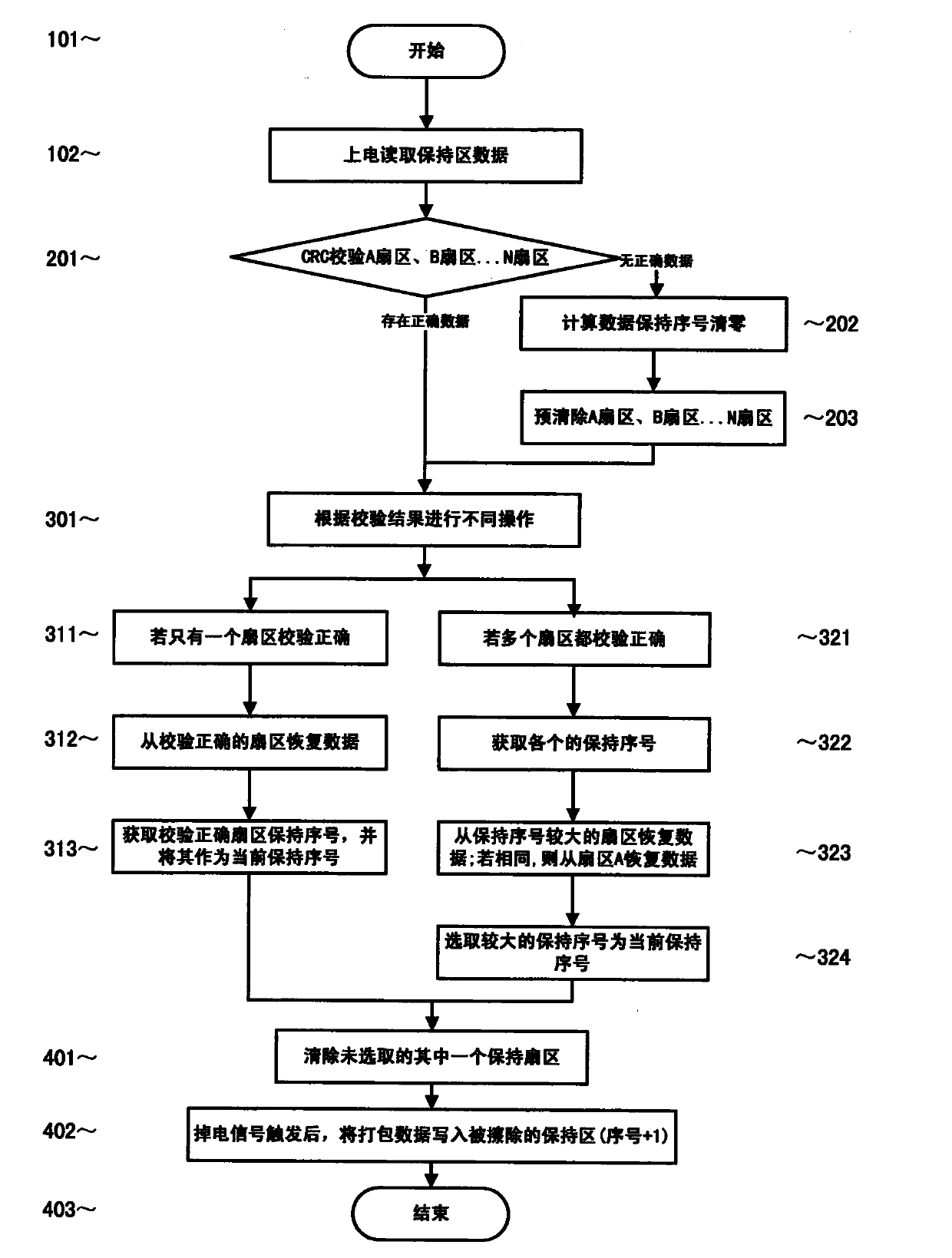

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0016] combine figure 1 , the present invention provides a method for keeping data of PLC equipment in power failure. The basic power-down retention design that will not directly lose power to ensure that the power-down data has a storage time of 2 to 5s. The specific steps are:

[0017] Step 1. When the PLC device is running normally, erase an unused sector of the power-off storage space as the backup sector for the next abnormal power-off of the PLC device;

[0018] Step 2. When the PLC device is abnormally powered off, add 1 to the current update sequence number, package the power-down data into a power-down data packet and store it in the backup sector obtained in step 1. The backup sector containing the power-down data packet The area becomes the holding sector, and the power-down data packet includes at least the holding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com