Auxiliary design system and design method for traction system of rail vehicle

A traction system and aided design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as restricting the design scheme, difficult to know the dynamic performance of the key components of the traction system, such as torque ripple, etc., to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

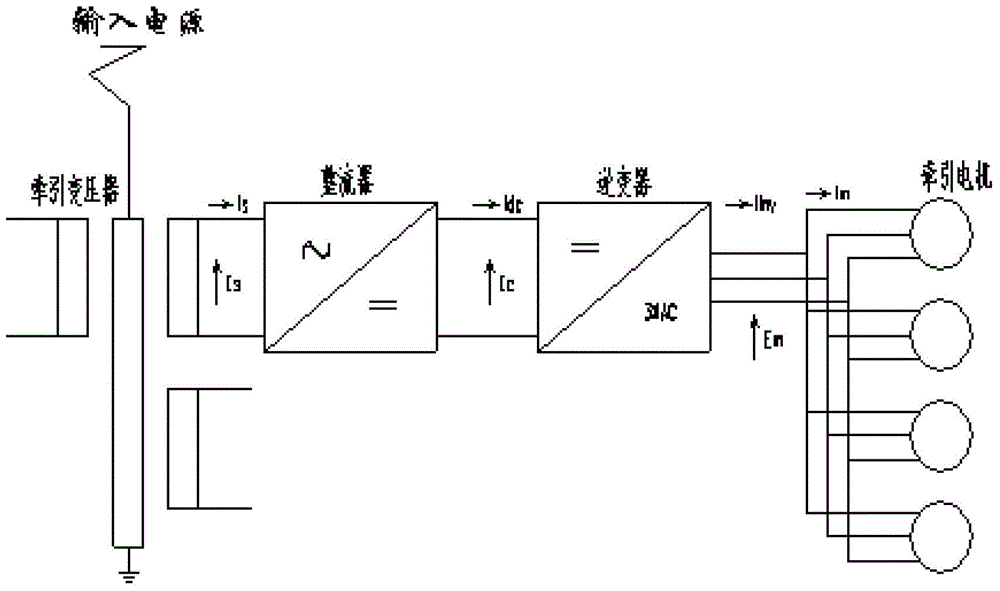

[0024] Such as figure 1 As shown, the traction system of rail vehicles mainly includes input power supply, traction transformer, rectifier, inverter, traction motor and so on. The traction system reduces the voltage of the high-voltage electricity introduced by the roof through the traction transformer, and after the frequency conversion and voltage conversion by the rectifier and inverter, it is sent to the traction motor in a controllable and appropriate manner, and the traction motor drives the vehicle to run.

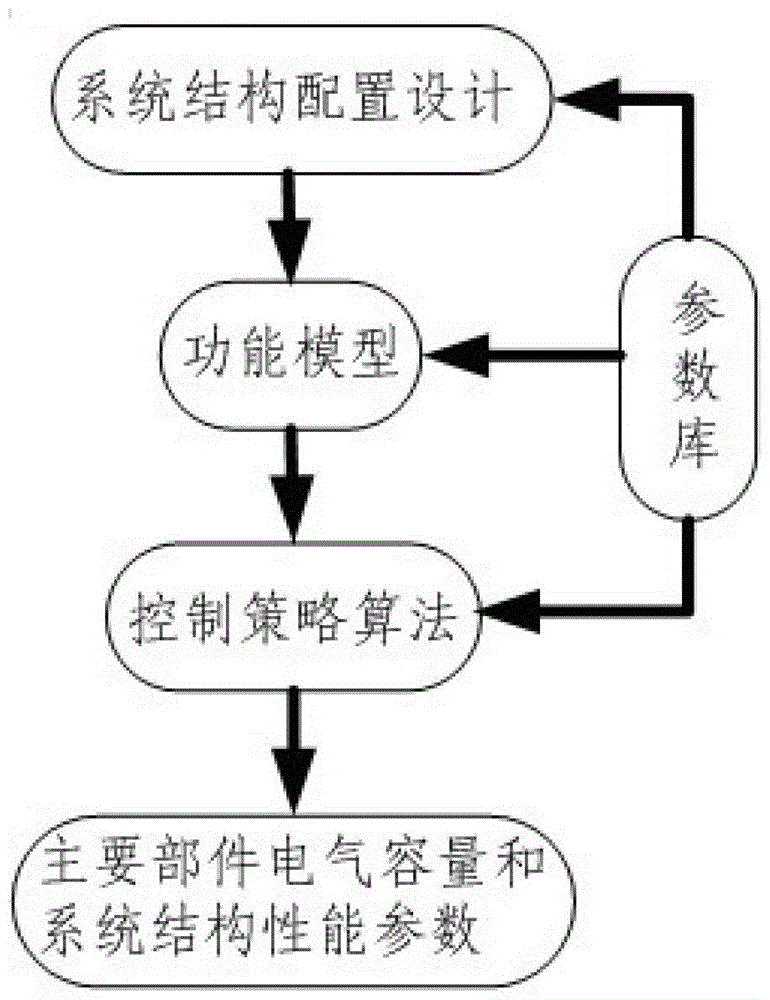

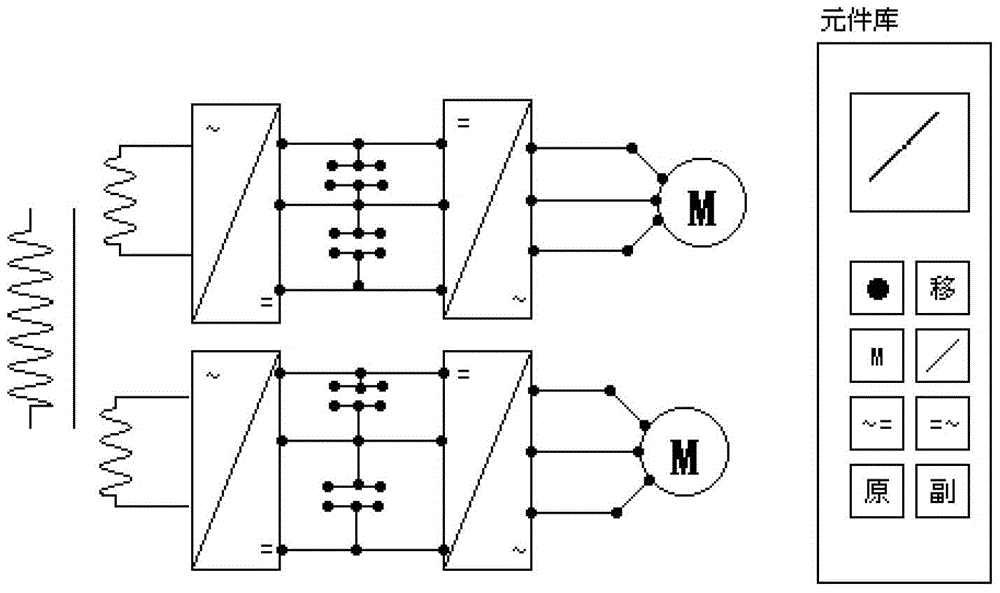

[0025] Such as figure 2 As shown, the auxiliary design system of rail vehicle traction system is used to assist designers in the design of traction system, mainly including database module, component function model library module, algorithm library module and structural configuration design module.

[0026] The structural configura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com