Tangential-magnetized magnetic flux reversed mixed excitation linear motor

A magnetic flux reversal, hybrid excitation technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of troublesome manufacturing, processing and installation, restricting the ability of motor magnetic adjustment, irreversible demagnetization of permanent magnets, etc., to improve the magnetic adjustment. Efficiency, reducing the risk of irreversible demagnetization, the effect of efficiency optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below according to the drawings and specific embodiments of the specification.

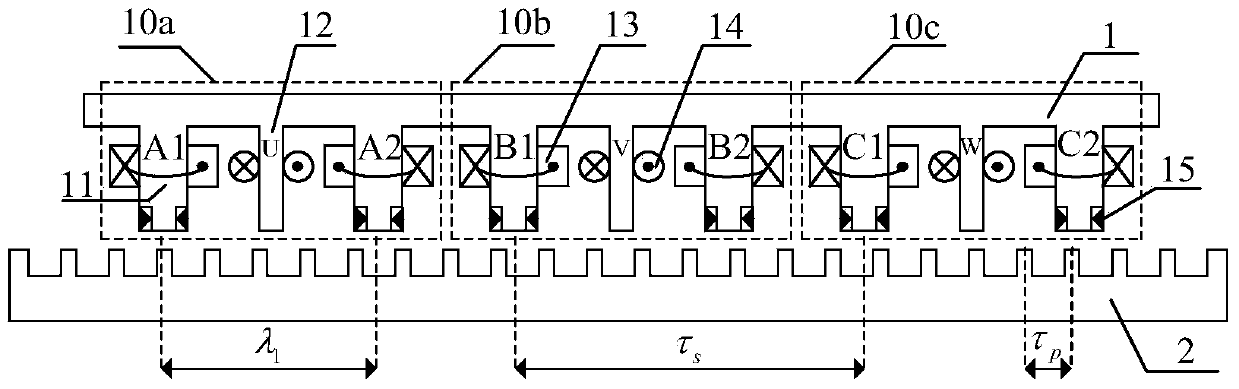

[0023] Such as figure 1 As shown, a tangentially magnetized magnetic flux reverse hybrid excitation linear motor includes a primary mover 1 and a secondary stator 2, and the primary mover 1 is composed of a primary a module 10a, a primary b module 10b and a primary c The modules 10c are connected in parallel, the primary mover 1 and the secondary stator 2 are made of magnetically permeable materials, the secondary stator 2 is a salient pole structure with equal tooth width, and the primary mover 1 There is an air gap between the primary module and the secondary stator 2. Two armature teeth 11 are arranged on both sides of the primary module, and an excitation tooth 12 is arranged between the two armature teeth 11. Each of the A set of armature windings 13 is wound on each armature tooth 11, and a set of field windings is wound on each of said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com