Low-space harmonic single/double-layer winding radial flux five-phase permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and radial flux, which is applied to the shape/style/structure of synchronous motors with stationary armatures and rotating magnets, motors, and winding conductors. Problems such as large eddy current loss and large harmonic content of the magnet can achieve the effect of reducing harmonic content, reducing calorific value, and reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

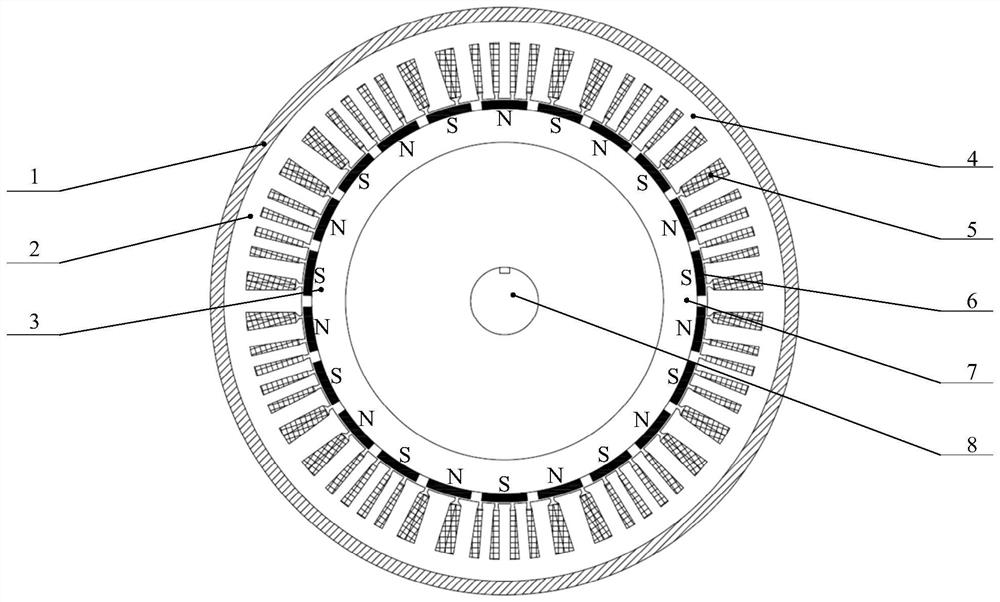

[0046] Specific implementation mode one: the following combination Figure 1-13 Describe this embodiment mode, the radial flux five-phase permanent magnet synchronous motor of low spatial harmonic single-layer winding described in this embodiment mode, it comprises casing (1), stator (2), rotor (3), rotating shaft (8 ), the stator (2) includes a stator core (4) and a single-layer hybrid winding (5), the rotor (3) includes a rotor core (7) and a permanent magnet (6), and the rotor (3) is arranged on a rotating shaft (8) , the stator (2) is arranged on the outside of the rotor (3) and the rotating shaft (8), the outer circular surface of the stator (2) is fixed on the inner circular surface of the casing (1), and the connection between the stator (2) and the rotor (3) There is an air gap between them, and the length of the air gap is L;

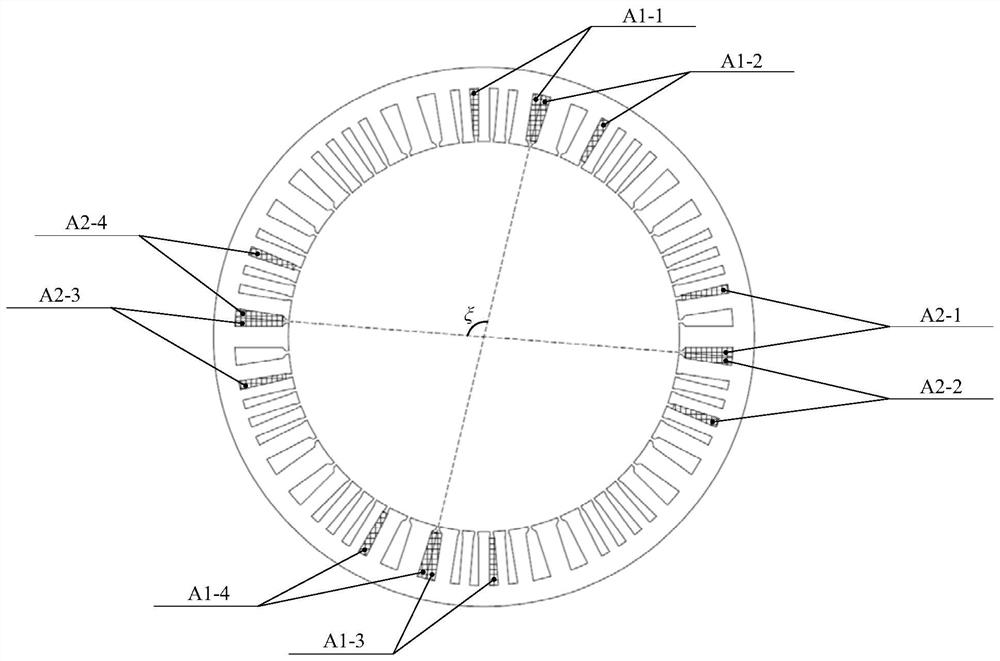

[0047] The stator is provided with 10 stator slot units along the circumference, see Figure 4 , clockwise are unit 1 to unit 10, each stato...

Embodiment 1

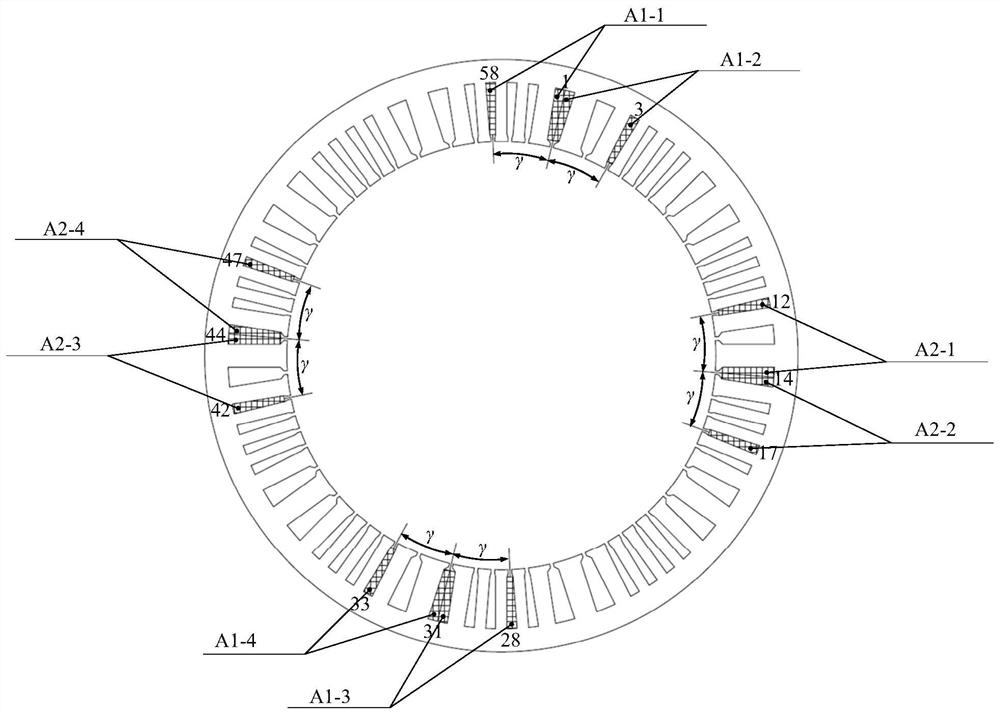

[0059] Embodiment 1. According to the limited conditions, select the coil pitch as γ value and ξ value: γ=15.75°, ξ=99°, then the angle λ between the double-layer winding slots 1 is 9°, the angle λ between the single-layer winding slot and the double-layer winding slot 2 is 6.75°, the left and right pairs of adjacent single-layer winding slots in each stator slot unit, the angle λ between the two single-layer winding slots of each pair 3 is 4.5°, the angle λ between the middle two adjacent single-layer winding slots in each stator slot unit 4 is 4.5°,

[0060] During normal operation, the five-phase windings of the motor pass through the current in the form of cosine as follows:

[0061]

[0062] Among them: i a i b i c i d and i e are the currents of A, B, C, D and E phase windings respectively;

[0063] ω e is the electrical angular velocity of the motor;

[0064] I m is the current amplitude.

[0065] Through two-dimensional finite element analysis, the synth...

Embodiment 2

[0071] Embodiment 2. According to the limited conditions, select the coil pitch as γ value and ξ value: γ=16°, ξ=100°, then the angle λ between the double-layer winding slots 1 is 8°, the angle λ between the single-layer winding slot and the double-layer winding slot 2 is 8°, the left and right pairs of adjacent single-layer winding slots in each stator slot unit, the angle λ between the two single-layer winding slots of each pair 3 is 4°, the angle λ between the middle two adjacent single-layer winding slots in each stator slot unit 4 is 4°,

[0072] During normal operation, the five-phase windings of the motor pass through the current in the form of cosine as follows:

[0073]

[0074] Among them: i a i b i c i d and i e are the currents of A, B, C, D and E phase windings respectively;

[0075] ω e is the electrical angular velocity of the motor;

[0076] I m is the current amplitude.

[0077] Through two-dimensional finite element analysis, the synthetic magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com