Charging tray type feeder, electronic component loading device and carrier transferring method

A technology of electronic components and feeders, applied in the direction of electrical components, electrical components, etc., can solve problems such as wrong transfer, and achieve the effect of preventing human errors and saving labor and working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

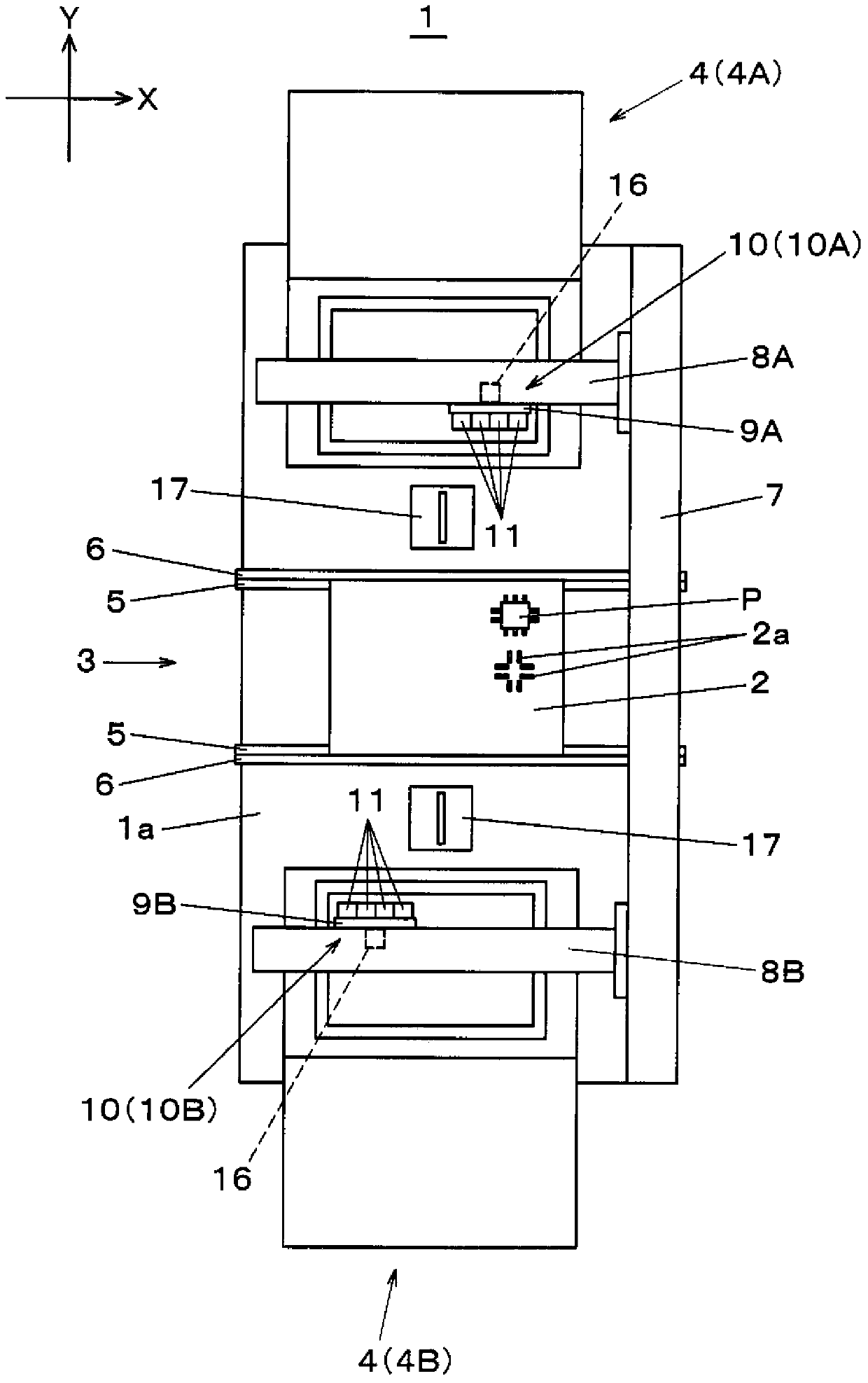

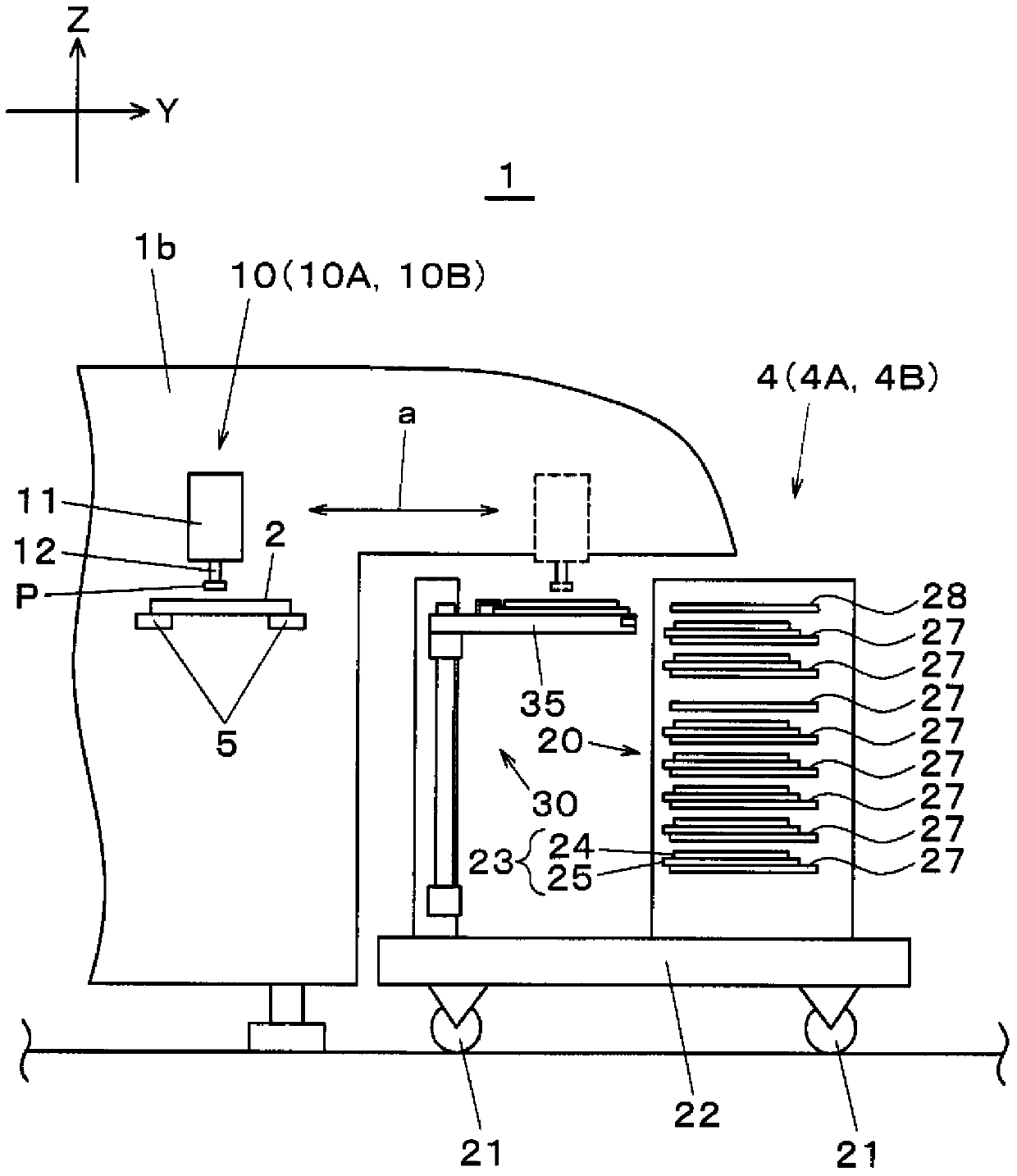

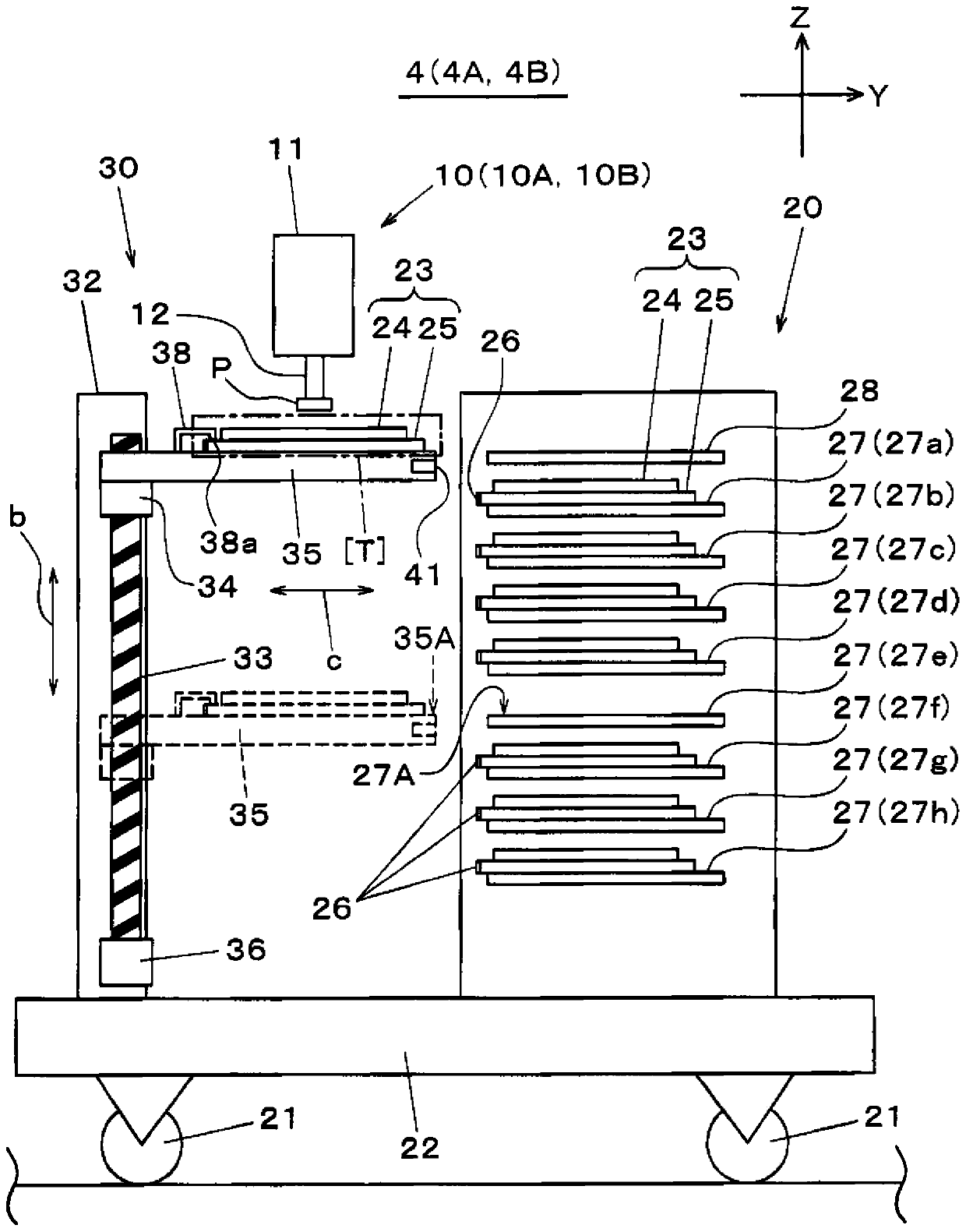

[0041] First, refer to figure 1 The electronic component mounting device according to Embodiment 1 will be described. The electronic component mounting device 1 is composed of an electronic component mounting device main body and a tray feeder 4 (4A, 4B). The substrate 2 is transported along the substrate transport direction, that is, the X direction, and positioned at the specified working position ( figure 1position of the substrate 2 shown), and the mounting head 10 ( 10A, 10B) as an electronic component mounting portion for mounting the electronic component P on the electrode 2 a of the substrate 2 positioned by the substrate conveying portion 3 ; The tray feeders 4 ( 4A, 4B) serve as component supply units and are respectively provided on both sides of the base 1 a facing in the Y direction perpendicular to the X direction, and supply electronic components P to the mounting head 10 . In addition, the electronic component mounting main body is composed of a cover member ...

Embodiment approach 2

[0087] Next, refer to Figure 14 The structure of the electronic component mounting apparatus 100 of this Embodiment 2 is demonstrated. In addition, the difference from the electronic component mounting device 1 of the first embodiment is only the tray feeder, and the same components as the electronic component mounting device 1 will be described using the same reference numerals. The tray feeder 400 constituting the electronic component mounting apparatus 100 is provided with a suction head 401 that can hold the carrier 23 moved to the component supply position [T] via the tray 24. The suction nozzle 401a for sucking and holding the electronic component P. The suction head 401 can be moved in the X and Y directions by a suction head moving mechanism not shown. In addition, the suction nozzle 401a can be moved in the Z direction by a suction nozzle raising and lowering mechanism not shown.

[0088] In addition, a shuttle 402 which has a horizontal surface on which the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com