Magnetic bearing assembly

A technology of permanent magnet and magnetic bearing, applied in the field of magnetic bearing, can solve the problems of expensive shielding and limited effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

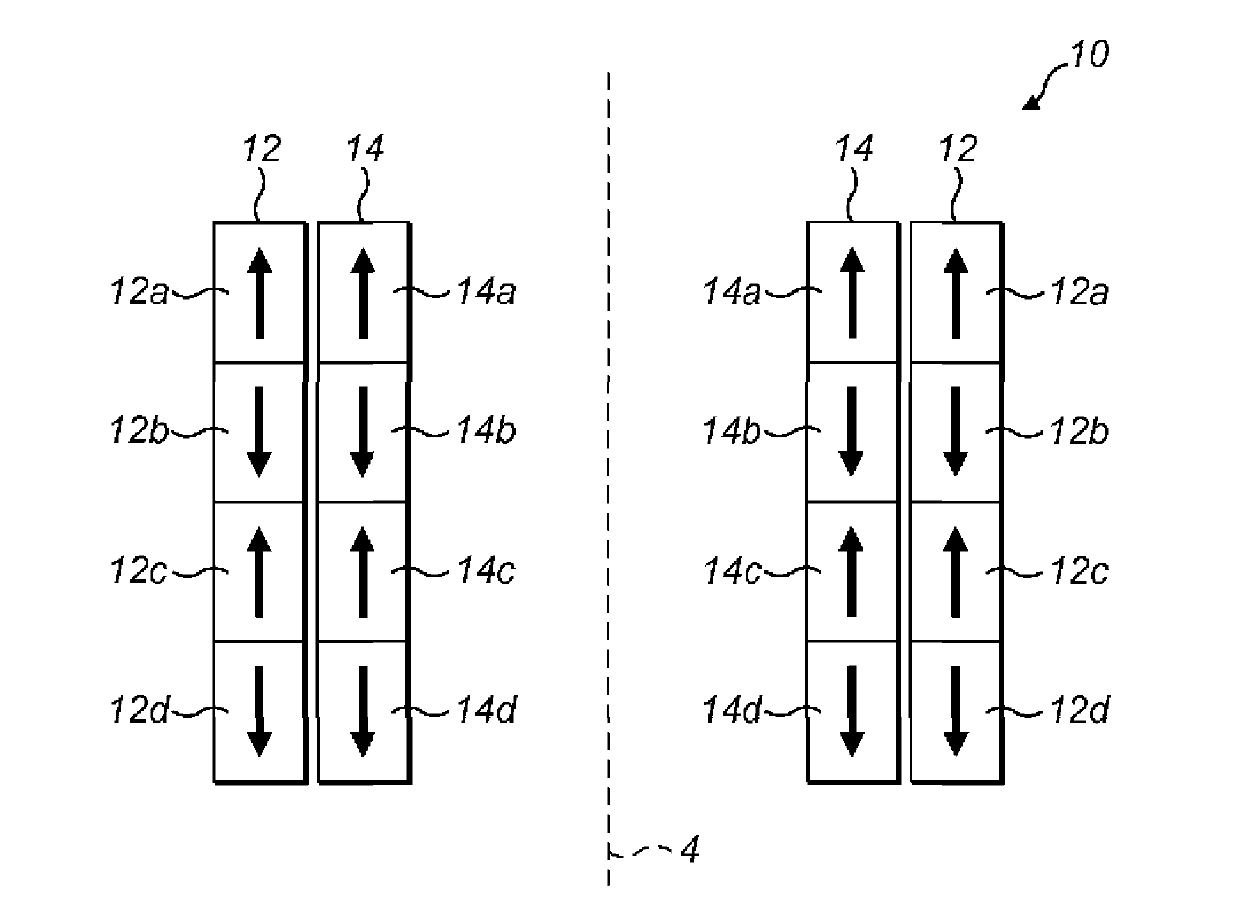

[0032] image 3 is a schematic diagram of an apparatus for performing measurements according to the invention. Magnet measurement station (or magnetic alignment equipment) 50 includes magnet rotation sections 58 , 60 , 62 , 64 , 66 and magnetic field measurement sections 56 , 54 , 68 , 70 , 72 .

[0033] The magnet rotation section includes a motor 62 for rotating the magnets. Motor 62 is driven by a speed control device 64 (eg, an inverter) and a power source 66 . A non-magnetic spindle or rotor 60 attached to a motor 62 extends up through the non-magnetic table 52 into a magnet mount 58 (also non-magnetic). The motor is positioned sufficiently far from both the magnet mount and the measurement station so that any magnetic field emanating from said motor 62 does not interfere with any measurements taken. The rotor is preferably supported by non-magnetic bearing means (not shown) at the end remote from the motor, proximate the magnet mount 58, to ensure that the magnets can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com