Three-dimensional food extruding and forming machine

A technology of extrusion molding machine and food, which is applied in the field of three-dimensional food extrusion molding machine and food three-dimensional molding equipment, can solve the problems of few varieties, serious dependence on operator technology, and low processing and production efficiency, so as to increase changes and realize customization and the effect of quantifying demand and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

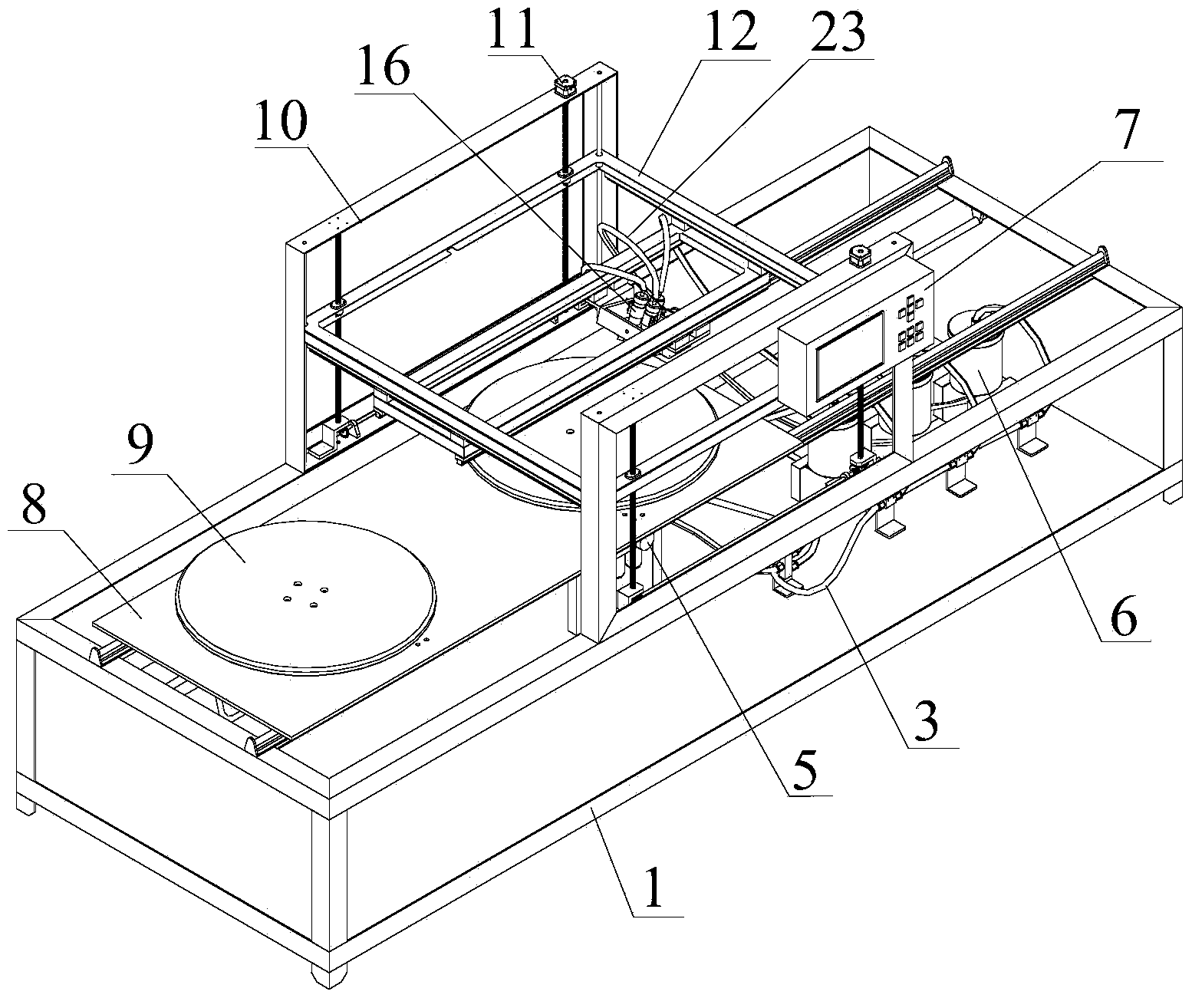

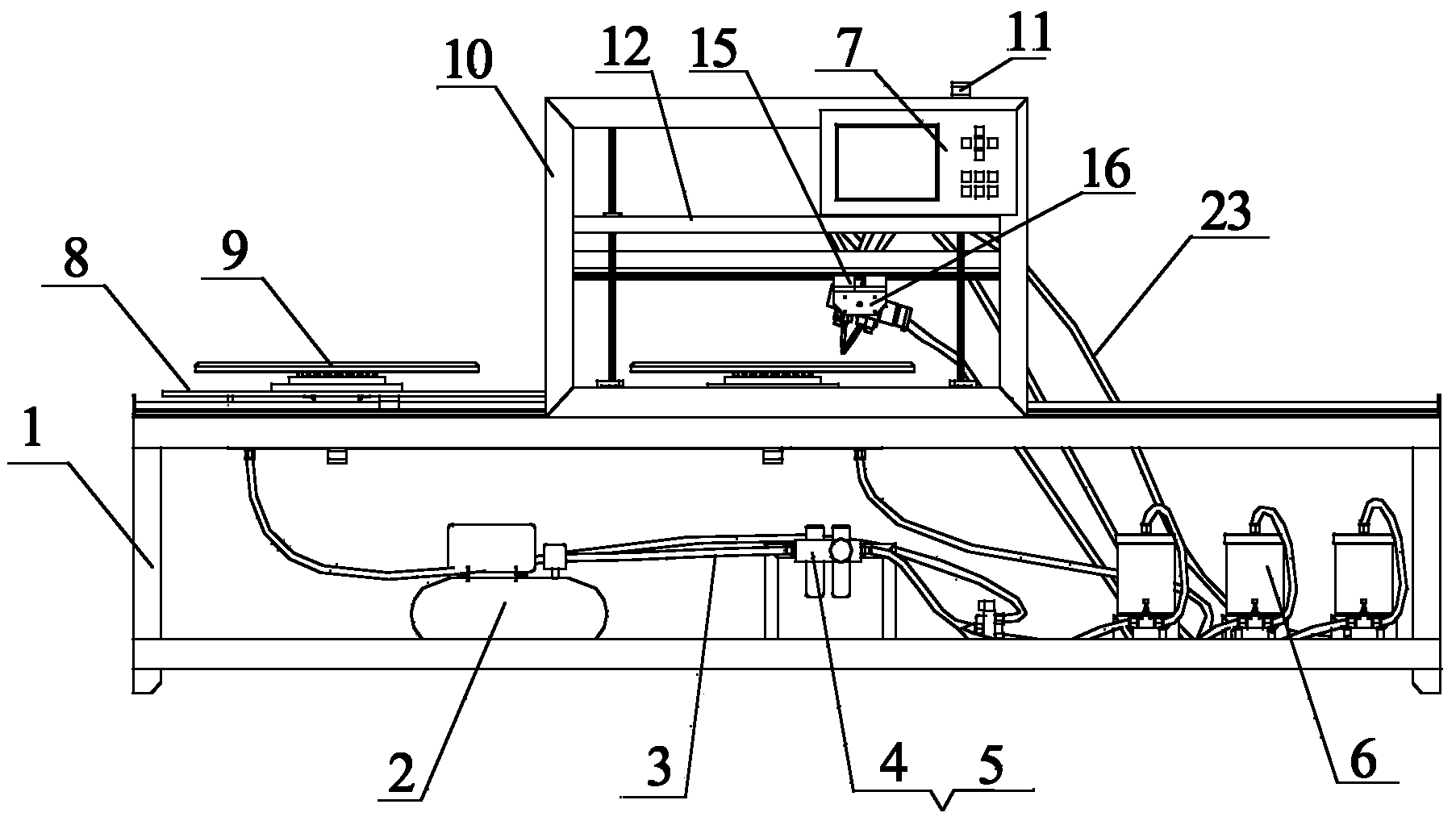

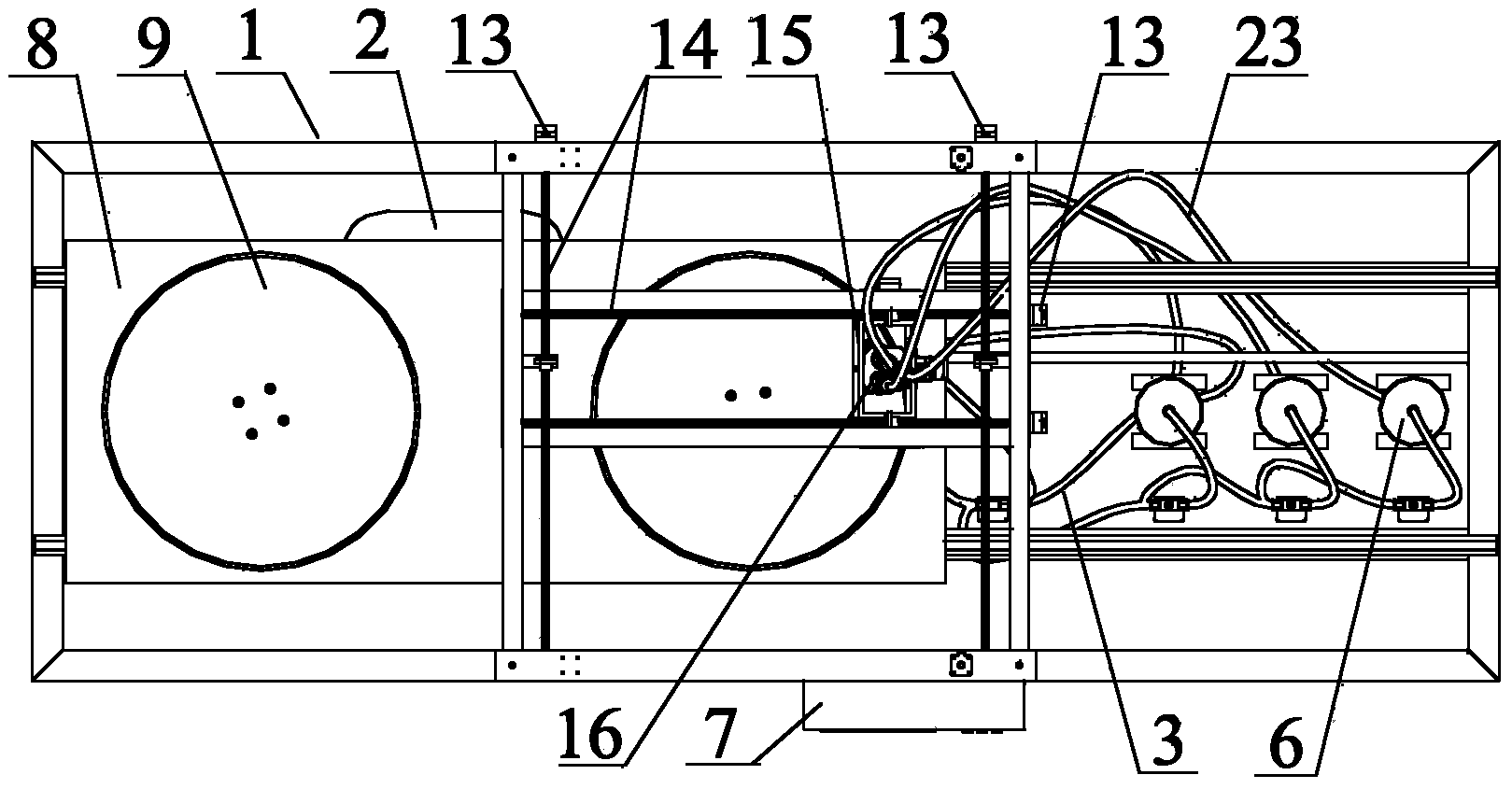

[0019] A three-dimensional food extrusion molding machine, such as figure 1 and figure 2 As shown, it comprises a compressed air storage tank 2 installed at the bottom of the frame 1, a feeding system composed of a colloidal food material tank 6 connected to the gas storage tank 2 through an air pipe 3, a pressure regulating valve 4, a filter 5, A control system consisting of a computer and a control panel 7 connected thereto, a transmission device consisting of a mobile platform 8 driven by a stepping motor arranged on the table top of the frame 1 and a rotating chassis 9 installed on the mobile platform 8, the frame 1 A lifting frame 12 driven by a Z-axis servo motor 11 is housed on the bracket 10 fixed in the middle section, and a moving bracket 15 driven and connected by two groups of X and Y-axis servo motors 13 and a transmission scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com