Novel beater

A technology of beater and mixing tank, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., which can solve the problems of easy safety accidents, manual lifting of beating and unloading materials, inconvenience, etc., and achieve a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

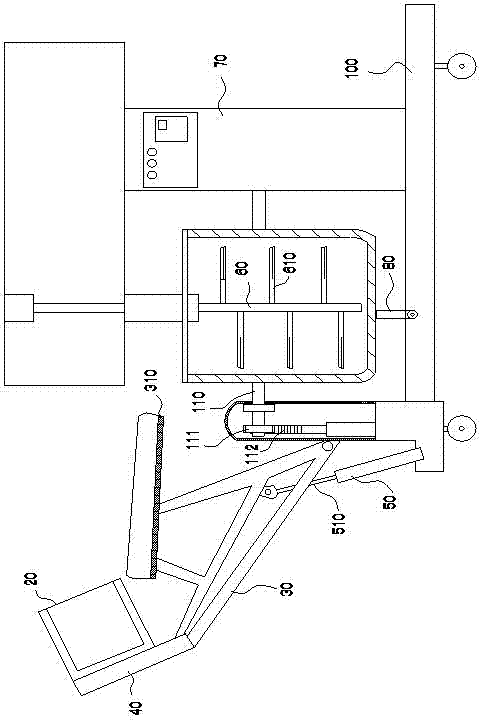

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

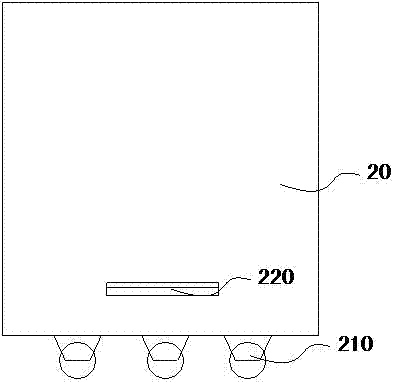

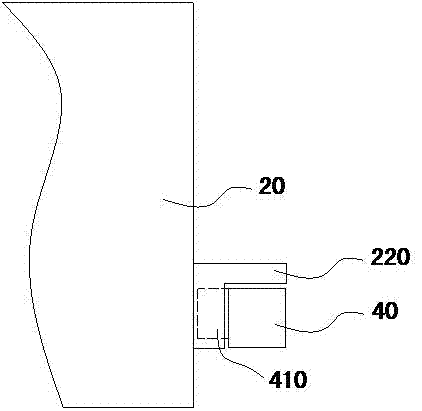

[0021] Such as Figure 1~2 As shown, the specific embodiment of the present invention is: a kind of beating machine, comprising a mixing tank 10 and a feed cart 20 for transporting meat slurry, the size of the feed cart 20 is designed according to food standards, and the bottom of the feed cart 20 is provided with Roller 210, the side wall of the feeding car is provided with turning plate 220.

[0022] The front side of the mixing bucket 10 is provided with a support, and the support is hinged with a turning frame 30. The turning frame 30 is provided with a feeding guide plate 310, and both sides of the feeding guiding plate 310 are also provided with baffle plates. The turning frame 30 The upper end is connected with a pair of feeding cart fixing rods 40 which form an obtuse angle with the material guide plate.

[0023] Such as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com