Lifter overload protection device and fault diagnosis method

A technology of overload protection and elevators, which is applied in elevators, transportation and packaging, etc., can solve problems such as overload protection malfunctions, electrical difficulties, and load display errors, and achieve the effects of avoiding misoperation and simple fault testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

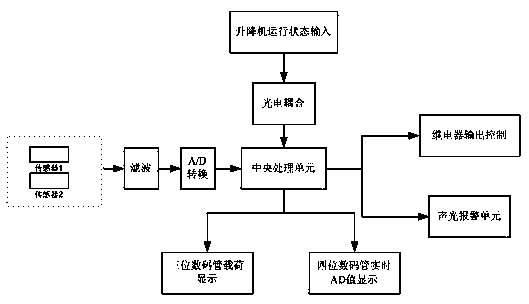

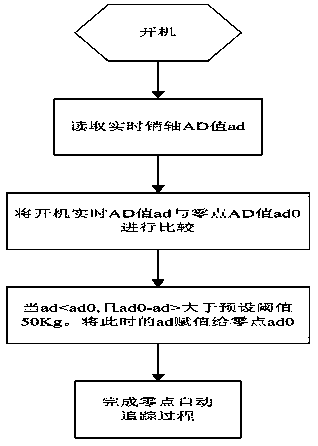

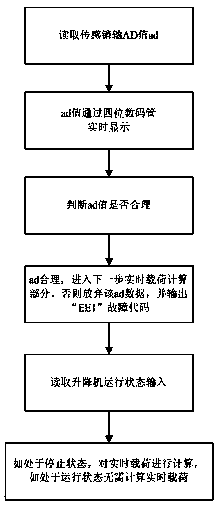

[0039] This embodiment provides an elevator overload protection device, such as figure 1 and figure 2As shown, it includes sensor pin shaft, filter circuit, AD conversion circuit, central processing unit, elevator running state input, photoelectric coupling circuit, relay control output circuit, sound and light alarm unit, three-digit digital tube load display unit and four-digit digital The real-time AD value display unit, the sensing pin shaft is arranged between the cage body and the trolley frame of the elevator, and the sensing pin shaft is connected to the signal receiving end of the central processing unit through the filter circuit and the AD conversion circuit in turn. The photoelectric coupling circuit is connected to the signal input end of the central processing unit, and the signal output end of the central processing unit is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com