Method and device for changing ozone addition sequence in microbubble ozone-coagulation-air floatation process

A technology of micro-bubbles and ozone, applied in chemical instruments and methods, flotation water/sewage treatment, oxidized water/sewage treatment, etc. The effect of small footprint and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

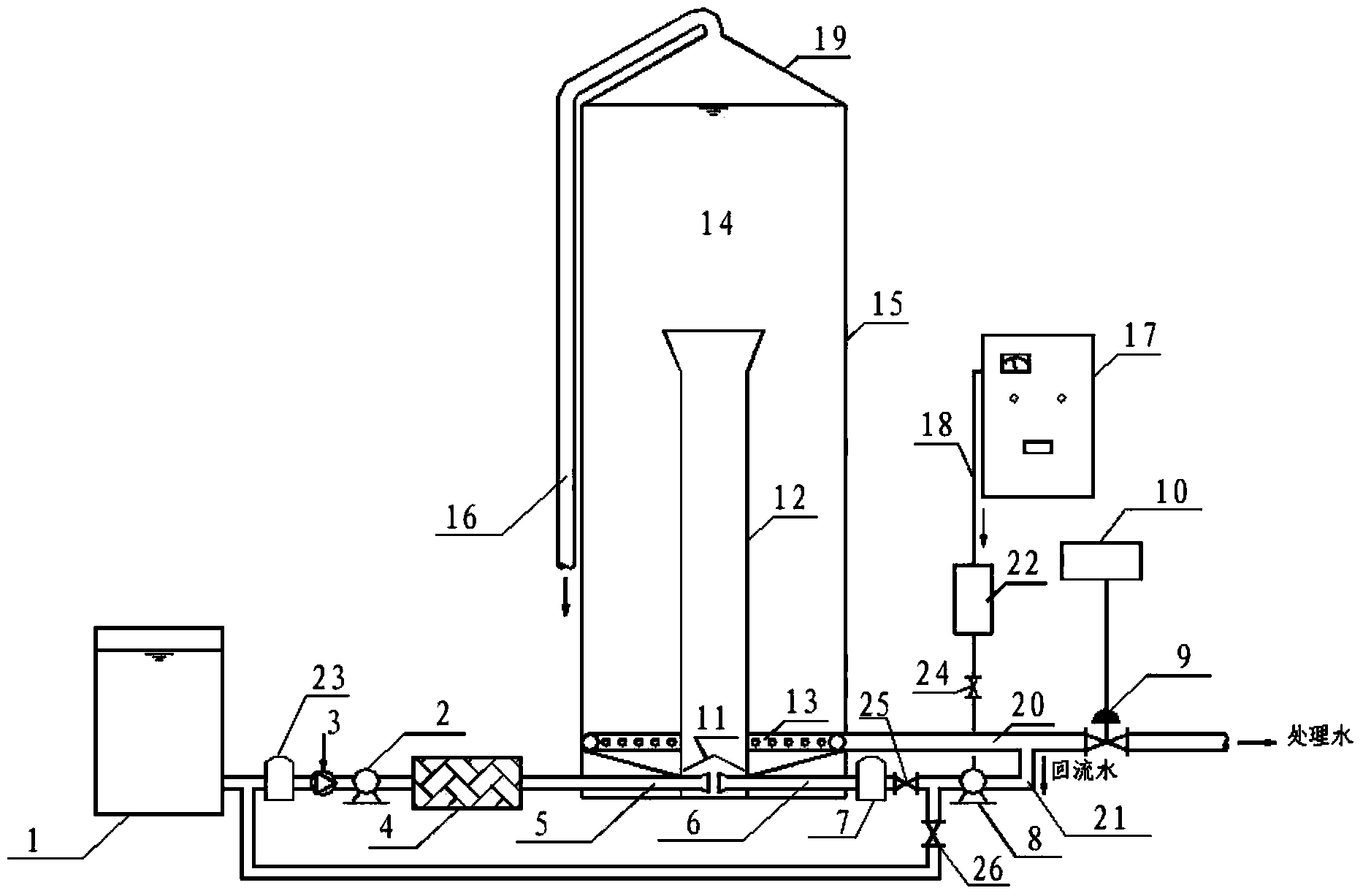

[0024] The technical solution of the present invention will be further described in detail with the accompanying drawings, but the present invention is not limited to these embodiments.

[0025] Such as figure 1 As shown, a micro-bubble ozone-coagulation-air flotation integrated device that can change the ozone dosing sequence includes a raw water tank 1, and the water outlet of the raw water tank 1 is sequentially connected to 2# dissolved air tank 23 and coagulant dosing Port 3, raw water pump 2 and hydraulic mixer 4, and then umbrella mixer 11, the ozone generated by ozone generator 17 passes through dissolved air pump 8, and is divided into two paths, respectively connected to the outlet of raw water tank 1 and 1# dissolved air tank , and respectively set the 3# valve and the 2# valve, and connect the 1# container pipe all the way to the umbrella mixer 11, the umbrella mixer 11 is located in the air flotation separator 15, and the outlet water of the air flotation separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com