Method for replacing and installing coal supporting baseplate in tamping coke oven coal charging car

A technology for supporting the coal floor and an installation method, which is applied in the field of metallurgy, can solve problems such as long debugging time, vibration of the new coal floor, and increased workload, and achieve the effects of simple and clear steps, reduced construction costs, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the replacement and installation method of the coal support bottom plate in the tamping coke oven coal charging car of the present invention will be described in detail with reference to the accompanying drawings.

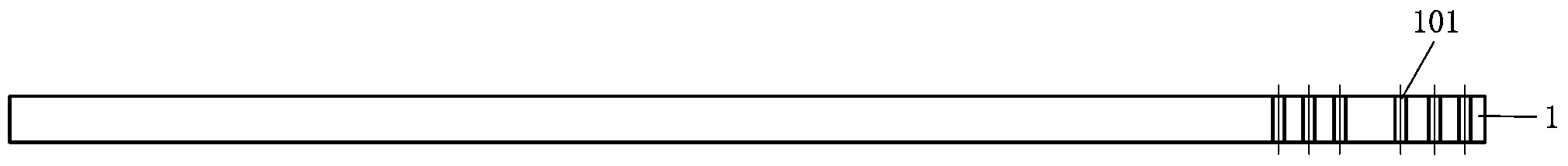

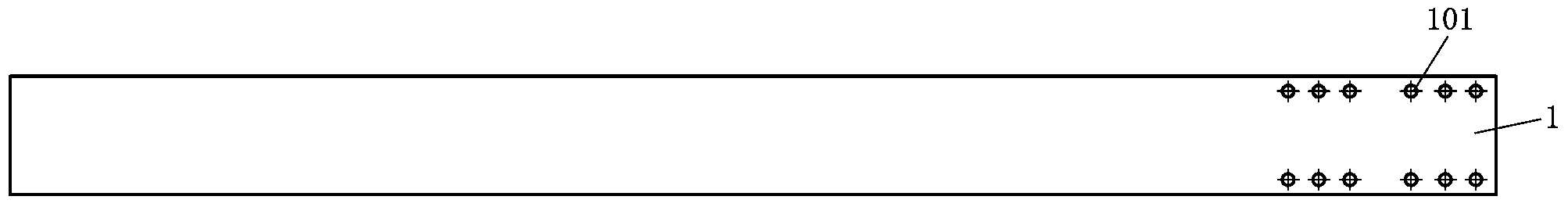

[0029] Figure 1A Shows the front view structure of the coal support floor, Figure 1B It shows the top view structure of the coal support floor, which is located at the bottom of the coal box of the coal loading car. The size of the coal support floor is 16900mm*450mm*80mm and the mass is 5t. The coal support floor is driven by a chain and can move back and forth , Send the briquettes to the coking chamber of the coke oven.

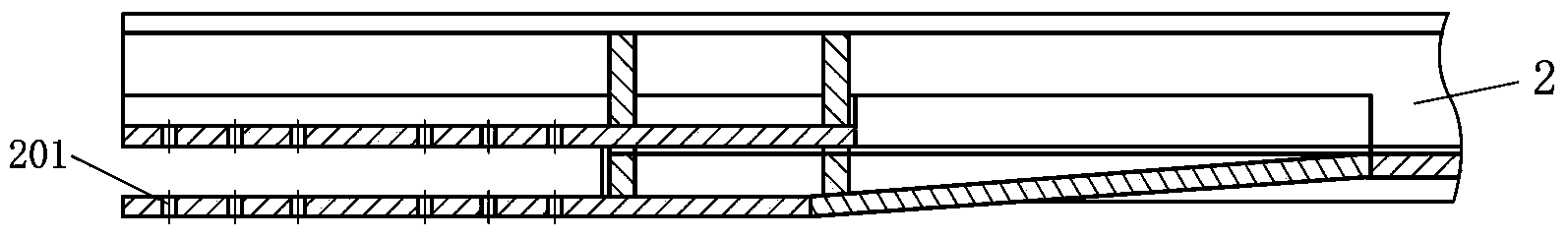

[0030] Specifically, the coal-supporting bottom plate 1 is located at the bottom of the coal box 5 of the coal-loading car and the two sides of the coal-supporting bottom plate 1 are the box walls of the coal-carrying coal box. The coal-supporting bottom plate 1 is connected with the bottom plate connector 2 below by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com