Production method and product of fermented litchi ice wine

A production method and fermentation technology, applied in the production method of fermented lychee ice wine and its product field, can solve the problems of lychee juice oxidative browning, low lychee juice yield, and destruction of aroma components, so as to speed up clarification and achieve good brewing effect , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

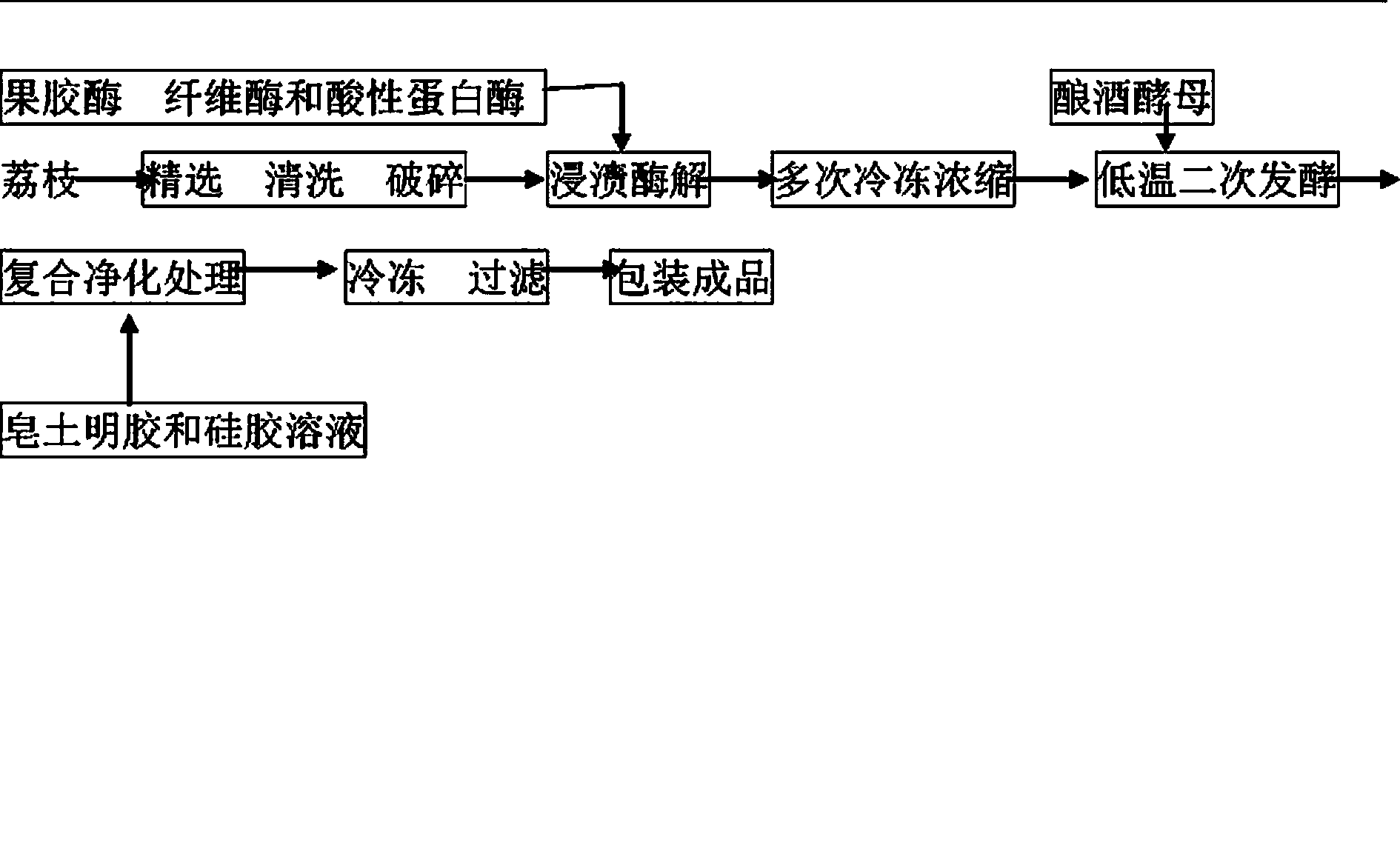

Method used

Image

Examples

Embodiment Construction

[0021] Firstly, select raw lychee fruits, choose fresh fruits that are more than eight mature, and remove rotten fruits, fallen fruits, and fruits that are too small and not mature enough. Thoroughly clean the qualified products, shell and remove the core, use a beater to crush and remove the core, move the processed lychee pulp into the dipping tank, add compound enzymatic enzymes to the dipping liquid, Add 10mg-30mg of pectinase, 120mg-250mg of cellulase and 120mg-150mg of acidic protease as enzymolysis agent, and stir, control the dipping temperature at 9°C-13°C, enzymolysis for 8-11 hours, to obtain fermented Lychee Juice. Put the lychee juice into the freezing tank by using the pump, gradually lower the temperature in the range of -3℃~-8℃, and carry out multiple freezing and concentration, while continuously removing the generated ice cubes. When the sugar content of the juice reaches 350 g / L~380g / L L (based on glucose), freeze concentration can be stopped.

[0022] Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com