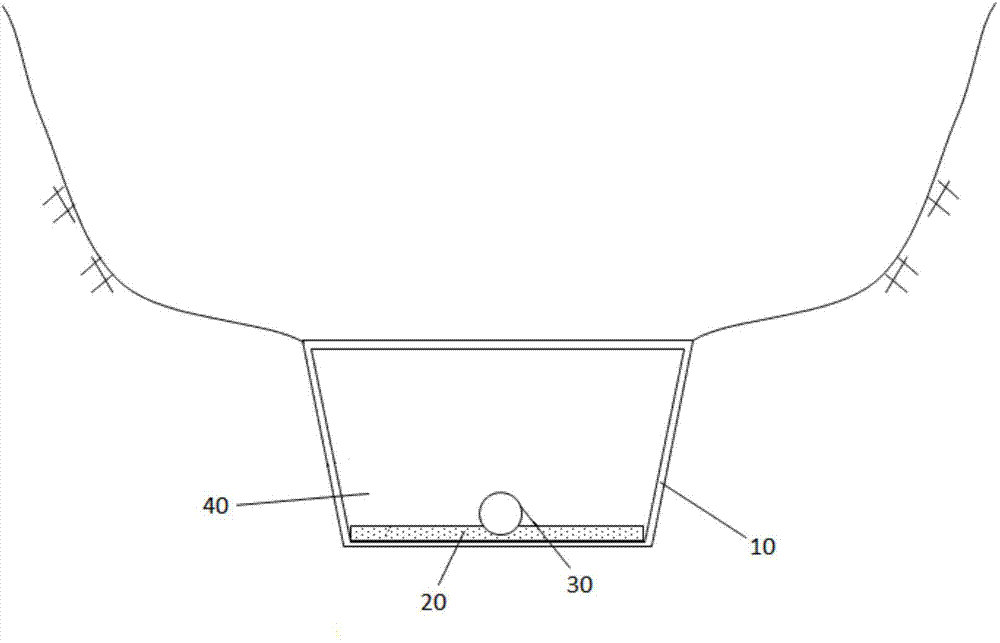

A tubular groundwater drainage blind ditch and its construction technology and application

A groundwater and blind ditch technology, applied in application, soil drainage, infrastructure engineering, etc., can solve problems such as prolonging construction period and increasing project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

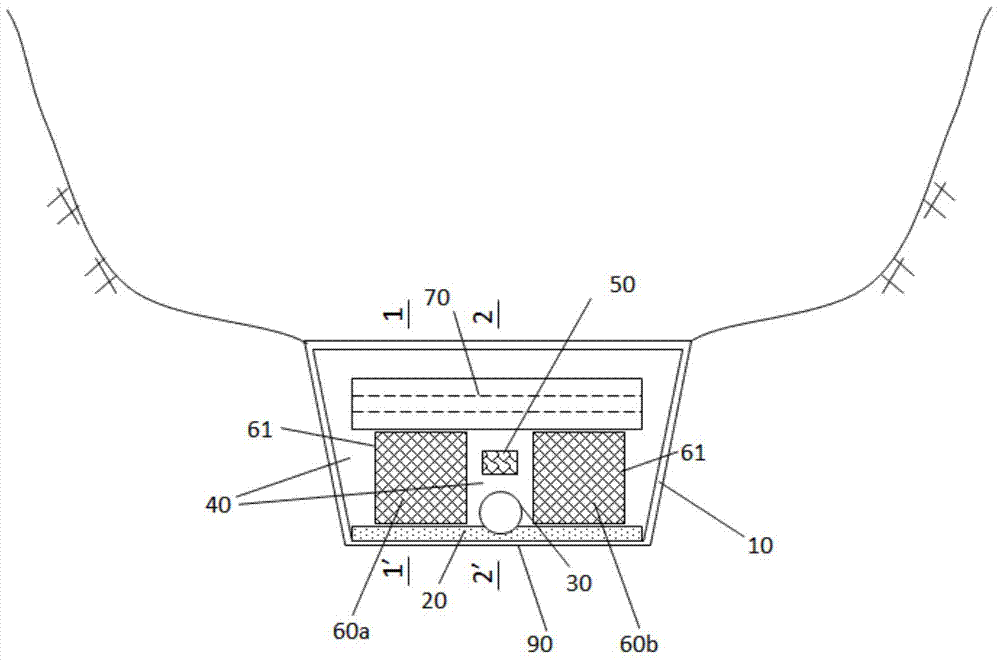

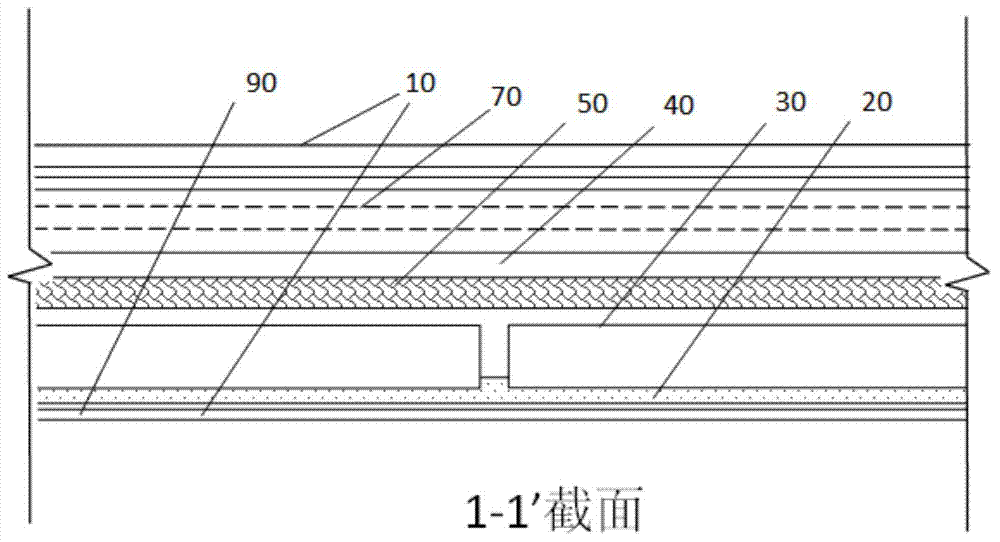

[0056] Embodiment 1-2 A construction technique for constructing the underground seepage drainage ditch described in Embodiment 1-1. The process is carried out in full accordance with the steps of the process described in the "Summary of the Invention" above. In order to keep the text concise and avoid repetition, only the key operations and technical data of each step are listed below.

[0057] Specific construction steps:

[0058] In step 1, the lower bottom width, upper bottom width and depth of the foundation trench 90 are 3.30m, 10.0m and 5.0m respectively, and the bottom surface of the foundation trench 90 should ensure that the longitudinal slope is 2%;

[0059] In step 3, the thickness of the base layer 20 is 30cm;

[0060] In step 4, the distance between the left and right gabion piers 60a, 60b is 80cm;

[0061] In step five, the support angle of the bottom layer 20 of the foundation trench to support the pipe culvert 30 is 120°;

[0062] In step 6, the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com