Intelligent pipeline crossing pusher

A technology of intelligent pipeline and propulsion machine, which is applied in the direction of pipeline laying and maintenance, mechanical equipment, pipe/pipe joint/pipe fittings, etc., can solve problems such as hidden danger of overload, and achieve the effect of convenient operation, simple structure and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

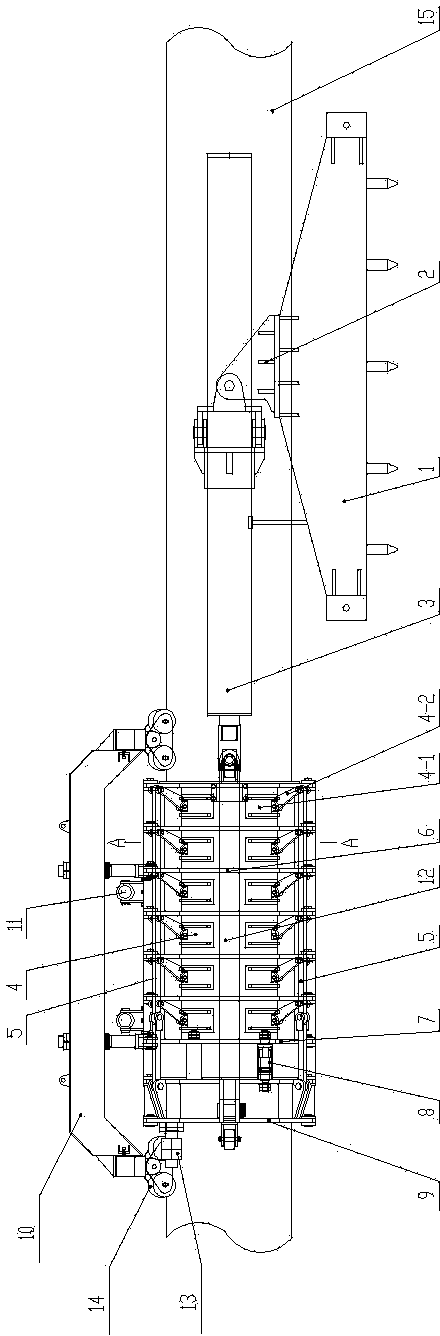

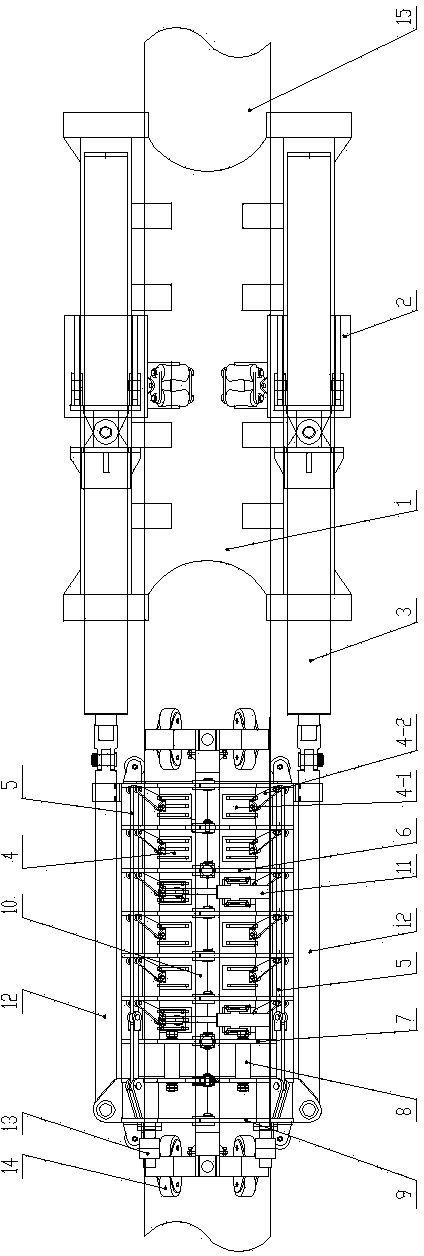

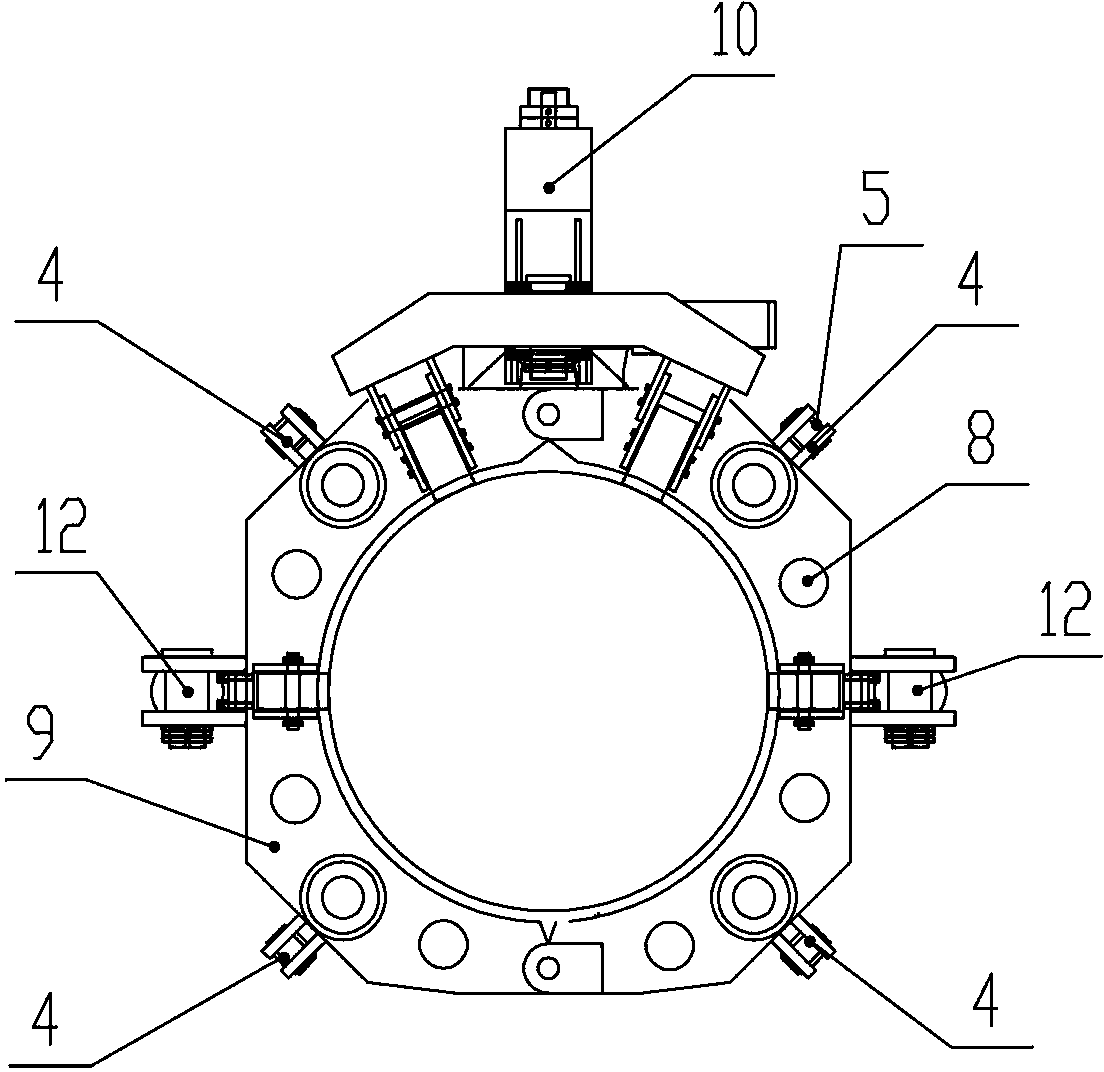

[0020] Such as Figure 1-4 As shown, the intelligent pipeline traverses the propulsion machine, which consists of a positioning seat (1), a bracket (2), 2 thrust cylinders (3), 24 thrust clamps (4), tie rods (5), and thrust frame (6) , Positioning guide seat (7), 8 clamping cylinders (8), thrust plate (9), walking device (10), 2 body opening and closing oil cylinders (11) and thrust rod (12).

[0021] The two thrust cylinders (3) are respectively hinged on both sides of the positioning seat (1) through the bracket (2), and can swing up and down with the steel pipe (15). The thrust cylinder (3) drives the thrust plate (3) through the thrust rod (12). 9) Exercise.

[0022] A closed thrust execution structure is composed of a thrust frame (6), a positioning guide seat (7) and a thrust plate (9). Make the overall force reasonable, uniform and high strength.

[0023] A total of 4 tie rods (5) are arranged, two symmetrically arranged on both sides of the steel pipe, one end of the tie ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com