Liquid anti-rolling positioning charging and circulating device for liquefied natural gas storage tank

A technology of liquefied natural gas and circulation device, which is applied in gas/liquid distribution and storage, gas processing application, installation device of container structure, etc., which can solve the increase of cost, the threat of storage tank safety, and the inability to specifically control the discharge level, etc. problem, to achieve the effect of preventing stratification and reducing the probability of tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

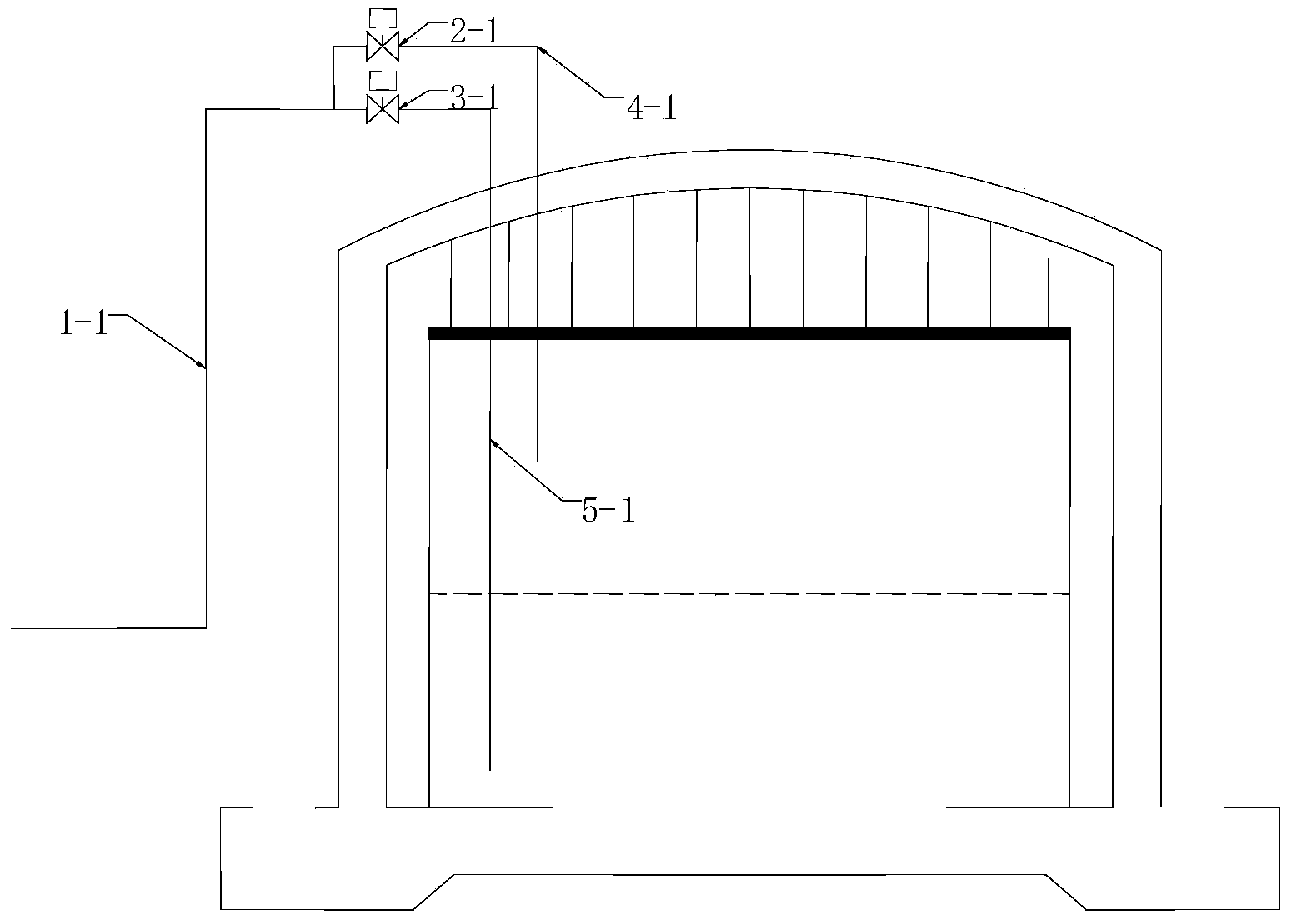

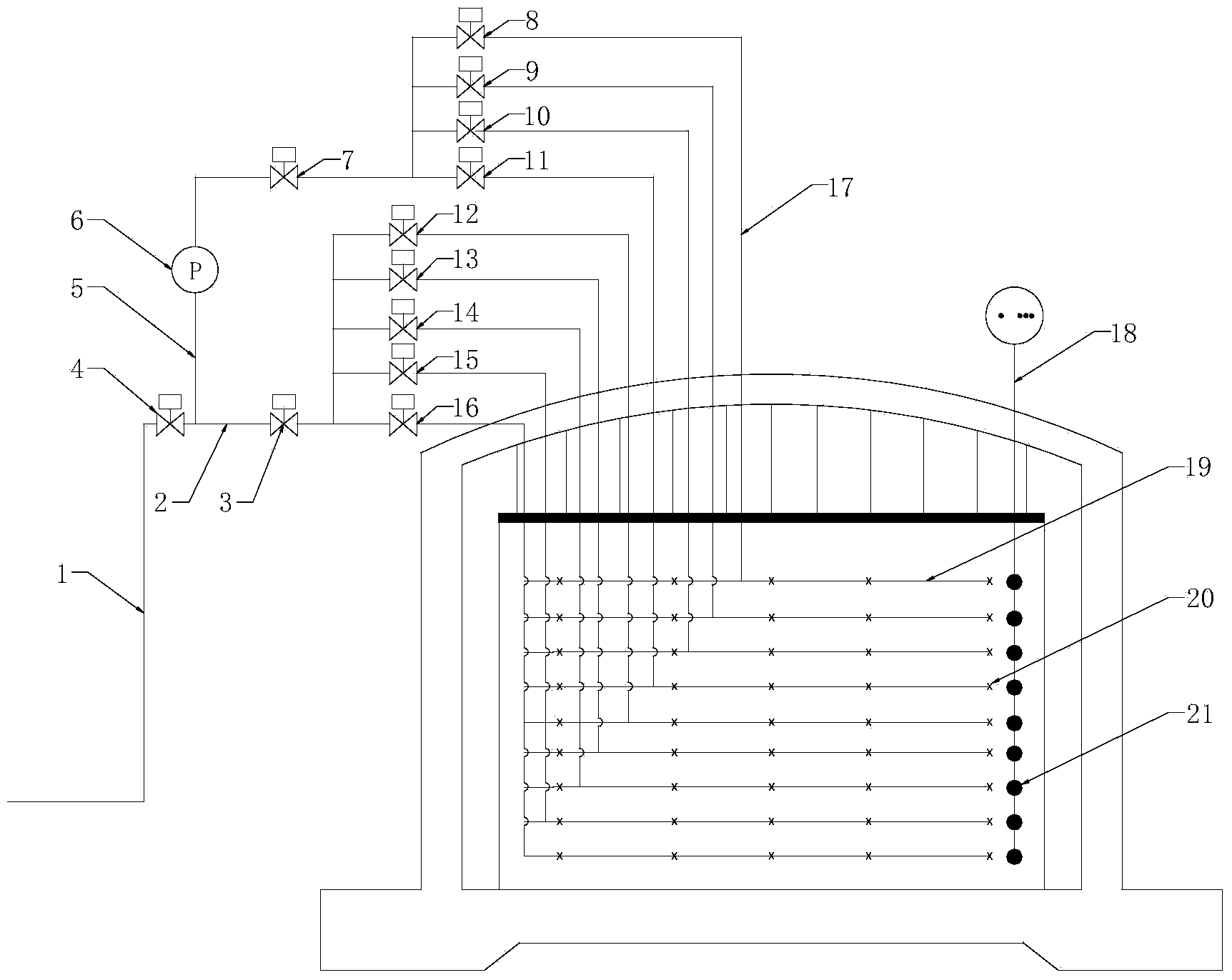

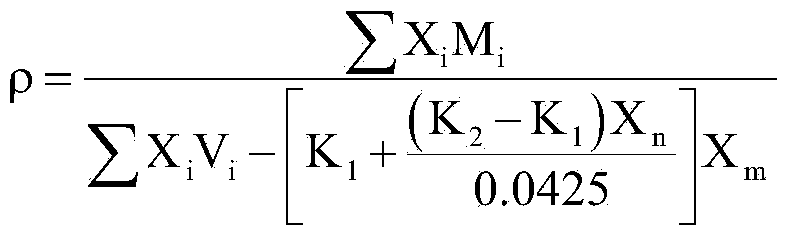

[0010] like figure 2 The liquid anti-rollover positioning filling and circulation device of the liquefied natural gas storage tank shown in the present invention includes a main unloading pipe 1, a heavy sub-unloading pipe 5 connected with the main unloading pipe 1, and a light weight unloading pipe. The sub-discharge pipe 2 is equipped with a main control switch valve 4 on the main discharge pipe 1, and the heavy and light sub-discharge pipes 5 and 2 are respectively installed with The switch control valves 7 and 3 of the light branch pipe, the outlet end of the heavy material branch pipe 5 are connected with the inlets of a plurality of heavy material branch pipes 17, the outlet end of the light branch pipe 2 is connected with the ports of a plurality of light material branch pipes. The inlet is connected, and multi-branch switching control valves 8, 9, 10, 11, 12, 13, 14, 15, 16 are installed on each heavy and light material branch pipe, from bottom to top in the LNG stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com