Nitrous oxide preparation device and method

A technology for nitrous oxide and preparation equipment, which is applied in the direction of nitrous oxide, chemical instruments and methods, nitrogen oxides/oxyacids, etc., which can solve the problems of untimely and accurate temperature control, difficult temperature control, and large temperature difference of materials. , to achieve the effect of improving heat transfer efficiency and reaction speed, facilitating precise control, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

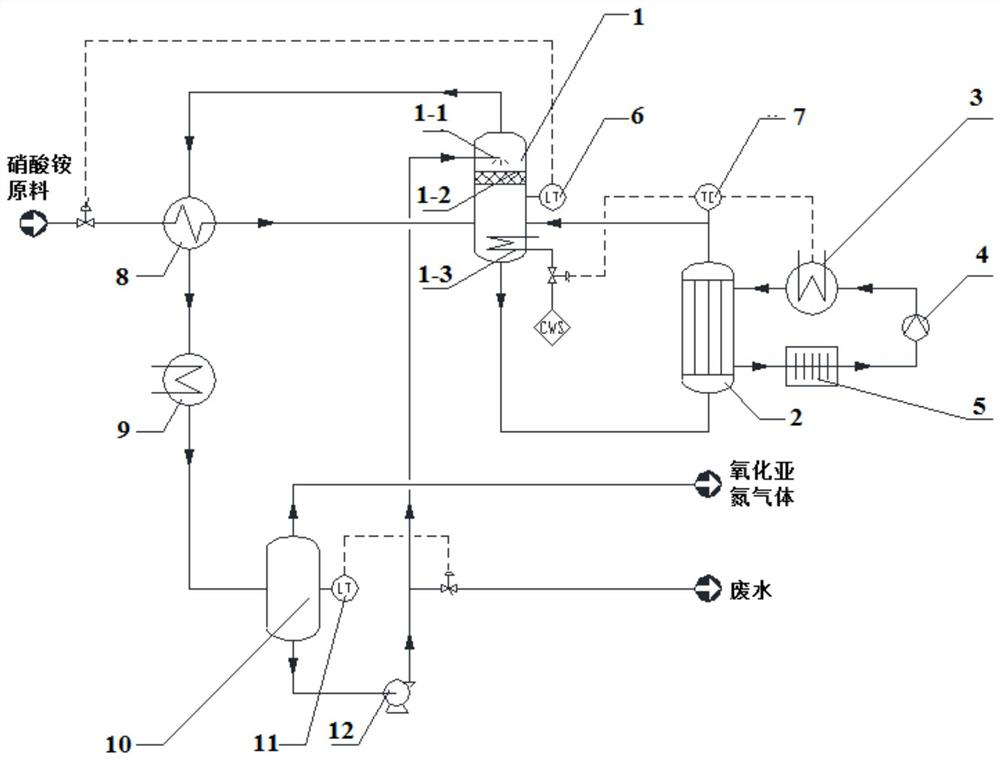

[0069] This embodiment provides a preparation device for nitrous oxide, the structural connection schematic diagram of the preparation device is as follows figure 1 As shown, it includes a reaction separator 1, a heating reactor 2 and a condensation collection unit. The lower outlet of the reaction separator 1 is connected to the lower inlet of the heating reactor 2, and the upper outlet of the heating reactor 2 is connected to the reaction separator. 1 is connected to the middle inlet, and the upper outlet of the reaction separator 1 is connected to the inlet of the condensation collection unit;

[0070] The upper part of the reaction separator 1 is provided with a spray assembly 1-1 and a packing assembly 1-2, and the spray assembly 1-1 is located above the packing assembly 1-2; the position of the reaction separator 1 is higher than the heating The location of Reactor 2.

[0071] The spray assembly 1-1 is a spray pipe, and the packing assembly 1-2 is a stainless steel wire...

Embodiment 2

[0084] This embodiment provides a preparation device for nitrous oxide, the preparation device includes a reaction separator 1, a heating reactor 2 and a condensation collection unit, the lower outlet of the reaction separator 1 and the lower inlet of the heating reactor 2 Connected, the upper outlet of the heating reactor 2 is connected to the middle inlet of the reaction separator 1, and the upper outlet of the reaction separator 1 is connected to the inlet of the condensation collection unit;

[0085] The upper part of the reaction separator 1 is provided with a spray assembly 1-1 and a packing assembly 1-2, and the spray assembly 1-1 is located above the packing assembly 1-2; the position of the reaction separator 1 is higher than the heating The location of Reactor 2.

[0086] The spray assembly 1-1 is a spray pipe, and the packing assembly 1-2 is a stainless steel corrugated orifice plate.

[0087] The heating reactor 2 is a heat exchange device, and a fan 4 is connecte...

Embodiment 3

[0098] This embodiment provides a method for preparing nitrous oxide, which is carried out using the device in Example 1, comprising the following steps:

[0099] (1) Preheating the liquid ammonium nitrate raw material with a temperature of 125°C and a water content of 7wt%, and then entering the reaction separator 1 for decomposition reaction, and part of the raw material will also enter the heating reactor 2 for decomposition reaction, the decomposition The reaction temperature is 250°C, and the reaction materials circulate in the reaction separator 1 and the heating reactor 2. The reaction materials enter the heating reactor 2 and are indirectly heated by hot air, and the heat released by the reaction is taken away by the hot air, and the reaction separation The temperature of the device 1 is controlled by passing cooling water into the cooling assembly 1-3, and the reaction products include nitrous oxide, water, ammonia gas and nitric acid, and the raw material droplets ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com