Self-circulation vertical speed changer

A speed changer and self-circulation technology, applied in the field of speed changers, can solve the problems of difficulty in sealing the speed changer case body, shortening the service life of the speed changer, shortening the service life of the seals, etc., and achieves the effects of simple structure, extended life and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

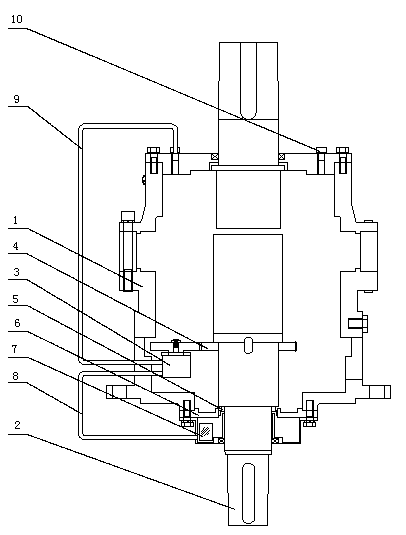

[0017] See figure 1 , a self-circulating vertical transmission, including a box body 1 with air holes on the top, an input shaft 2 and a gear pump 3 arranged in the box body 1, and a power unit installed on the input shaft 2 and meshed with the gear of the gear pump 3 Gear 4; a breather cap 10 is arranged in the vent hole; an oil throwing ring 5 is connected to the lower part of the input shaft 2; Oil collection cover 7 is arranged below 5; oil suction pipe 8 and oil outlet pipe 9 are arranged on gear pump 3, and the bottom end of oil suction pipe 8 is connected to the lower part in box body 1, and its top is connected with gear pump 3, and oil outlet pipe 9 The bottom end is connected with the gear pump 3, and its top end is connected to the upper part in the casing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com