Heating laminate floor

A floor and heating paper technology, applied in the field of wood flooring, can solve the problems of safety hazards and heating efficiency, and achieve the effects of high electrothermal conversion efficiency, uniform heating, and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

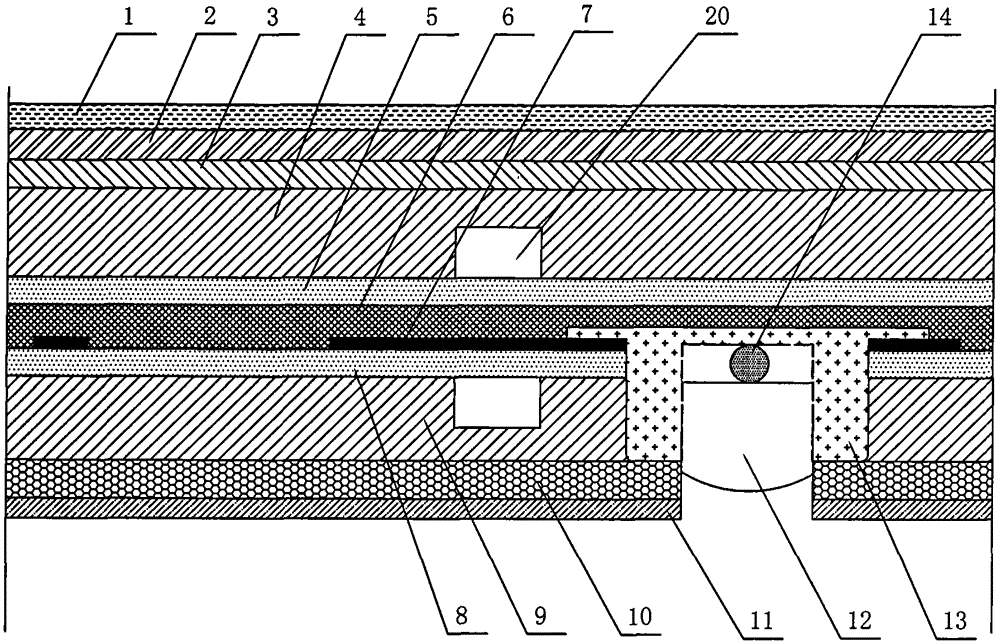

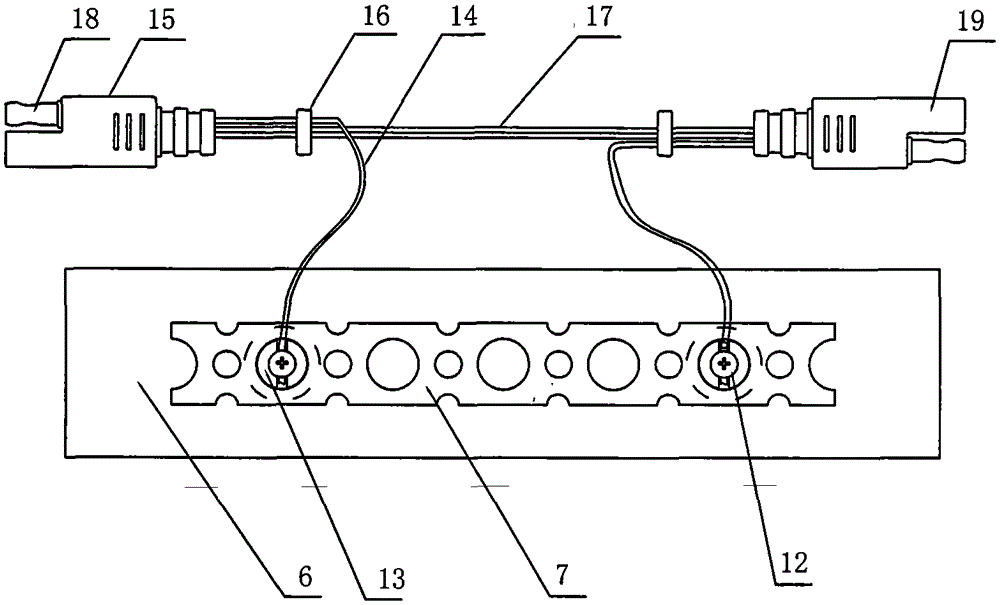

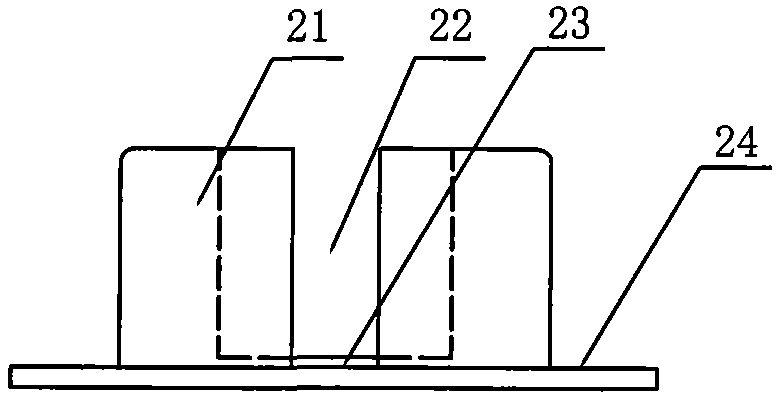

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0018] Examples such as figure 1 , 2 , 3, and 4, a heating reinforced floor, including wear-resistant paper 1, decorative paper 2, balance paper 3, upper substrate board 4, upper rubber-impregnated paper 5, far-infrared carbon fiber heating paper 6, lower rubber-impregnated Paper 8, lower substrate board 9, heat insulation layer 10, aluminum foil 11, conductive metal sheet 7 for heating floor, connecting terminal 13 for heating floor and waterproof two-way male and female plug power cord 15; Mill a horizontal exhaust groove 20 at about 1 / 2 of the length direction of the lower base plate 9, and between the upper base plate 4 and the lower base plate 9, there are upper dipping paper 5, far-infrared carbon fiber heating paper 6 and Under-dipping rubberized paper 8; under the lower base material plate 9, an insulating layer 10 and an aluminum foil laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com