Routing inspection method and routing inspection system with image uploading function

An image and function technology, applied in the field of inspection management, can solve problems such as inconvenience to remotely judge faults, and achieve the effect of facilitating accurate and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

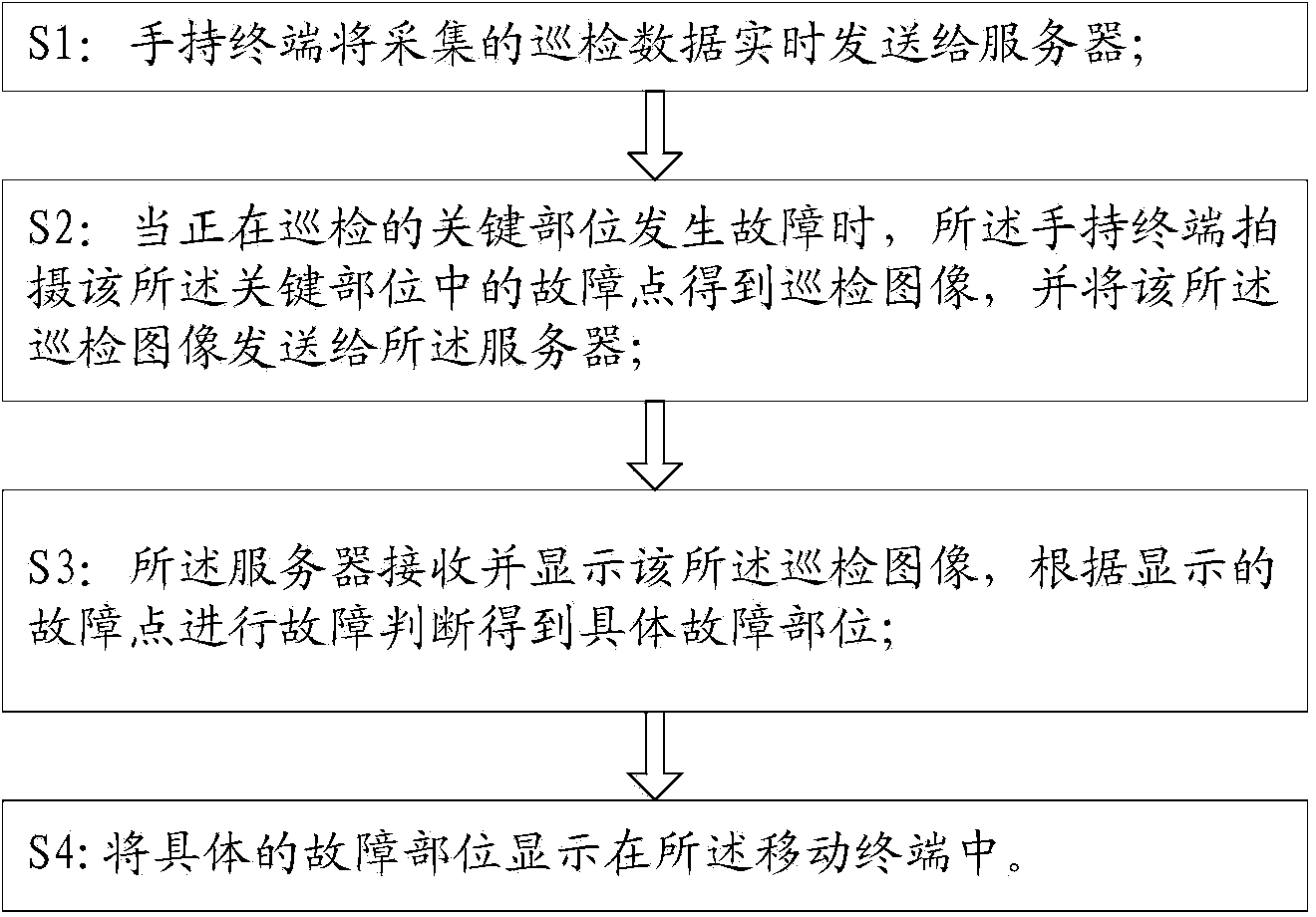

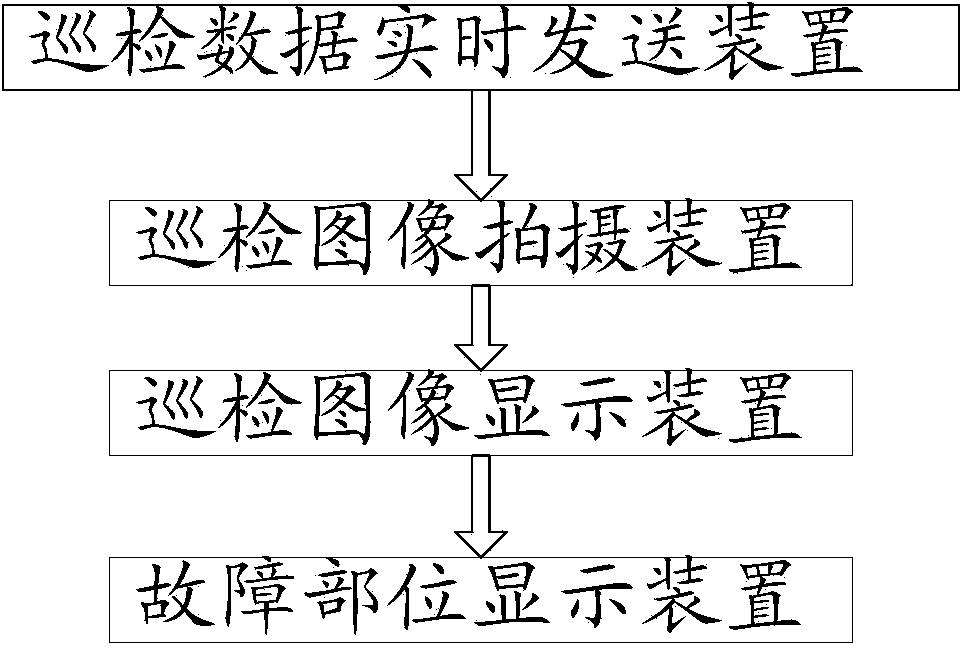

[0051] An inspection method with image upload function, such as figure 1 shown, including the following steps:

[0052] S1: The handheld terminal sends the collected inspection data to the server in real time. The inspection data includes part ID, inspection item, inspection item data and user ID.

[0053] S2: When a fault occurs in a key part being inspected, the handheld terminal captures the fault point in the key part to obtain an inspection image, and sends the inspection image to the server.

[0054] S3: The server receives and displays the inspection image, and performs fault judgment according to the displayed fault point to obtain a specific fault location.

[0055] S4: Displaying the specific fault location in the mobile terminal. As a specific implementation of this embodiment, when the specific fault location is displayed in the mobile terminal, it can be displayed in the mobile terminal by describing the fault location in words, or by displaying a partial pictu...

Embodiment 2

[0058] As an embodiment of the present invention, on the basis of Embodiment 1, the step S4 further includes the following steps:

[0059] S41: The server circles specific fault locations in the inspection image to generate a fault circle map image, and sends the fault circle map image to the mobile terminal. As a specific implementation manner, when the specific fault location is circled, a circle can be drawn in the inspection image by using the mouse to circle the specific fault location to generate a fault circle map image.

[0060] S42: The mobile terminal to which it belongs receives and displays the fault circle diagram image.

[0061] The present invention can circle the specific fault location in the inspection image, and the inspection personnel using the handheld terminal can accurately determine the specific fault location where the fault occurs through the fault circle image displayed on the handheld terminal, It has the advantage of being convenient for inspecti...

Embodiment 3

[0063] As an embodiment of the present invention, on the basis of Embodiment 2, the inspection image is an inspection video.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com