Method and device for deicing direct current transmission line of extra-high-voltage direct current project

A DC transmission line, ultra-high voltage DC technology, applied in the direction of emergency protection circuit devices, cable installation, overhead installation, etc., can solve the problem of implementation, the DC line current cannot meet the ice melting requirements, and the ice melting power cannot be transported, etc. problem, to achieve the effect of preventing serious impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

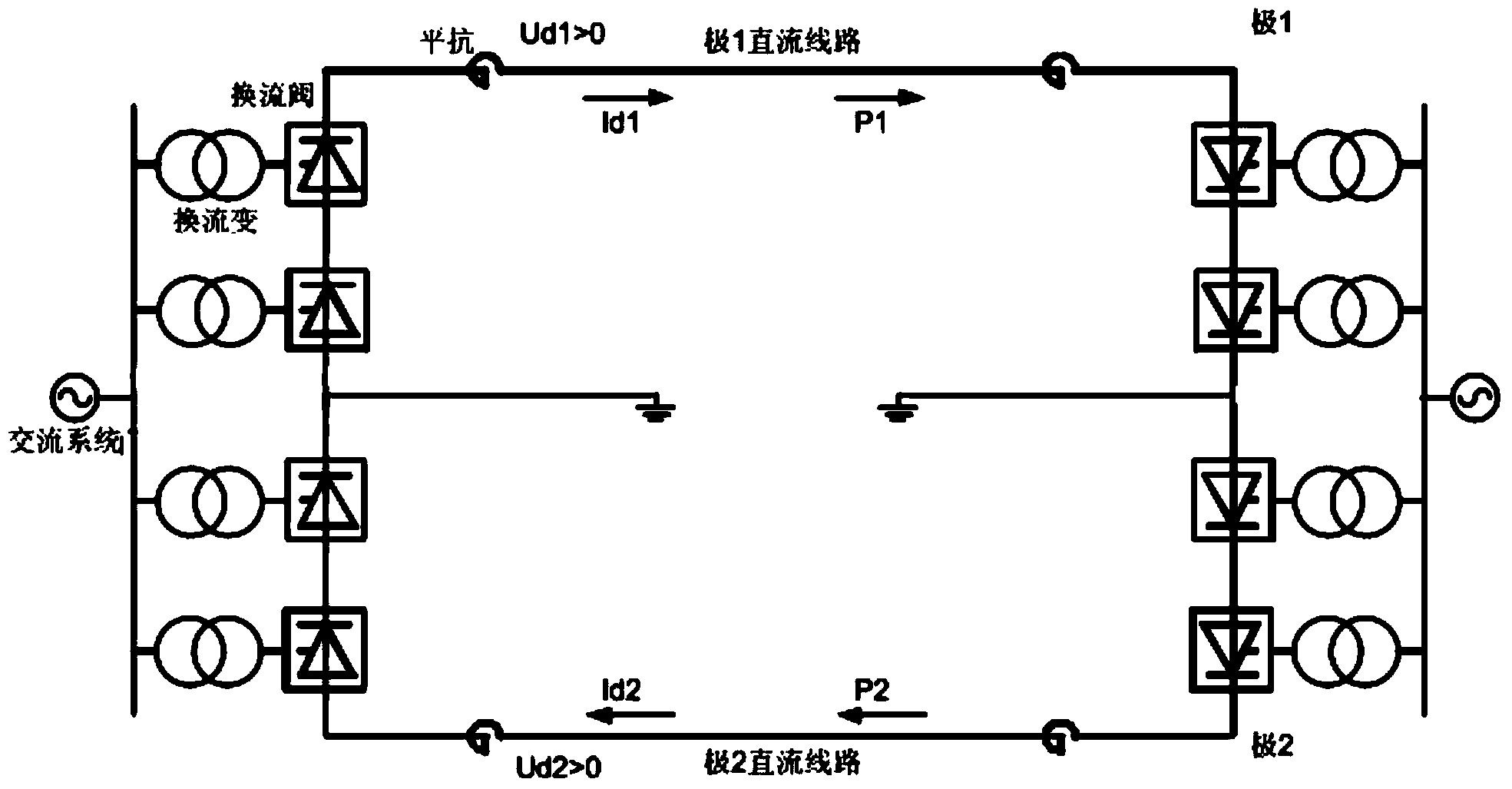

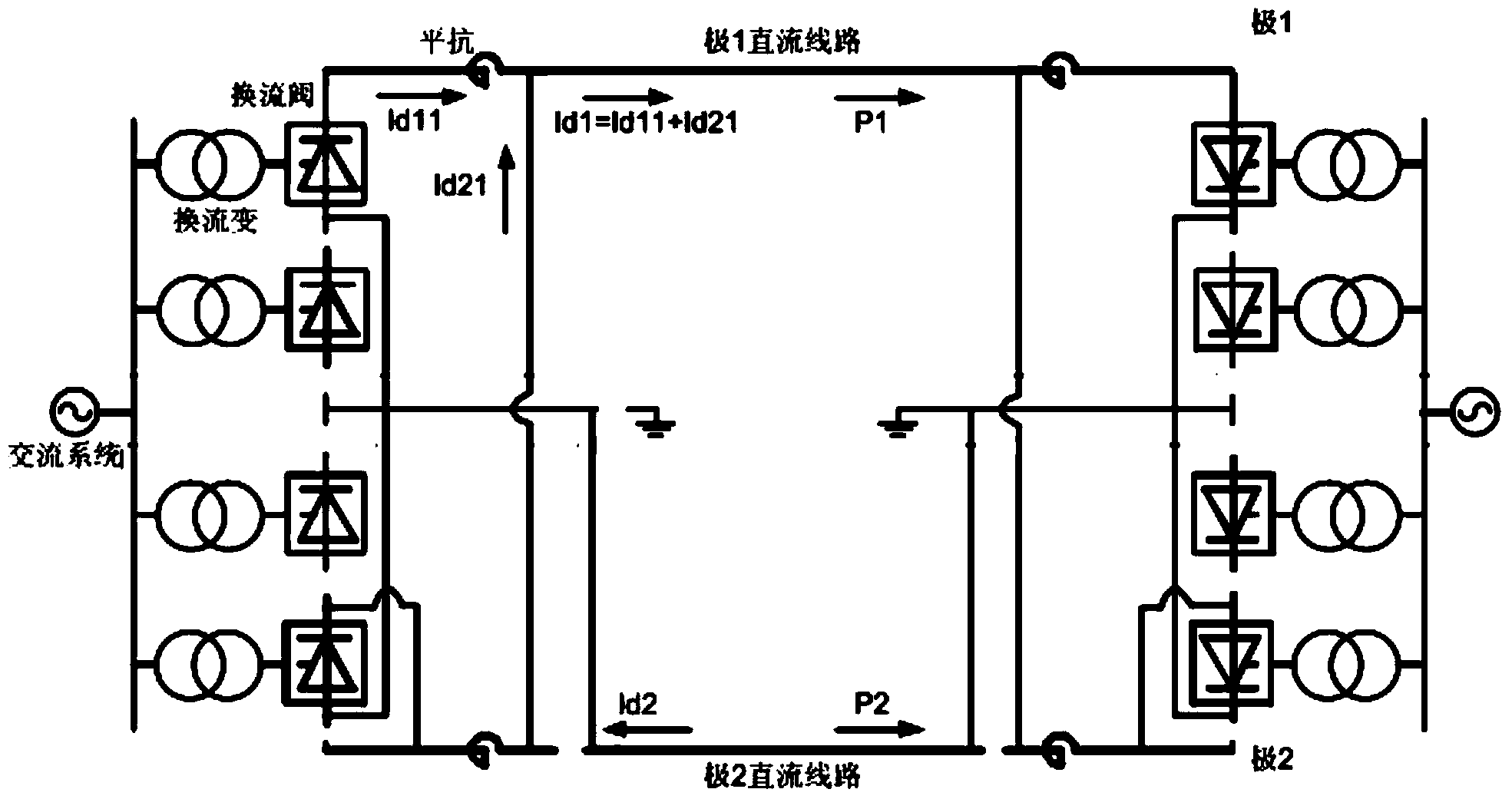

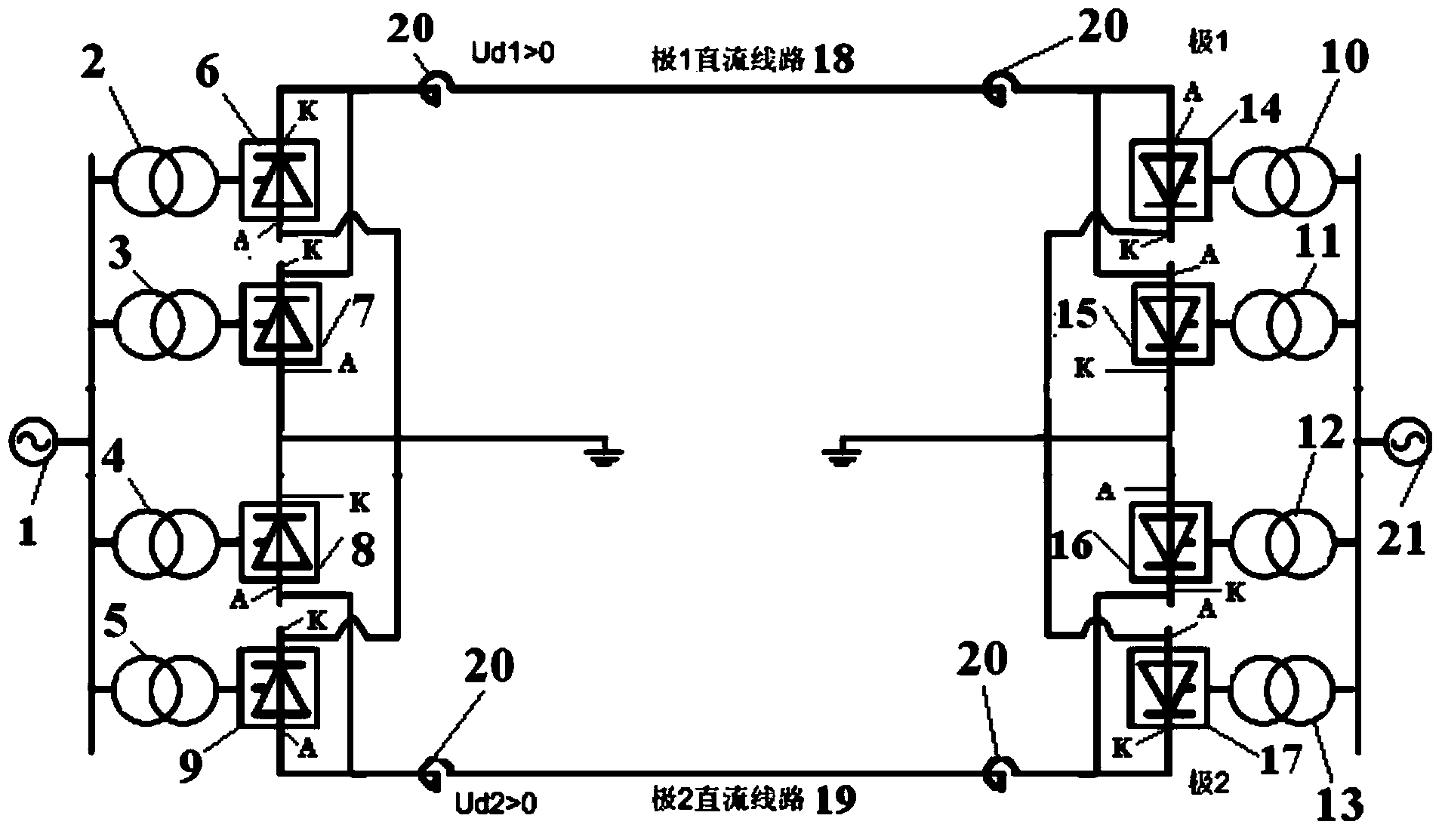

[0019] Such as image 3 , Figure 4 As shown, the present invention provides a deicing device for UHV DC engineering DC transmission lines, which includes a transmitting end AC system 1, a first converter transformer 2, a second converter transformer 3, a third converter transformer 4, a Four converter transformers 5, first converter valve 6, second converter valve 7, third converter valve 8, fourth converter valve 9, fifth converter transformer 10, sixth converter transformer 11, seventh Converter transformer 12, eighth converter transformer 13, fifth converter valve 14, sixth converter valve 15, seventh converter valve 16, eighth converter valve 17, pole 1 DC transmission line 18, pole 2 DC Transmission line 19, smoothing reactor 20 and AC system 21 at the receiving end. Wherein, when the voltage Ud1 at both ends of pole 1 DC transmission line 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com