Automatic electric cooker with electrode heating function

A technology of electrode heating and electric rice cooker, which is applied in heating devices, cooking utensils, household utensils, etc., can solve the problem of high cost, achieve proper heating time, reduce cost, and improve the effect of food flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

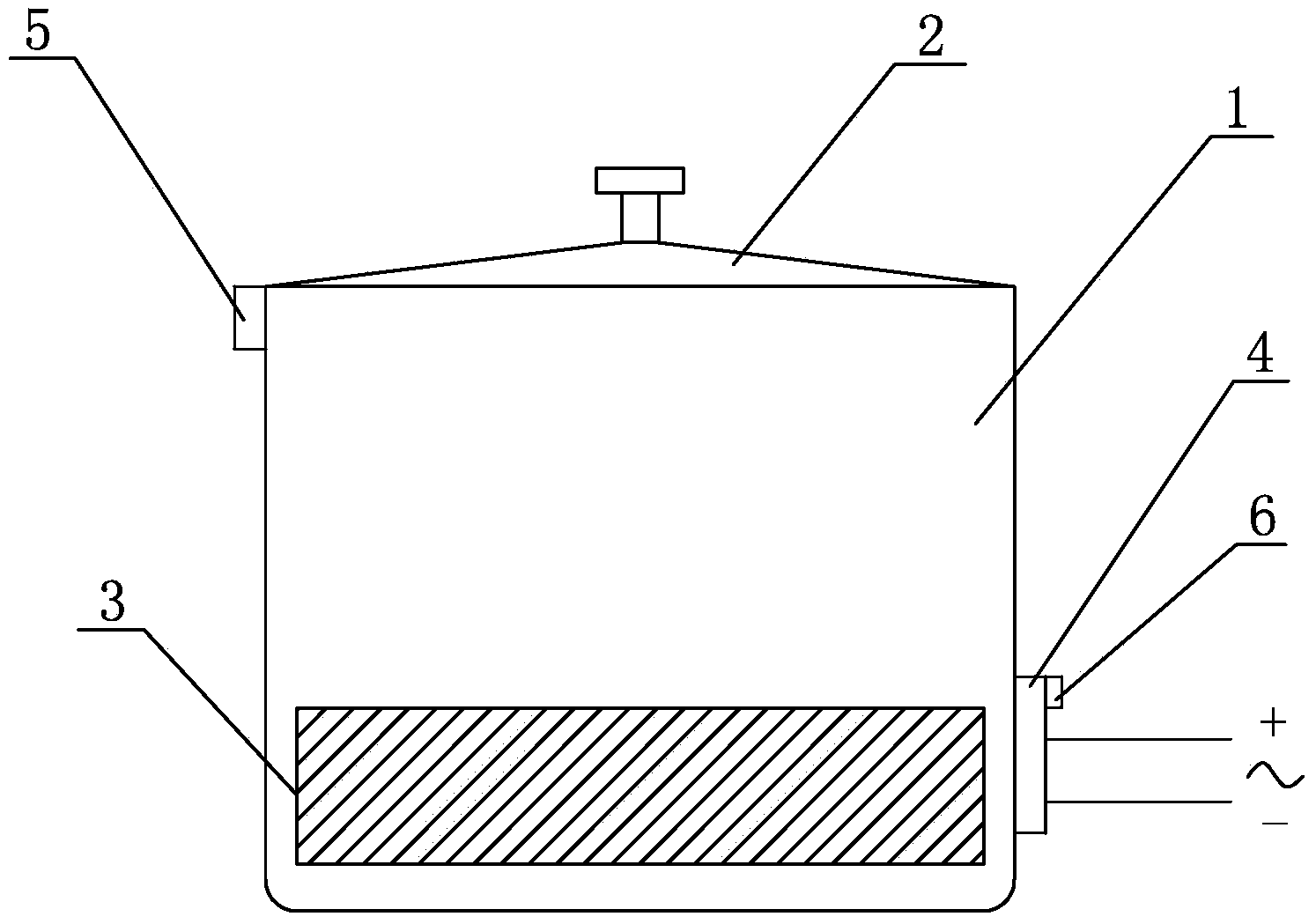

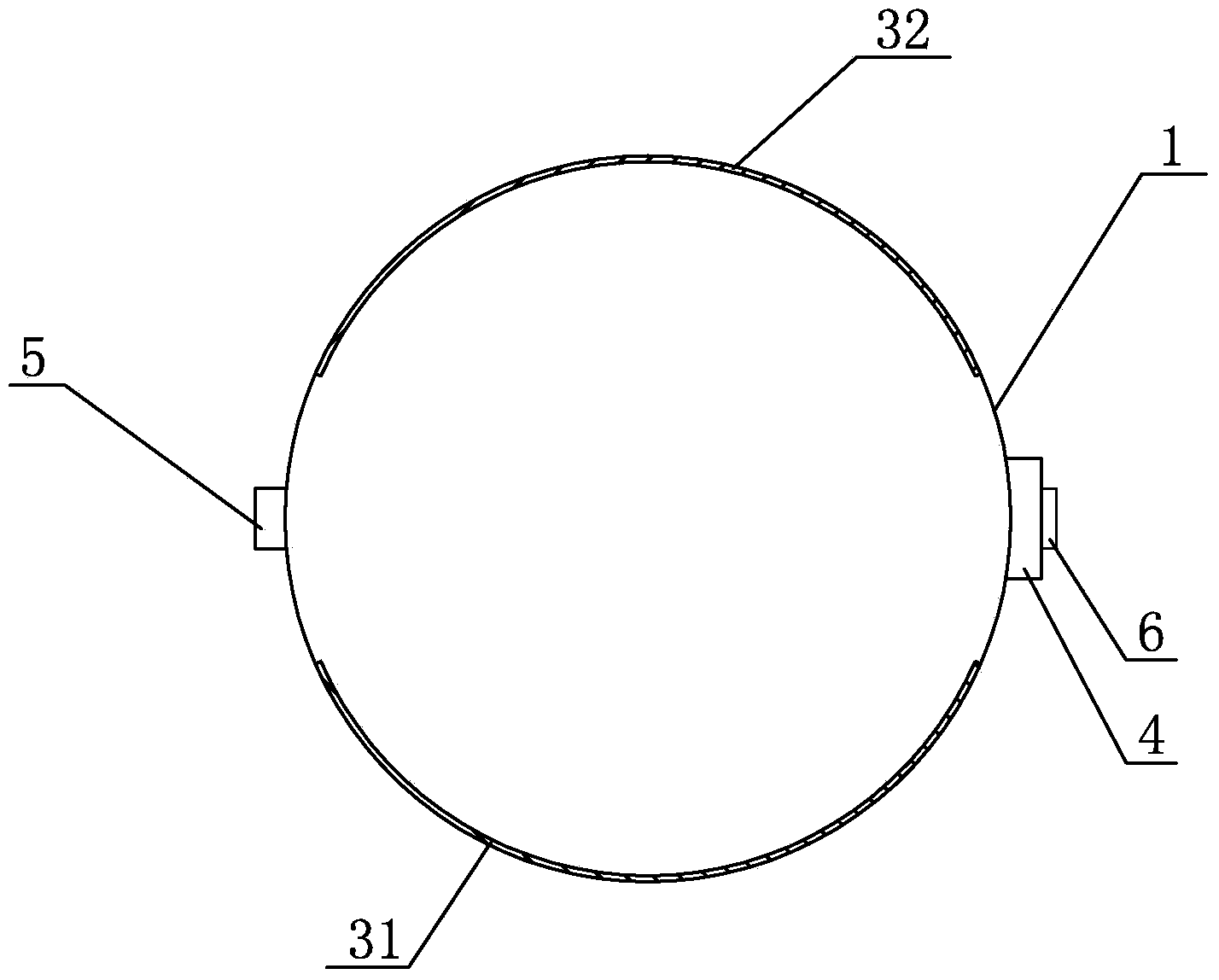

[0029] refer to figure 1 , figure 2 , an electrode heating automatic rice cooker provided by the present invention includes a pot body 1 and a pot cover 2 made of insulating materials, the pot body 1 is a container with an upper opening, and the pot cover 2 is closed at the opening above the pot body 1 . The inner wall of the pot body 1 is provided with an exposed electrode group 3, and the electrode group 3 includes a first electrode 31 and a second electrode 32 separately arranged. In this embodiment, both the first electrode 31 and the second electrode 32 are arranged on the pot body 1. On the inner side wall of , and the first electrode 31 and the second electrode 32 are arranged symmetrically. The first electrode 31 and the second electrode 32 are respectively connected to the output terminals of the control circuit. The pot body 1 is provided with a control circuit 4 for controlling the operation of the first electrode 31 and the second electrode 32 , and the control ...

no. 2 example

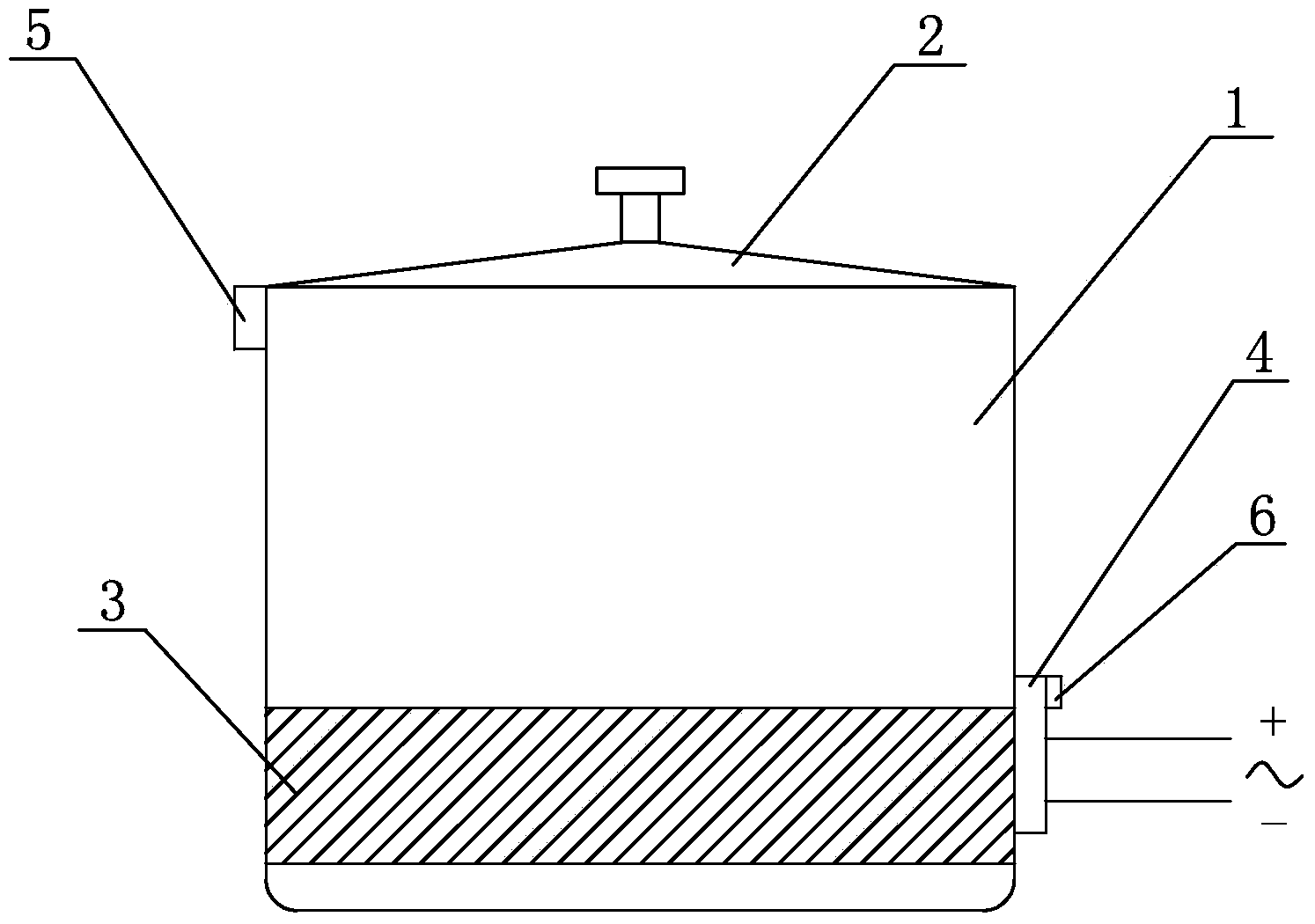

[0031] refer to image 3 , Figure 4 , the second embodiment provided by the present invention, the difference between this embodiment and the first embodiment is that the arrangement of the electrode group 3 is different. In this embodiment, the first electrode 31 is arranged on the inner wall of the pot body 1, and the pot body 1 The bottom is provided with an inner layer second electrode 32A, a middle layer second electrode 32B and an outer layer second electrode 32C in sequence from the inside to the outside, and the inner layer second electrode 32A, the middle layer second electrode 32B and the outer layer second electrode 32C Arranged in a concentric ring shape, different second electrodes can be switched and used according to the conductivity of the water in the pot body 1 during the cooking process, so as to maintain a stable heating power. Other structures of this embodiment are the same as those of the first embodiment.

[0032] The method of using the electrode he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com